Auger-type refrigerating plant

A refrigeration device and screw-type technology, which is applied in the direction of rotary piston pumps, rotary piston machinery, refrigerators, etc., can solve the problems of reduced refrigeration capacity, insufficient sealing effect, and reduced performance of screw compressors, etc., to achieve improved refrigeration capacity , the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

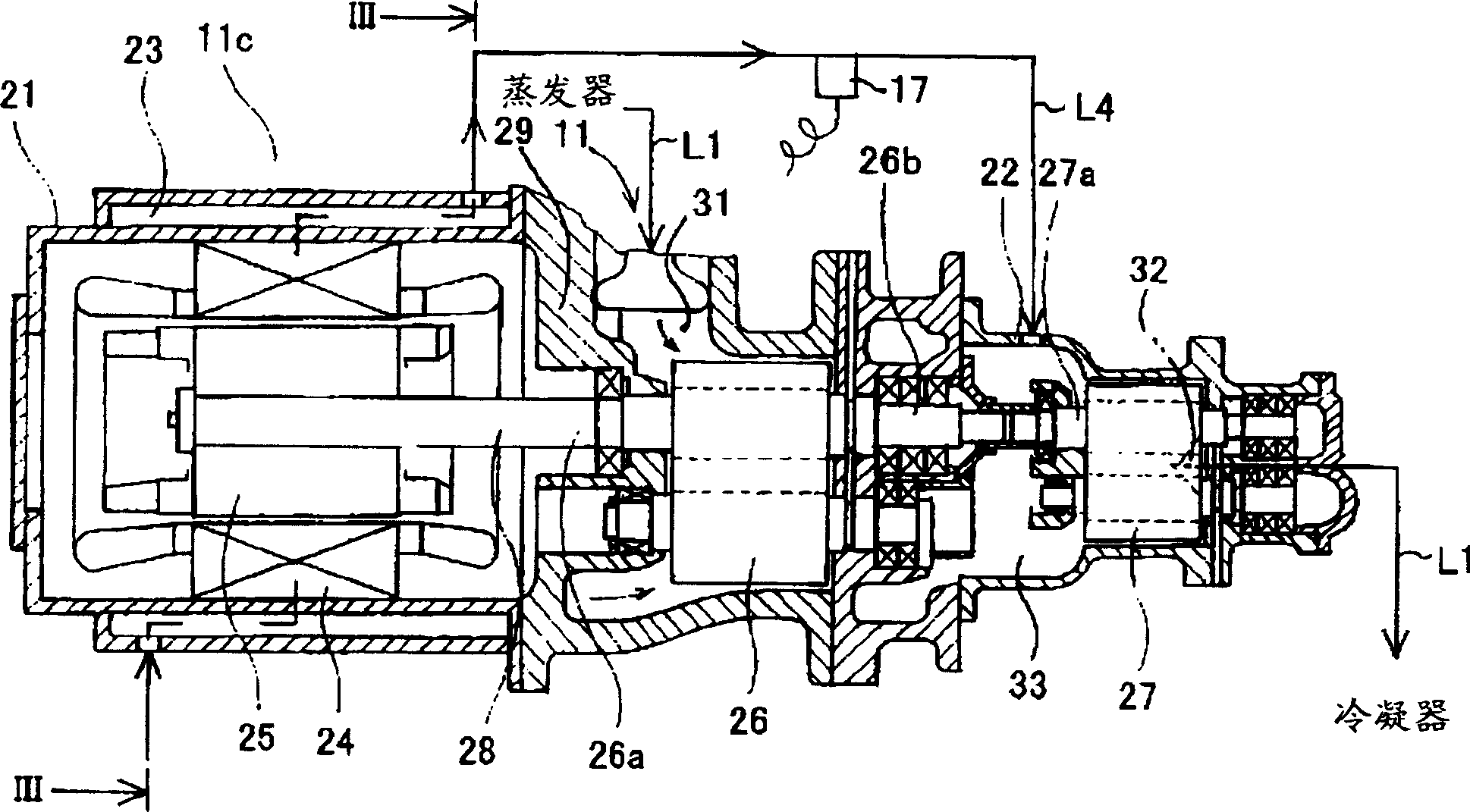

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

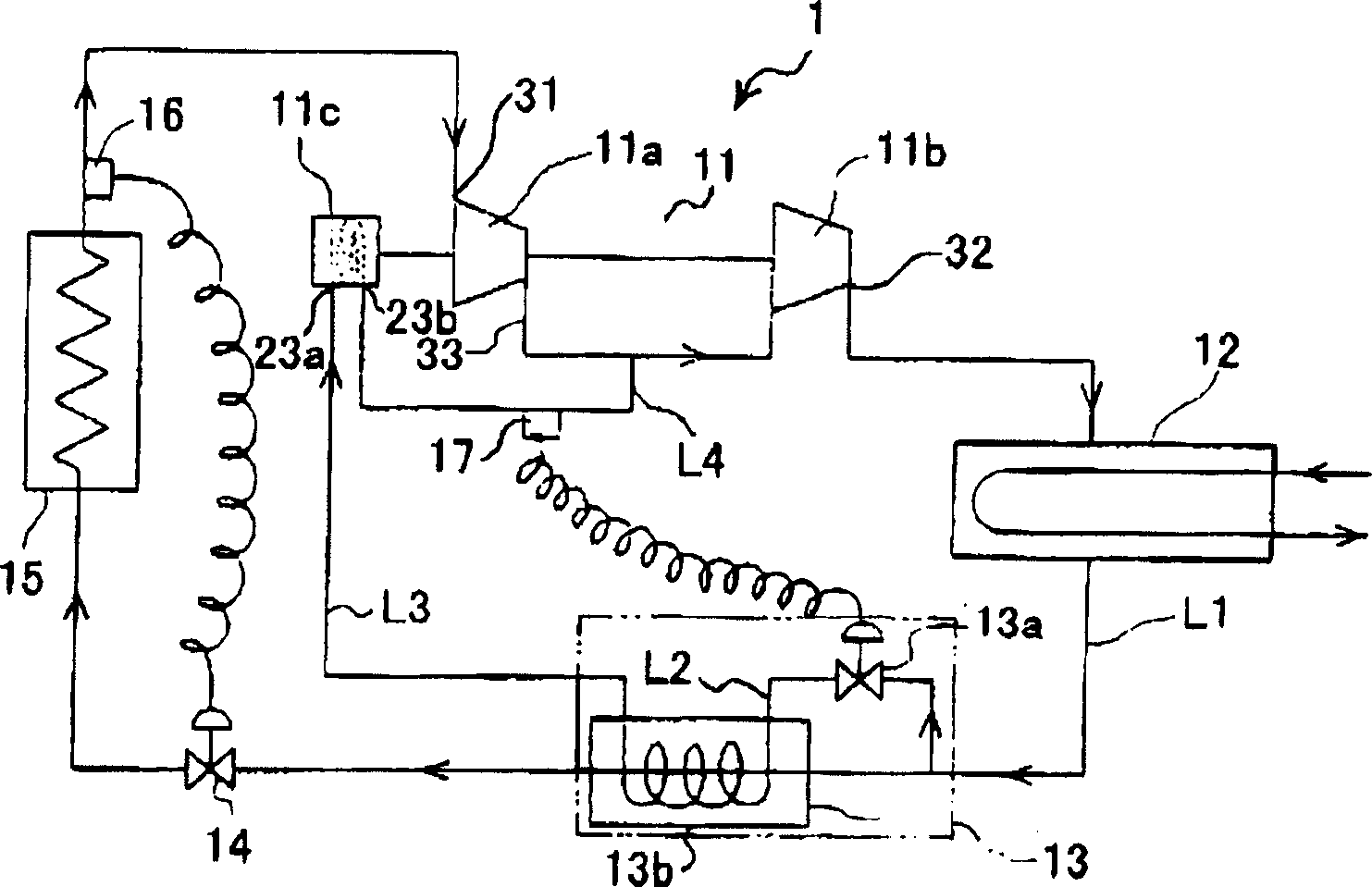

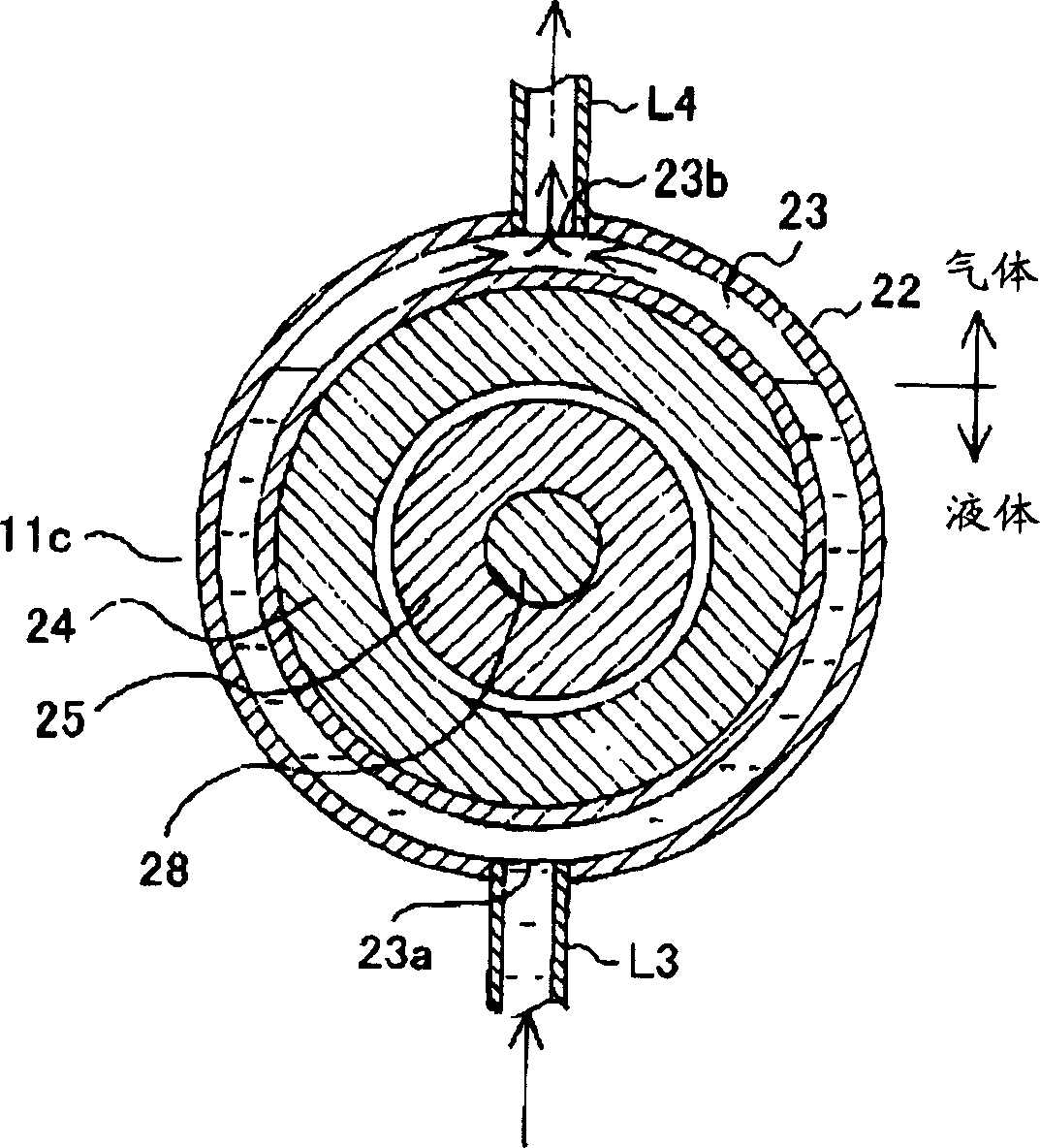

[0022] Figure 1 ~ Figure 3 The screw refrigeration device 1 showing the first embodiment of the present invention is provided with: a screw compressor 11, and the gas compression part is composed of a first-stage compressor main body 11a on the low-pressure stage side and a second compressor body 11a on the high-pressure stage side arranged in series. The stage compressor main body 11b constitutes, and a refrigerant circulation flow path L1 including a condenser 12 , an economizer 13 , a main expansion valve 14 and an evaporator 15 .

[0023] The so-called economizer is a mechanism that divides a part of the condensed and liquefied refrigerant, expands the refrigerant to the intermediate pressure between the condensation pressure and the evaporation pressure, and supercools the refrigerant.

[0024] The economizer 13 has an auxiliary expansion valve 13a and a heat exc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap