Sucker rod anti-tripping connecting device and manufacturing method thereof

A connecting device and anti-tripping technology, which is applied in the direction of manufacturing tools, drill pipes, earthwork drilling, etc., can solve problems such as sucker rod tripping and inability to overcome the shackle torque, so as to reduce tripping and improve drilling efficiency The effect of high and enhanced shackle torque capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

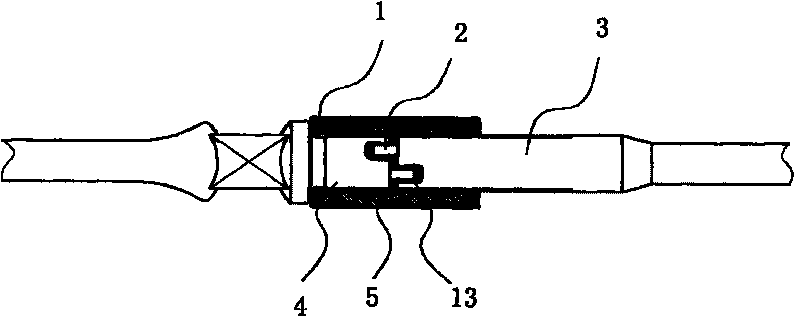

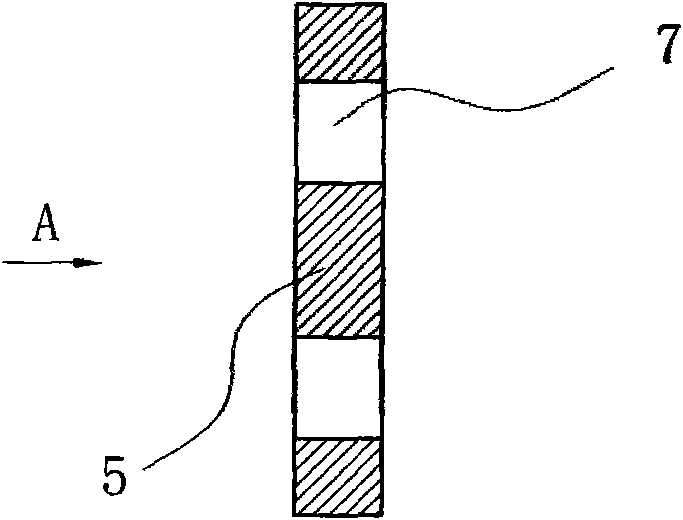

[0021] Such as figure 1 , image 3 and Figure 4 As shown, the sucker rod anti-trip connection device includes a rod body, and the two ends of the rod body are respectively provided with a main connection end 4 and a slave connection end 3, and the main connection end 4 and the slave connection end of the adjacent rod body 3 is provided with a connection device, the connection device includes blind holes 13 respectively arranged on the main connection end 4 and the end surface of the slave connection end 3, the blind hole 13 is eccentrically arranged on the end surface, in the Blind hole 13 is inserted with anti-off shaft 2, and the other end of described anti-off shaft 2 is fixed on the through hole 7 that offers on connecting plate 5, and described main connecting end 4 and the connecting part thread that forms from connecting end 3 Connected with collar 1.

[0022] Such as Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the method of manufacturing the sucke...

Embodiment 2

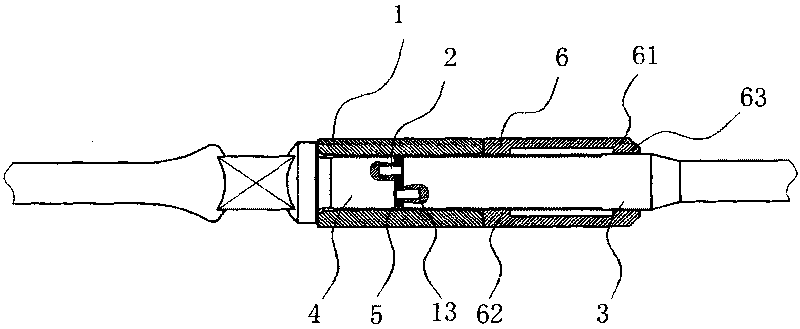

[0024] Such as figure 2 and Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a locking anti-bending joint 6 is threaded on the slave connection end 3, and the locking and anti-bending joint 6 is axially compressed The collar 1. The two ends of the locking anti-bending joint are respectively a locking end 62 and an anti-bending end 61. Internal threads are provided on the locking end 62, and protrusions 63 are provided on the inner surface of the anti-bending end 61. The protrusion 63 is closely attached to the outer surface of the slave connection end 3 .

[0025] Such as Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the method of manufacturing the sucker rod anti-trip connection device: tighten the special drilling die on one end of the blank 11 of the rod body, and make the positioning surface 12 of the disc on the special drilling die close to the blank 11 The end surface of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com