Coffee machine

A technology for coffee machines and heat pipes, applied in beverage preparation devices, home appliances, applications, etc., can solve problems such as wasting energy and not meeting environmental protection requirements, and achieve the effect of energy saving and effective use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

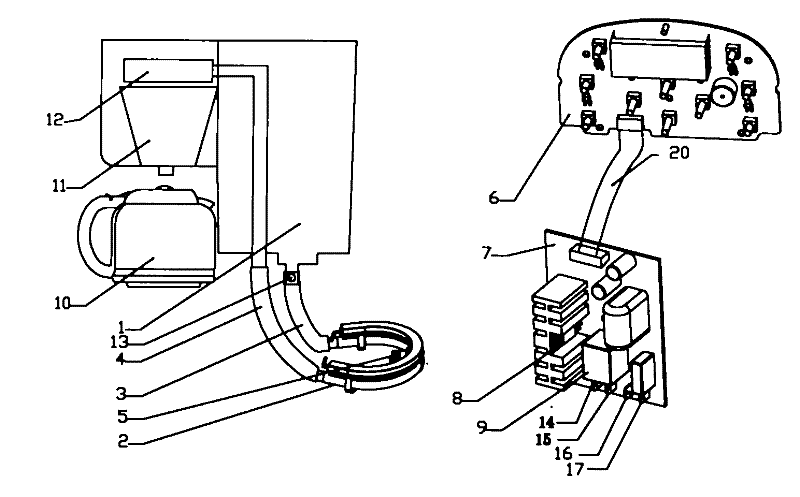

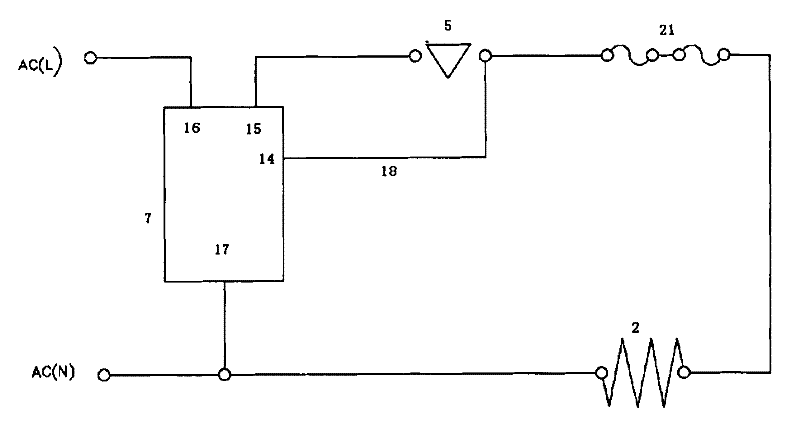

[0022] Such as figure 1 , 2 As shown, the coffee machine according to the present invention includes a water tank 1, and the water tank 1 is connected to one end of the heating pipe 2 through the one-way valve 13 and the water inlet pipe 3 in turn.

[0023] The other end of the heating pipe 2 is connected to the hot water outlet 12 of the coffee machine through the water outlet pipe 4,

[0024] The lower end of the hot water outlet 12 is a shower head, and directly below it is a filter trough 11 for holding coffee powder. The coffee cup 10 is placed directly under the filter trough 11 to hold the brewed coffee. The whole process of brewing coffee until Until the water in the water tank 1 runs out,

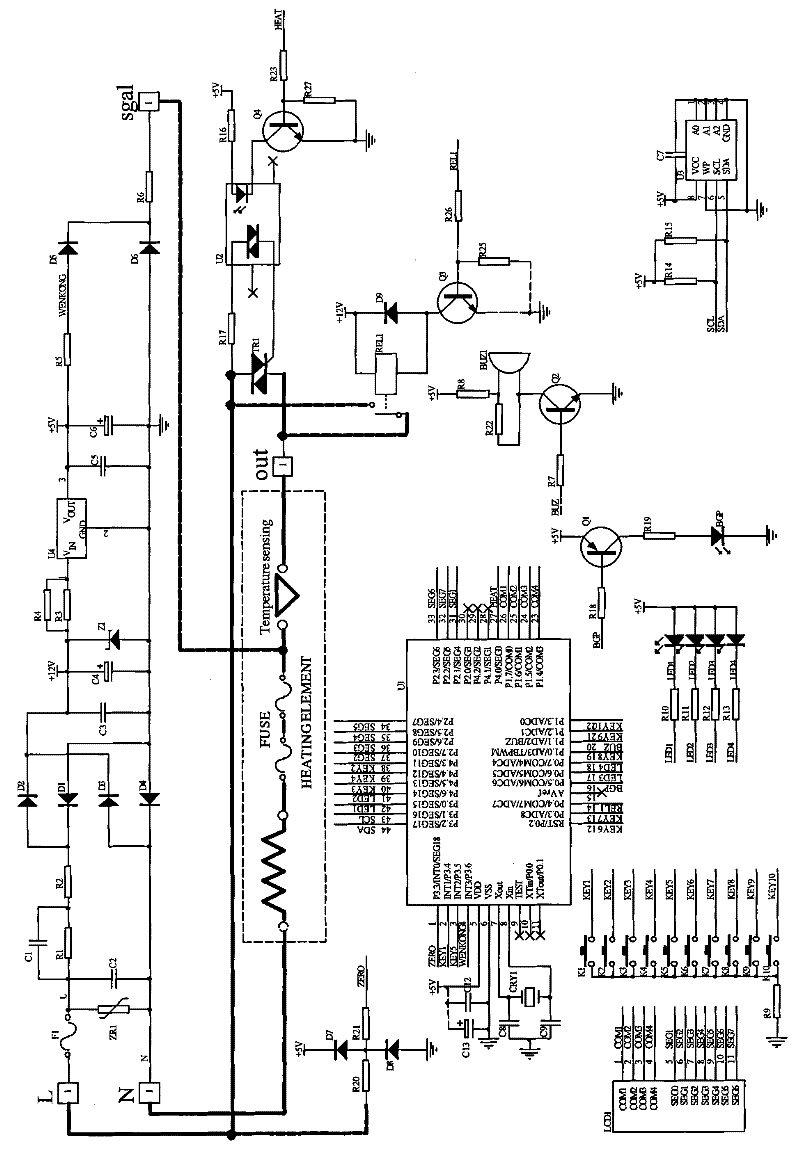

[0025] The PCB control board 6 is connected with the power circuit board 7 through the data line 20,

[0026] The heat pipe 2 is provided with a thermostat 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com