Cross-shape profiled-section polyester fiber multilayer quick-filtering nonwoven

A polyester fiber, fast filtration technology, applied in filtration and separation, membrane filters, non-woven fabrics, etc., can solve the problem of insufficient fiber strength in special-shaped sections, and achieve the effect of improving the effect, improving the filtration efficiency, and enhancing the connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] This embodiment is a cross-shaped non-woven polyester fiber multi-layer fast filter fabric, which provides a multi-layered structure for deep filtration. The structure of the cross-shaped cross-section fiber is used to generate grooves, so that the efficiency of liquid filtration can be improved and the lateral flow can be reduced. The consumption of textile fabrics has the advantages of surface filtration and depth filtration at the same time. Its preparation process comprises the following steps:

[0015] 1) Take 40 parts of acrylic resin, add 0.5 parts of ammonia water and 59.5 parts of water in sequence and mix evenly to obtain a resin solution;

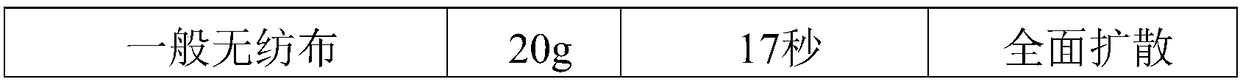

[0016] 2) Use 2D*51mm cross-section polyester as the raw material, output the cotton net according to the general non-woven fabric process, and keep the fibers as smooth as possible, and control the cotton weight of the carding machine to 10g / m 2 ~11g / m 2 , and at the same time reduce the speed of the main cylinder wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com