Parallel-connection connected vibration reduction seat with multiple degree of freedom for automobile

A degree of freedom, parallel technology, applied in vehicle seats, seat suspension devices, vehicle components and other directions, can solve the problems of inability to meet the needs of vibration reduction, single degree of freedom for vibration reduction, etc., to achieve reliable work, easy production and processing, The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

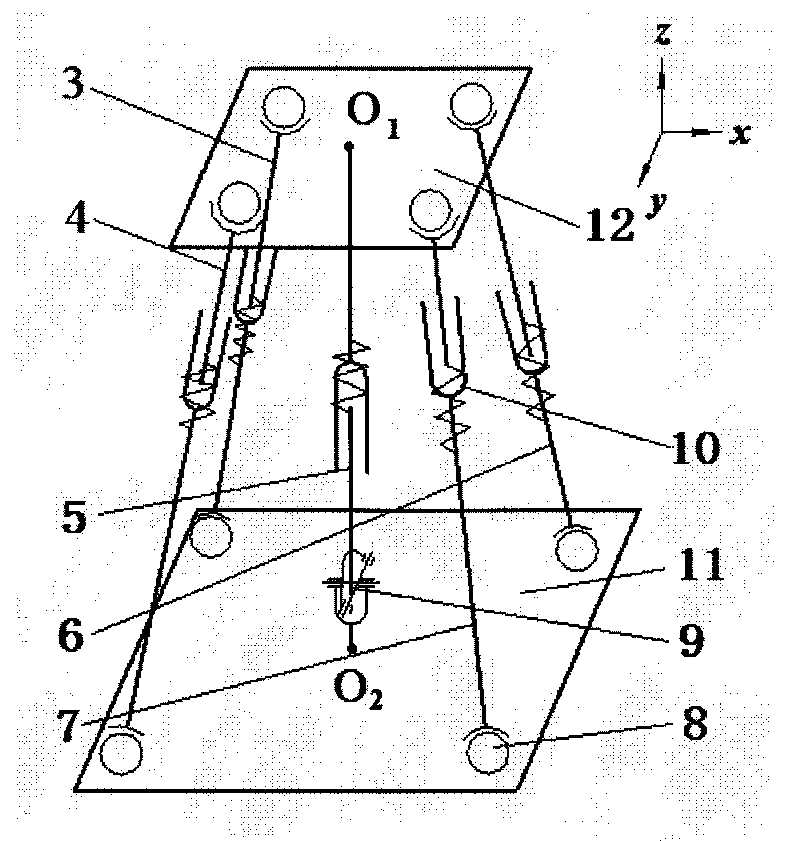

[0013] like figure 1 As shown, the seat 1 is fixedly connected to the moving platform 12 of the multi-degree-of-freedom damping structure 2, and the static platform 11 of the parallel mechanism is fixedly connected to the vehicle floor.

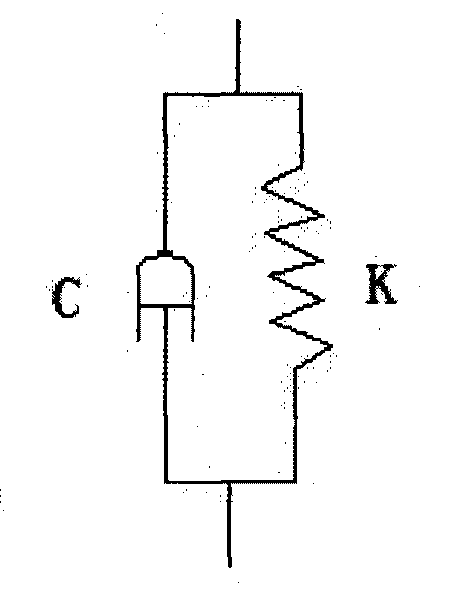

[0014] combine figure 2 , the multi-degree-of-freedom vibration damping structure 2 is a five branch chain space parallel mechanism, which is composed of four identical branch chains and a main chain 5 in parallel, and a square dynamic platform 12 and a static platform 11. The branch chain consists of a ball pair, a moving pair, The ball pairs are composed in turn, branch chain A3, branch chain B4, branch chain C6, and branch chain D7 are formed in parallel, and are arranged at the four corners between the moving platform 12 and the static platform 11; the middle one is composed of a moving pair and a Hooke hinge 9 The main chain 5, the Hooke hinge 9 are connected with the static platform 11, and one end of the moving pair is rigidly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com