Foam separator for preprocessing produced water

A foam separator and pretreatment technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of low separation rate and incomplete separation, and achieve the effect of improving the decomposition rate, increasing the volume ratio of foam, and enhancing the stability of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

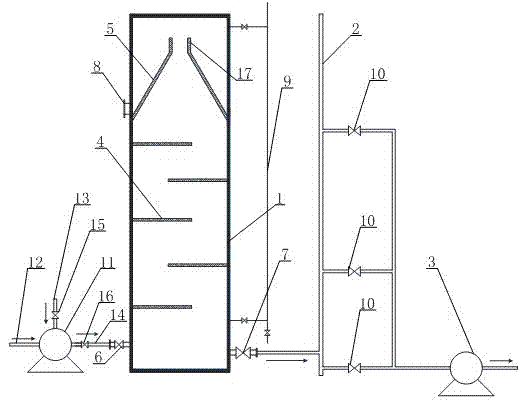

[0024] Such as figure 1 As shown, a foam separator for pretreatment of produced water includes an aeration pump, a separation cylinder 1 connected to the bottom of the aeration pump, a communication pipe 2 connected to the bottom of the separation cylinder, and a communication pipe connected to the The outlet pump 3; the separation cylinder is provided with more than two baffles 4, and the top inside the separation cylinder is provided with a conical foam collector 5 for collecting foam; one side of the separation cylinder bottom is provided There is a water inlet valve 6 connected with the aeration pump, the other side is provided with a water outlet valve 7 connected with the communication pipe, and the side of the upper end of the separation cylinder is provided with a foam liquid outlet 8; the separation cylinder is also provided with There is a liquid level gauge 9 .

[0025] Wherein, the connecting pipe is arranged vertically, and a liquid adjusting valve 10 connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| foam stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com