High-viscosity fluid filtering device with backwashing function

A filter device and high-viscosity technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of low pressure resistance, waste of time, high maintenance costs, etc., and achieve long service life and not easy to damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

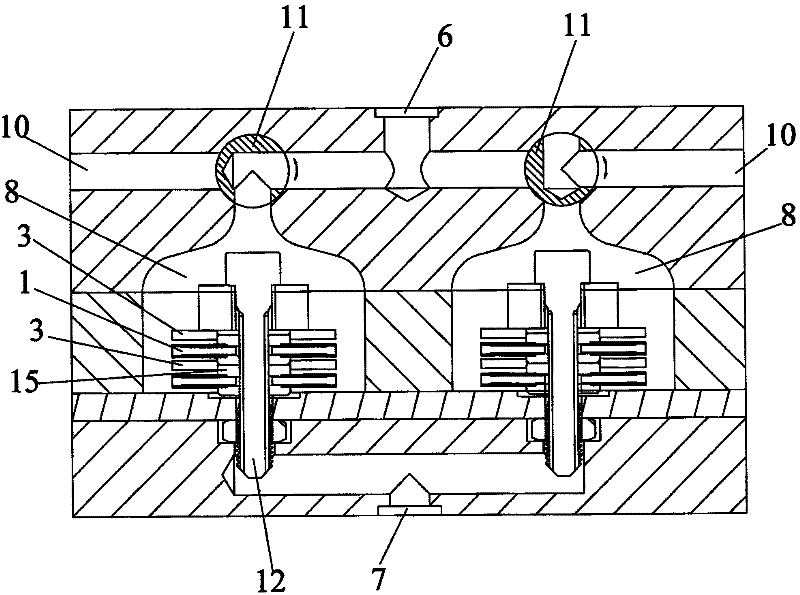

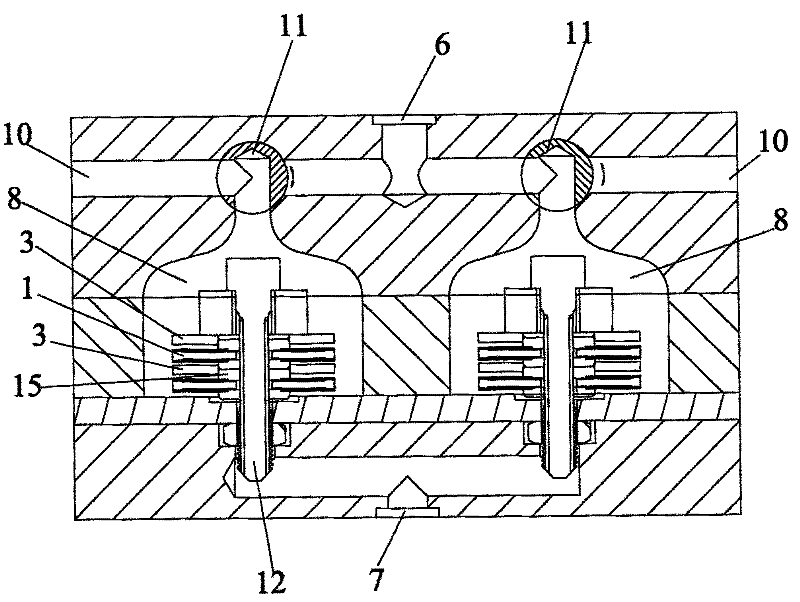

[0021] Example: such as figure 1 and figure 2 Shown, a kind of high-viscosity fluid filtering device with backwashing function comprises feed inlet 6, feed outlet 7 and filter chamber 8 between feed inlet 6 and discharge outlet 7, and described filter chamber 8 is provided with There is a filter core, and the filter is also provided with a discharge port 10, and the filter chamber 8 includes at least two, and a switching valve 11 is provided between the inlet of each filter chamber 8 and the feed port 6 and the discharge port 10 , the outlets of the at least two filter chambers 8 communicate with each other and communicate with the outlet 7 at the same time.

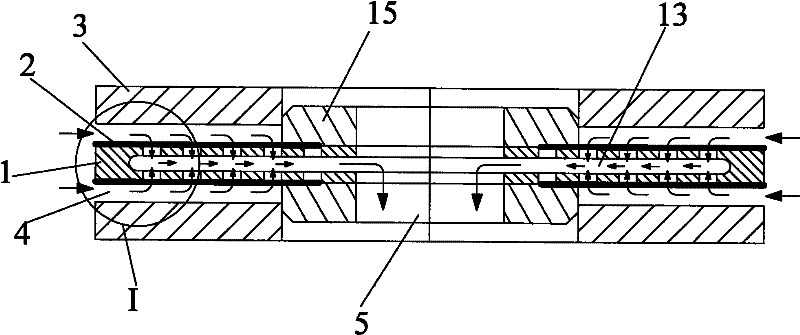

[0022] The filter core includes a support body 1 with a filter hole 9 and a filter screen 2 covering the filter hole 9 on the outside of the support body 1. The inside of the support body 1 is a hollow structure with a flow channel 13. Specifically, the support body 1 The cross section of the U-shape is U-shaped, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com