Film forming method of ti-series film

A film-forming method and film-forming technology, used in gaseous chemical plating, coatings, electrical components, etc., can solve the problems of low temperature and uneven film thickness, and achieve the effect of suppressing the deviation between surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

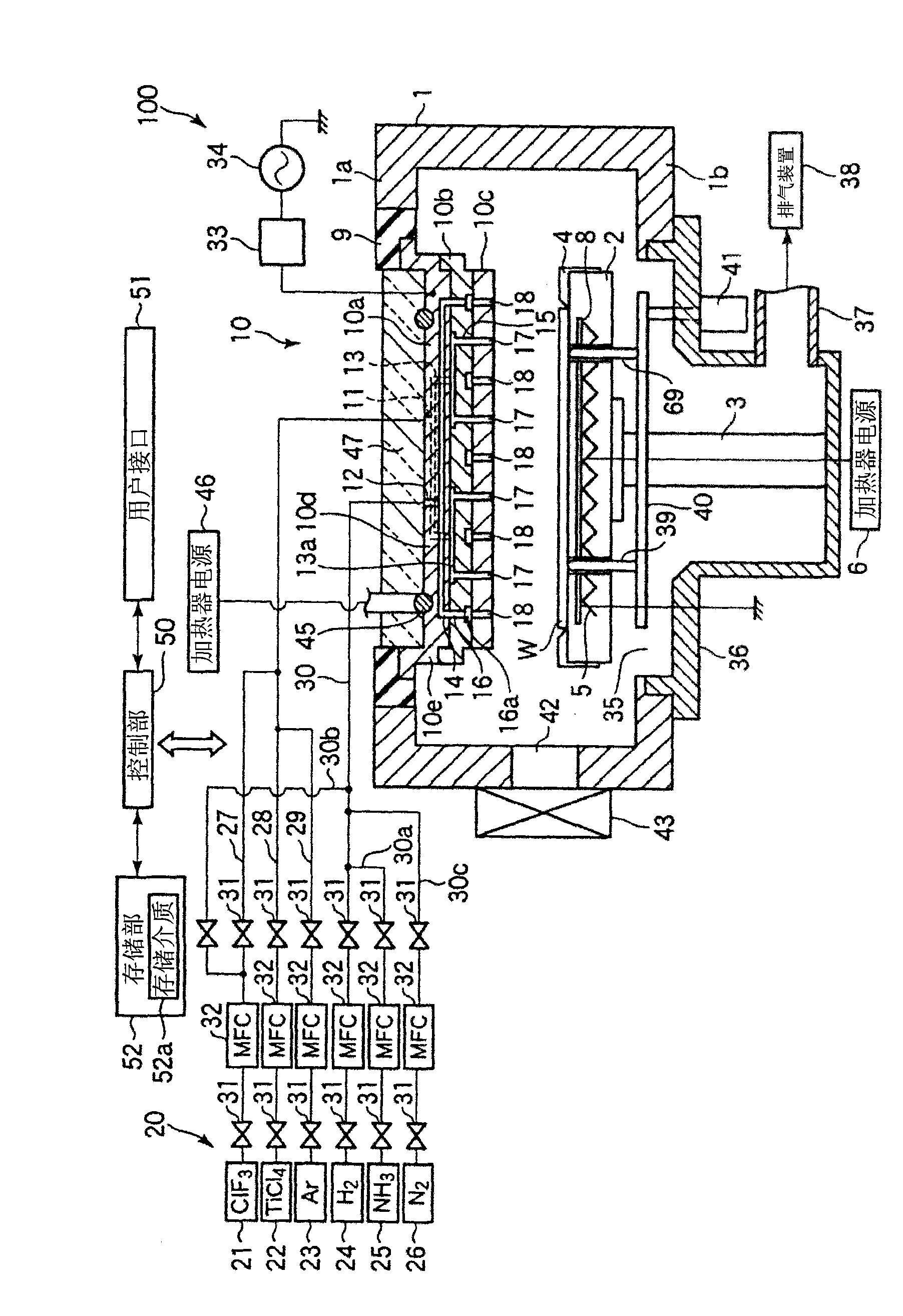

[0046] figure 1It is a schematic cross-sectional view showing an example of a Ti film forming apparatus used for implementing a Ti film forming method according to an embodiment of the present invention. The Ti film forming apparatus 100 is configured as a plasma CVD film forming apparatus that forms a plasma by forming a high-frequency electric field on parallel plate electrodes and performs CVD film formation.

[0047] This Ti film forming apparatus 100 has a substantially cylindrical chamber 1 . Inside the chamber 1, a susceptor 2 made of AlN for horizontally supporting a wafer W which is a substrate to be processed is arranged in a state of being supported by a cylindrical support member 3 provided at the lower central portion thereof. A guide ring 4 for guiding the wafer W is provided on the outer edge of the susceptor 2 . In addition, a heater 5 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com