Aluminum alloy board

An aluminum alloy plate, quality technology, applied in the superstructure, transportation and packaging, vehicle parts, etc., can solve problems such as insufficient suppression countermeasures

Inactive Publication Date: 2010-03-31

KOBE STEEL LTD

View PDF2 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0023] However, in Patent Document 1, the stepped serrations are made as slight as possible (the description of the evaluation of the stepped serrations according to the examples of Patent Document 1), therefore, parallel bands as one

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

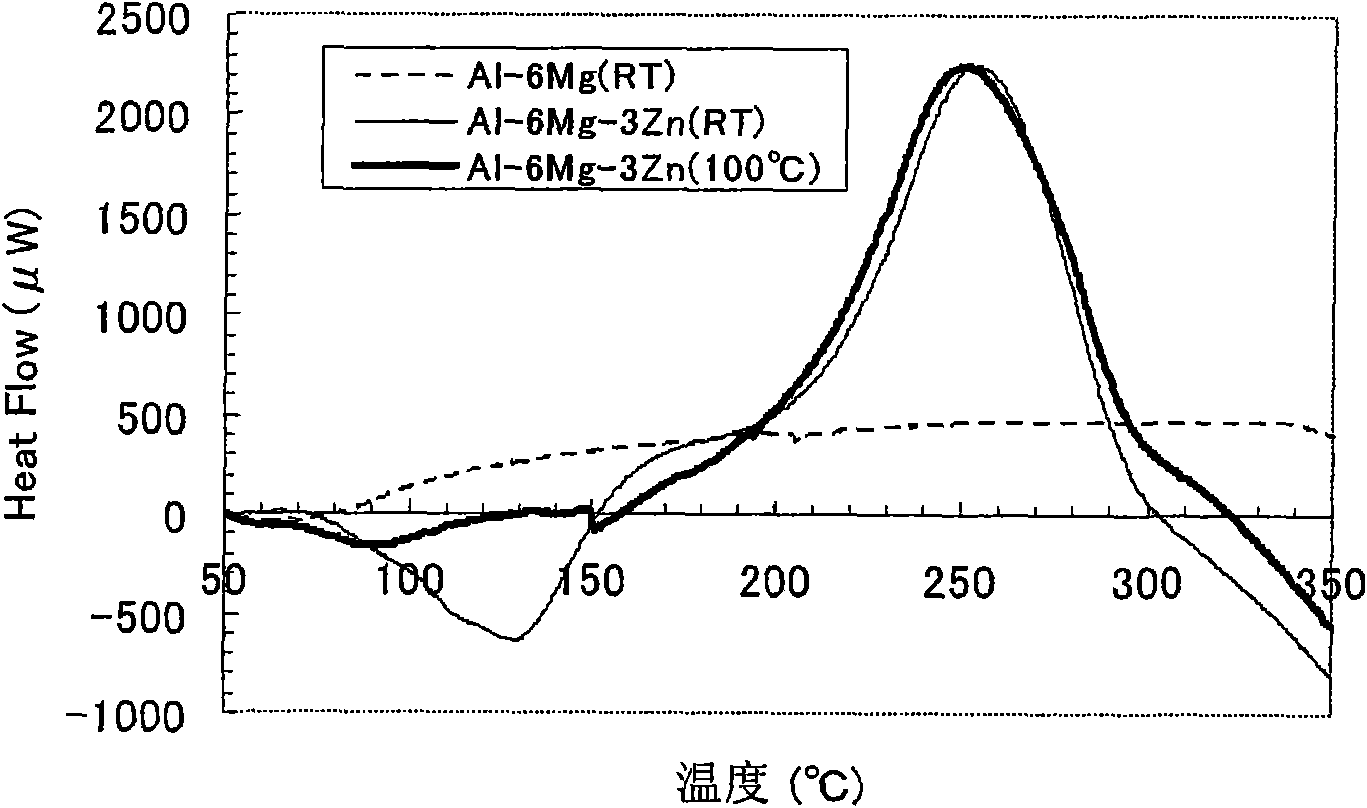

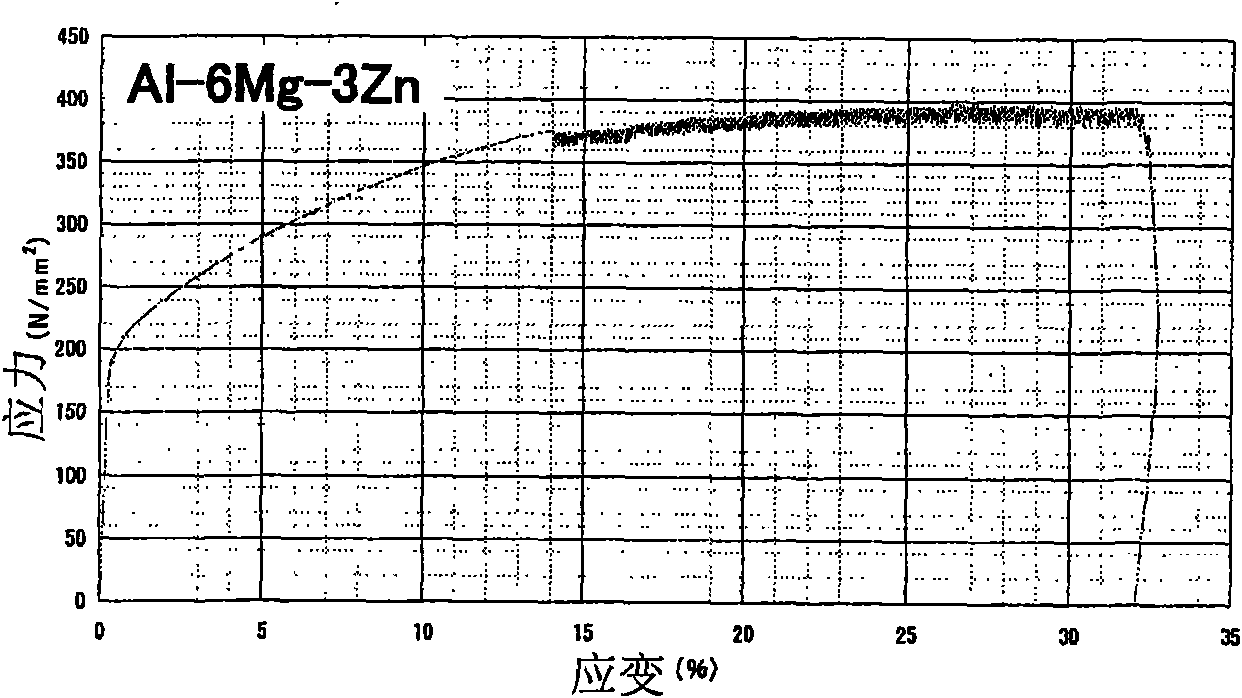

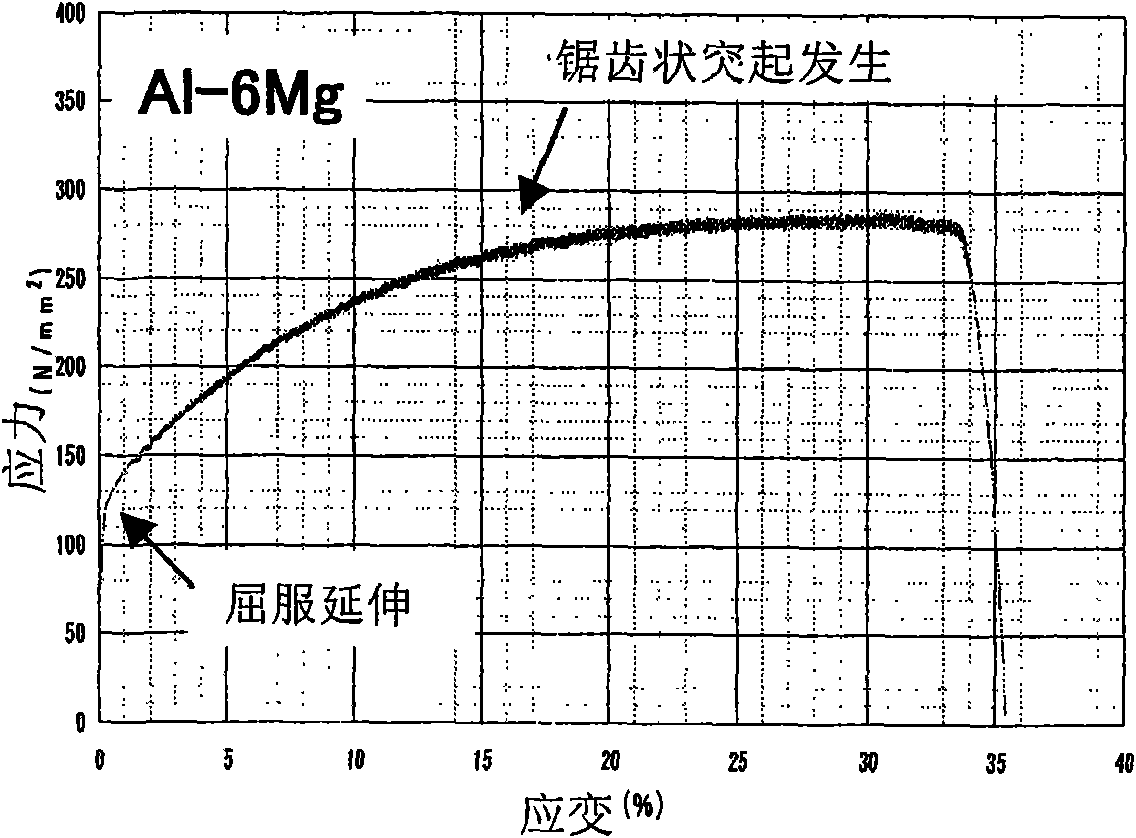

The invention provides a Al-Mg aluminum alloy board with a fewer tensile strain marks, and an excellent shaping property. The aluminum alloy board is exerted with a definite prestrain in advance and then is molded by extrusion, and the board has a certain amount of Mg, and the heat absorption peak value height of the heating curve between 100-150 DEG C. from solid phase obtained in the heat changeduring the board melting process determined by the differential thermal analysis is above 28 muW/mm<3>, thereby inhibiting tensile strain marks during extrusion molding under a rigor shaping condition.

Description

technical field [0001] The present invention relates to an aluminum alloy sheet, and particularly relates to an Al-Mg based aluminum alloy sheet and a method for forming the aluminum alloy sheet, which have less occurrence of stretcher strain marks and are excellent in formability. The aluminum alloy sheet referred to in the present invention refers to a hot-rolled sheet and a cold-rolled sheet, and refers to a state (non-tempered) after rolling, or an aluminum alloy sheet subjected to tempering such as annealing. In addition, aluminum is also called Al below. Background technique [0002] In recent years, social demands for weight reduction of vehicles such as automobiles have been increasing from the viewpoint of consideration of the global environment and the like. In order to meet this demand, the application of aluminum materials in addition to steel materials such as steel plates has also been studied as materials for automotive panels, especially large body panels (i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/06C22C21/10C22C21/08B62D29/00

CPCB62D29/00C22C21/06C22C21/08C22C2202/00C22F1/047

Inventor 松本克史长尾护

Owner KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com