Mechanical temperature control refrigerator refrigeration system capable of quickly freezing and closing cold room and control method

A technology of refrigeration system and refrigerating room, which is applied to refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high cost of control circuit, low ability to freeze food, and refrigerating room cannot be closed alone, so as to improve freezing ability and save energy. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

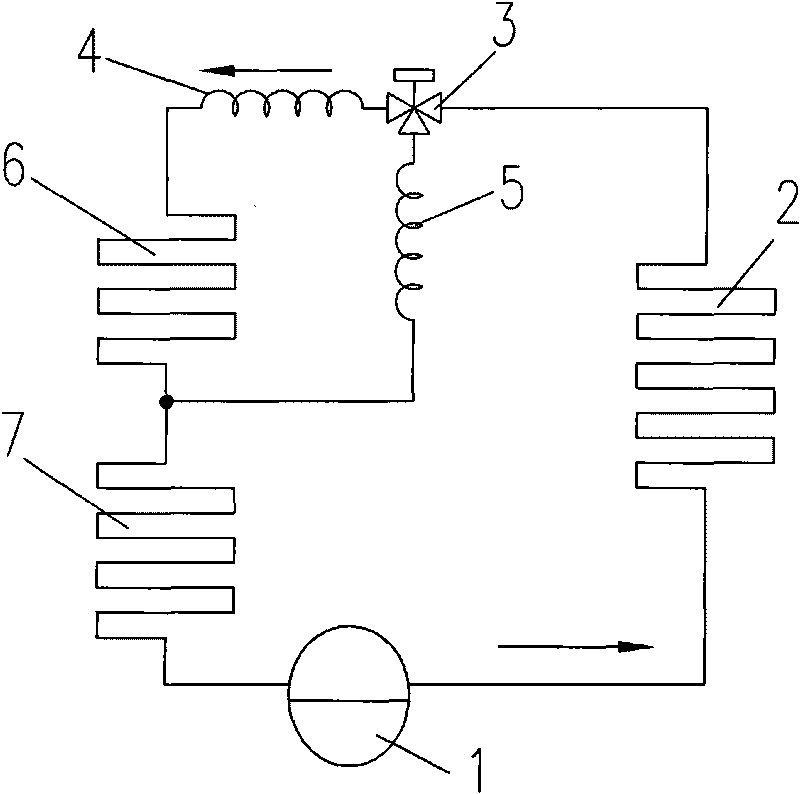

[0018] see figure 1 , in the refrigeration system composed of compressor, condenser 2, main circuit capillary tube 4, refrigeration evaporator 6 and freezing evaporator 7, between the outlet end of condenser 2 and the main circuit capillary tube 4, a bypass solenoid valve is set 3. Connect the bypass outlet of the bypass solenoid valve 3 to the inlet of the refrigeration evaporator 7 through the bypass capillary 5;

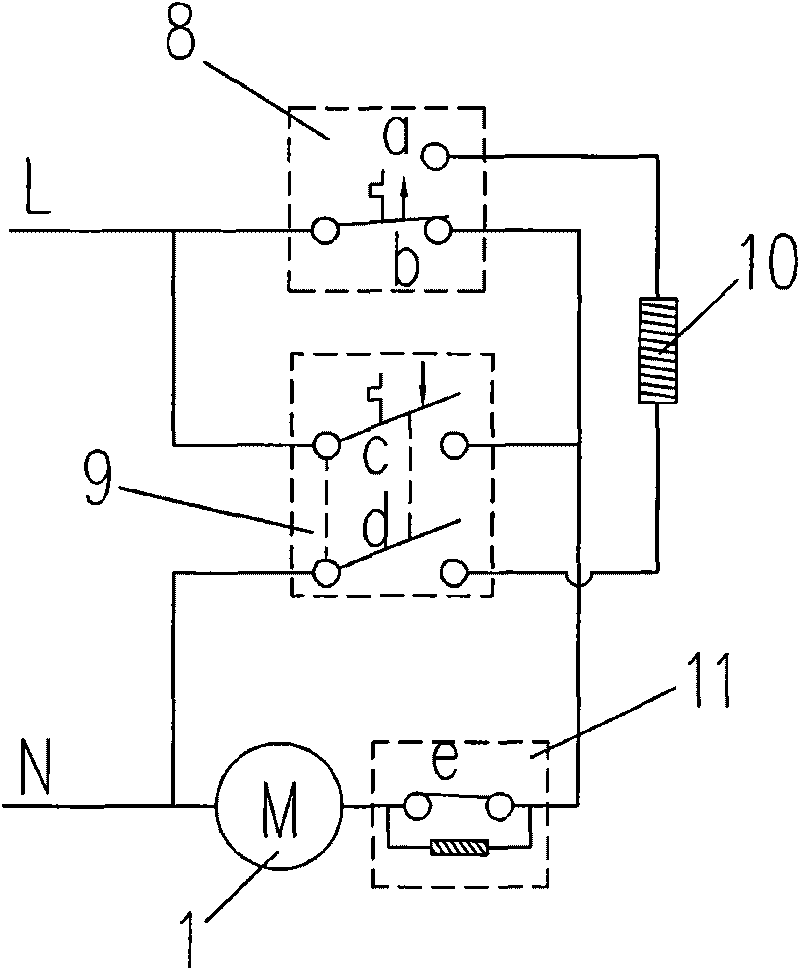

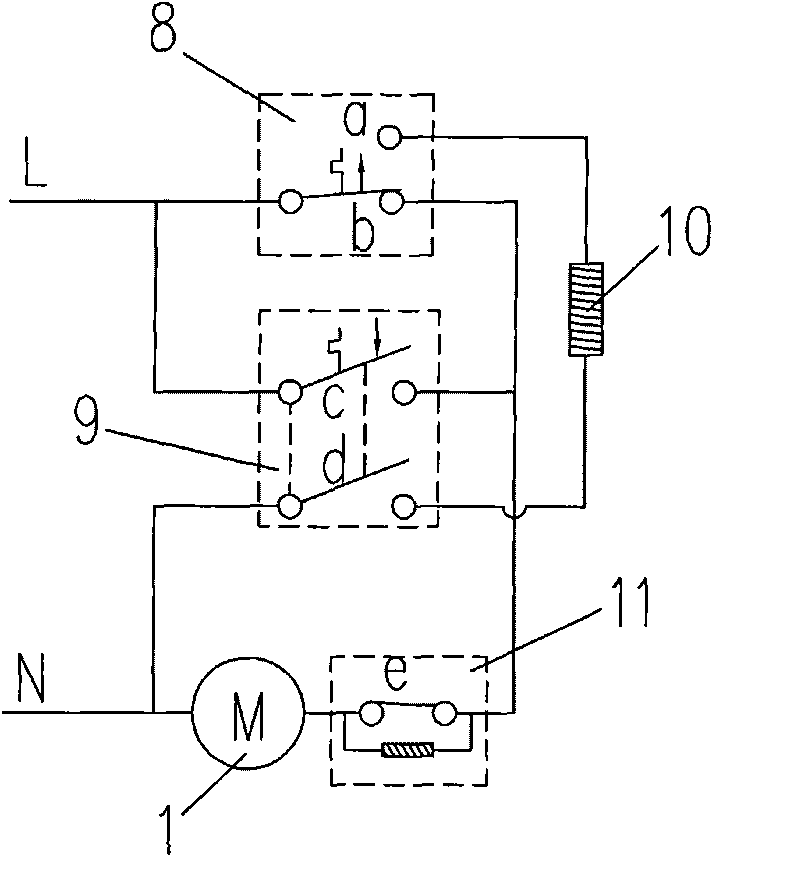

[0019] like figure 1 , figure 2 As shown, in this embodiment, a refrigerator room controller 8 and a freezer room controller 9 are respectively set; Manually controllable temperature-controlled double-pole double-throw switch; the contact a of the refrigerator room temperature controller 8 and the switch d of the freezer room temperature controller 9 are connected in series in the power circuit of the solenoid valve coil 10, and the refrigerator room temperature control The contact b of the device 8 and the switch c of the freezer temperature controller 9 are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap