Variable inertial mass hydraulic damper

A hydraulic shock absorber and inertial mass technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of dissipating energy and wasting power, and achieve low calorific value, saving power energy, The effect of excellent vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

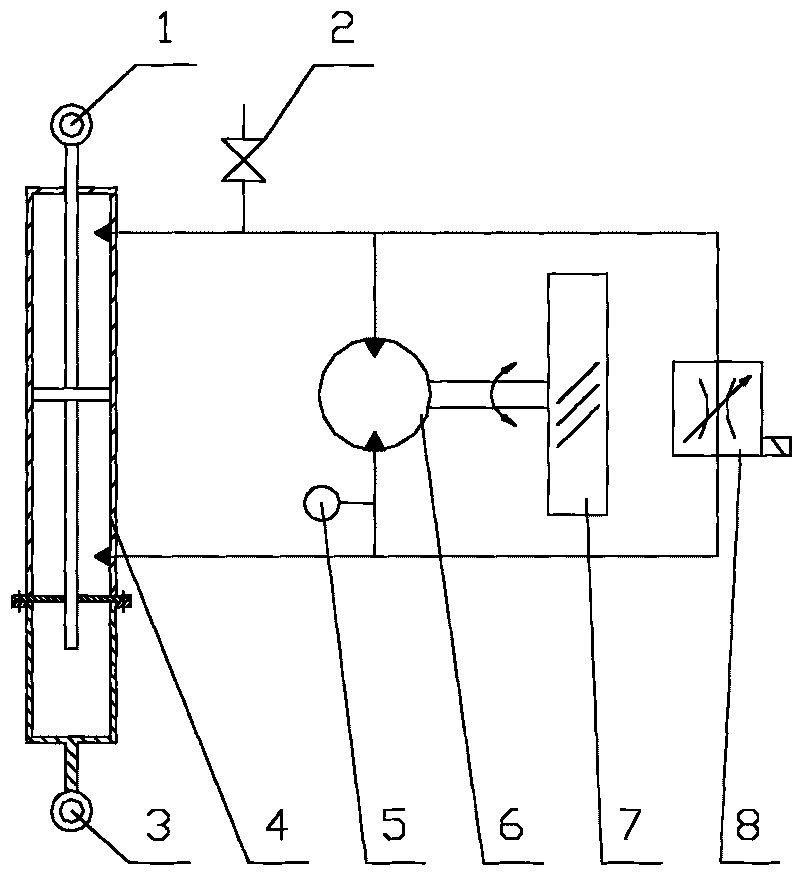

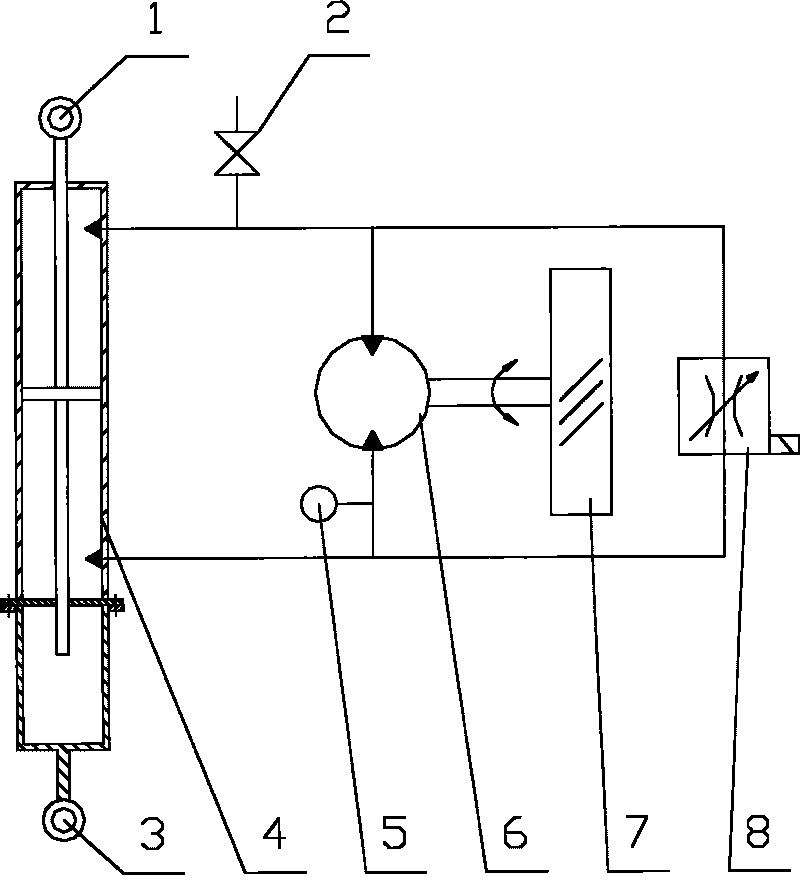

[0021] Such as figure 1 In the shown embodiment, the hydraulic shock absorber with variable inertial mass is mainly composed of a first vibration acting end 1, a valve 2, a second vibration acting end 3, a hydraulic cylinder 4, a flow meter 5, a hydraulic motor 6, a flywheel 7 and an electric shock absorber. Liquid regulating valve 8 and other components. Due to the utilization of the amplification effect of the hydraulic transmission composed of the hydraulic cylinder and the hydraulic motor, when the electro-hydraulic regulating valve is closed, the present invention can obtain a maximum magnification of the actual mass of the flywheel by 2π 2 S 2 r 2 / n 2 times the equivalent inertial mass, so a larger inertial mass of the shock absorber can be achieved with a smaller mass flywheel.

[0022] The electro-hydraulic regulating valve in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com