Yarn delivery device with overload-protected fastening gripper

A clamper and equipment technology, applied in the field of yarn conveying equipment, can solve problems such as unraveling, yarn conveying equipment inoperability, clamper deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

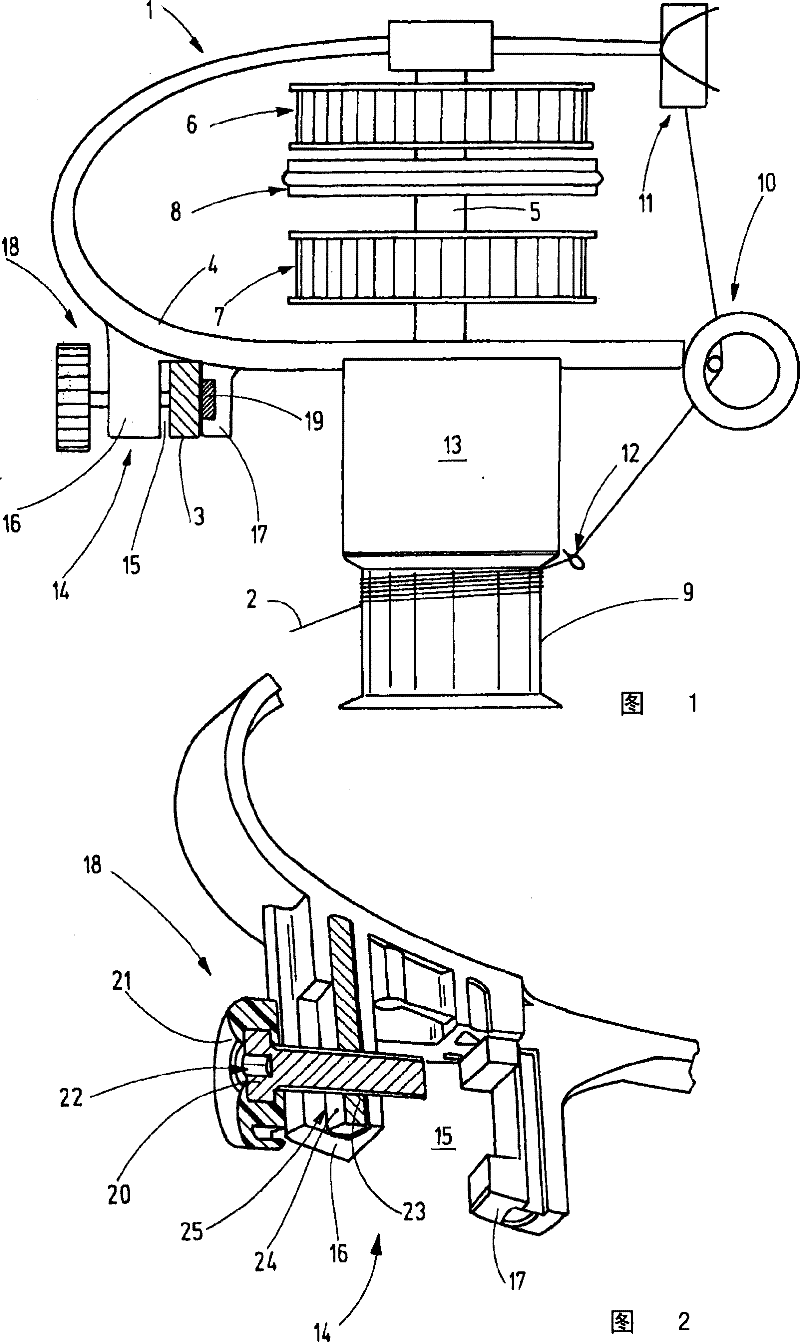

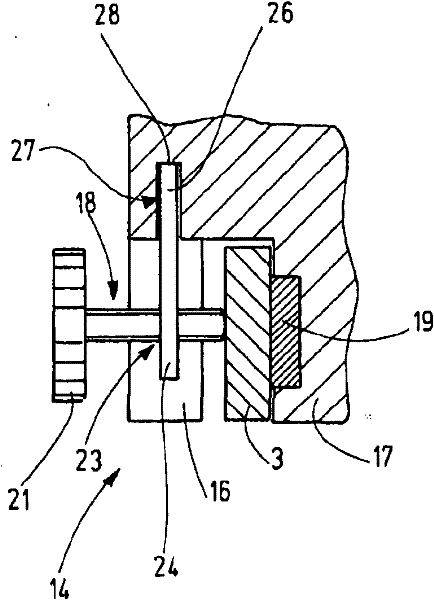

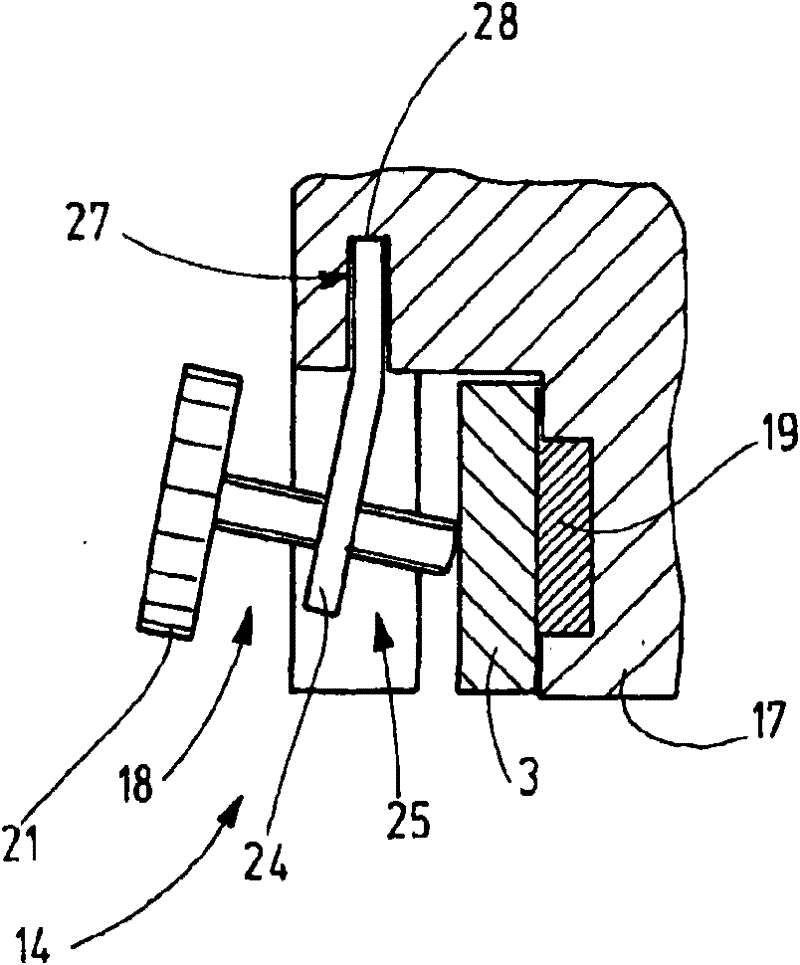

[0022] figure 1 Shown is a yarn delivery device 1 configured as a normal yarn delivery device and arranged to deliver a yarn 2 to a yarn consumption location, for example to a knitting location of a knitting machine. Typically, a plurality of such yarn delivery devices 1 are arranged on a carrier 3 of a circular knitting machine, said carrier being configured in this case as a closed ring spindle. figure 1 A vertical section of the carrier 3 is shown. The yarn delivery device 1 comprises a central holder 4 on which, for example, a vertically arranged, rotatably supported shaft 5 with pulleys 6, 7 for making one of the pulleys 6, 7 A clutch 8 in selective torque transmitting engagement with the shaft 5 and a yarn delivery wheel 9 connected to the shaft 5 at its lower end in a torque resistant manner. Additional elements can also be arranged on the holder 4, i.e. for example a yarn brake 10, a yarn guiding device 11, 12, a functional housing 13, or other not shown for example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com