Filter element for filtering high-viscosity fluid

A high-viscosity, filter element technology, used in filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of high maintenance cost, waste of time, low pressure resistance, etc., to achieve low maintenance cost, not easy to damage, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

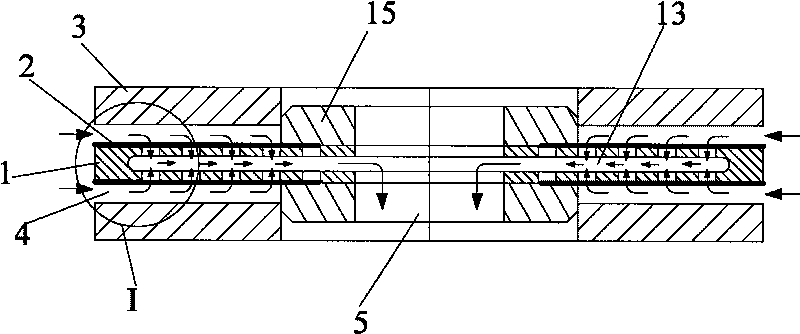

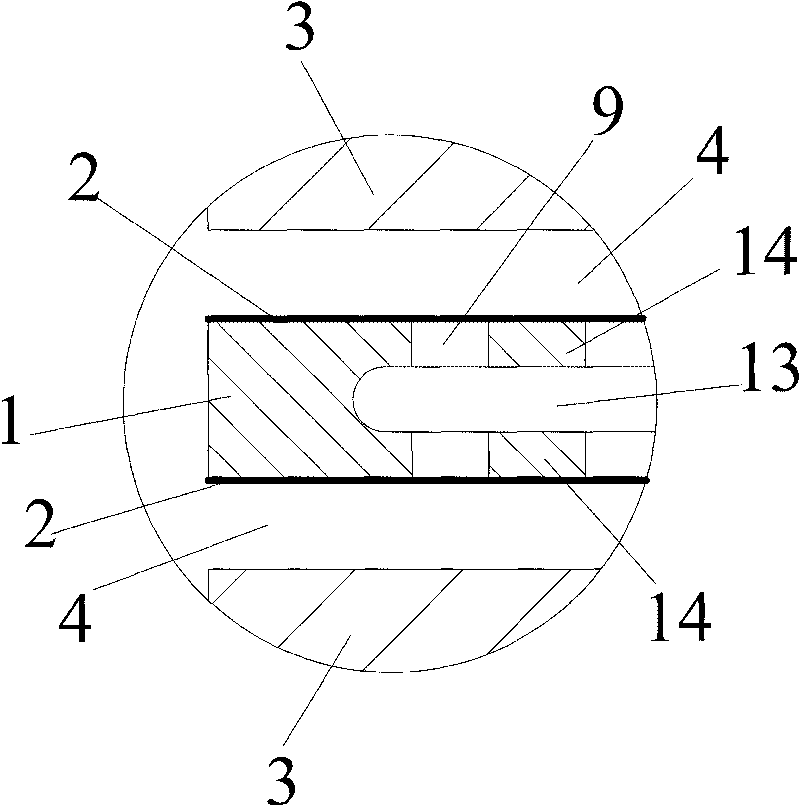

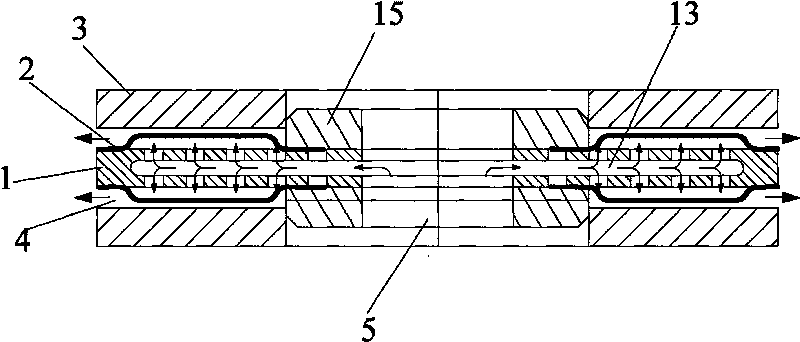

[0017] Example: such as Figure 1 to Figure 3 As shown, a filter element for high-viscosity fluid filtration includes a support body 1 with a filter hole 9 and a filter screen 2 covering the filter hole 9 on the outside of the support body 1, and the inside of the support body 1 has a flow channel 13 The hollow structure, specifically, the cross section of the support body 1 is U-shaped, the hollow part of the U-shape is the flow channel 13, and the two sides of the U-shape are the support body walls 14, and the flow channel 13 passes through the U-shaped opening part and the The filter element discharge port 5 is connected, and the filter hole 9 is arranged on the support wall 14 on both sides, and the filter screen 2 is respectively covered on the outside of the two support body walls 14, and the filter screen 2 on the two sides is also A protector 3 is provided respectively, and the side of the protector 3 facing the filter screen 2 is arranged parallel to the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com