Cylindrical fabric knitting method, and cylindrical fabric

A knitwear and weaving cylinder technology, which is applied in the knitting of tubular knitwear and the field of tubular knitwear, can solve problems such as roughness, and achieve the effect of reducing the risk of thread breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

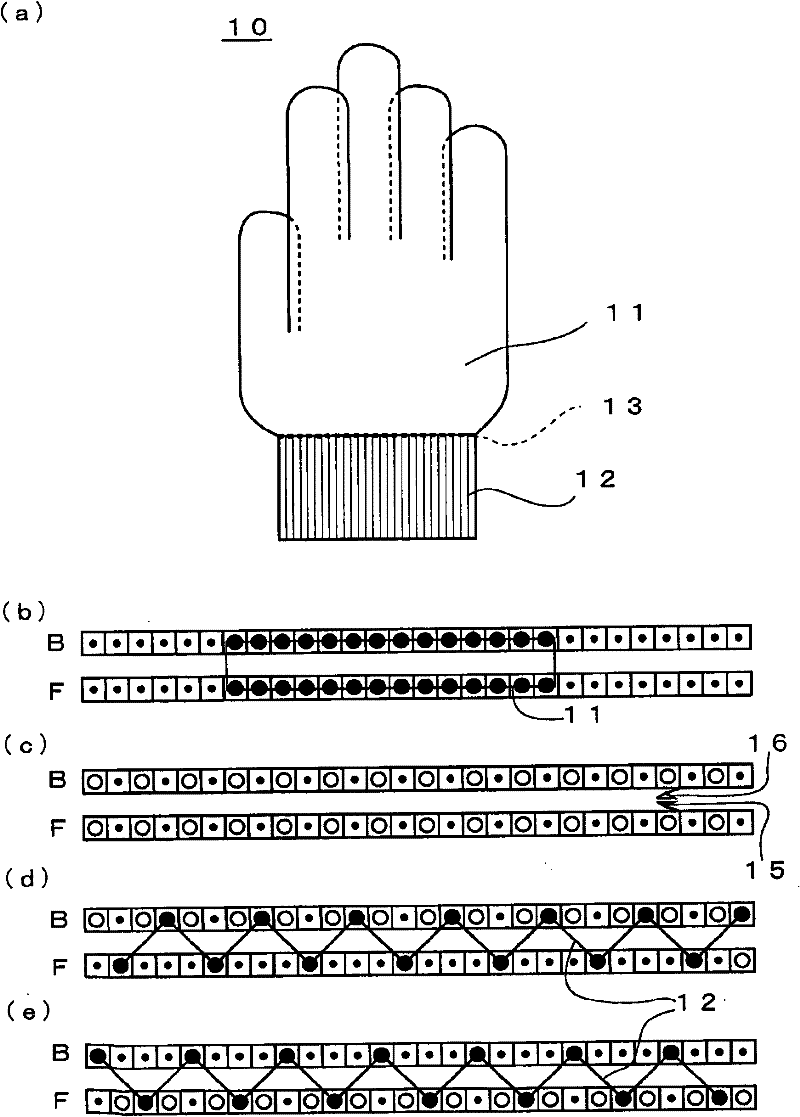

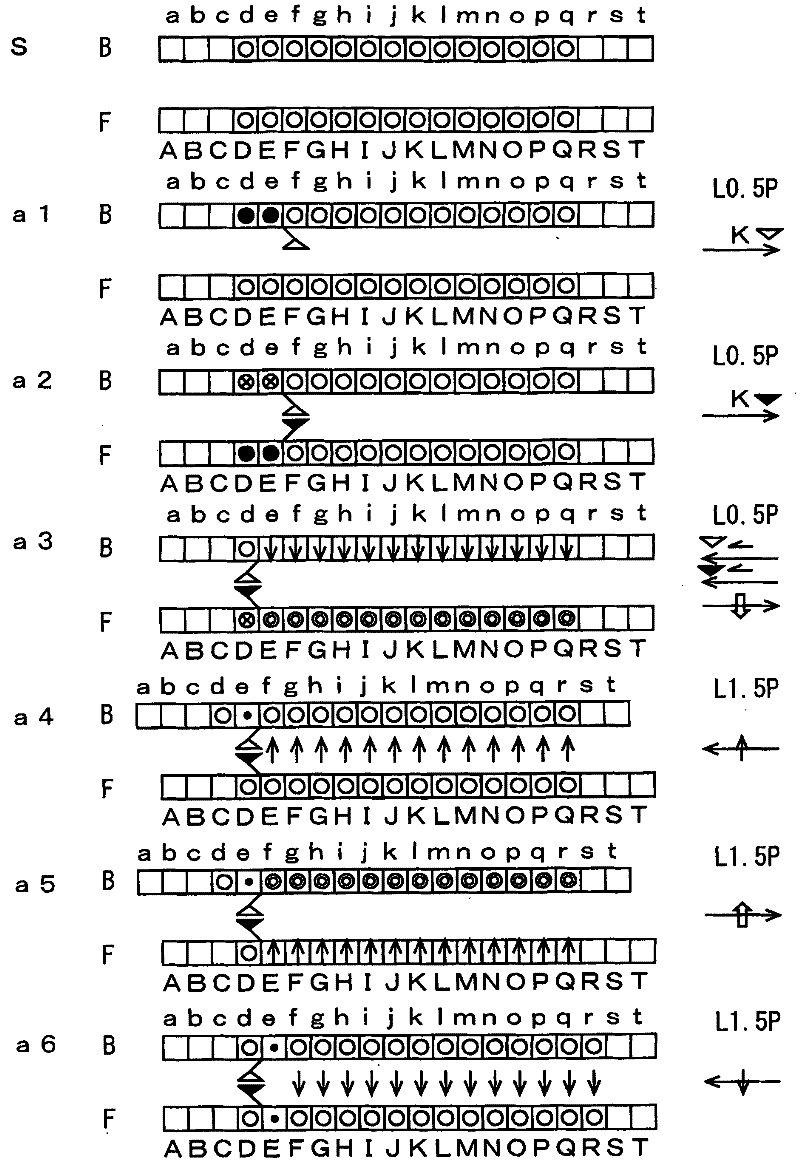

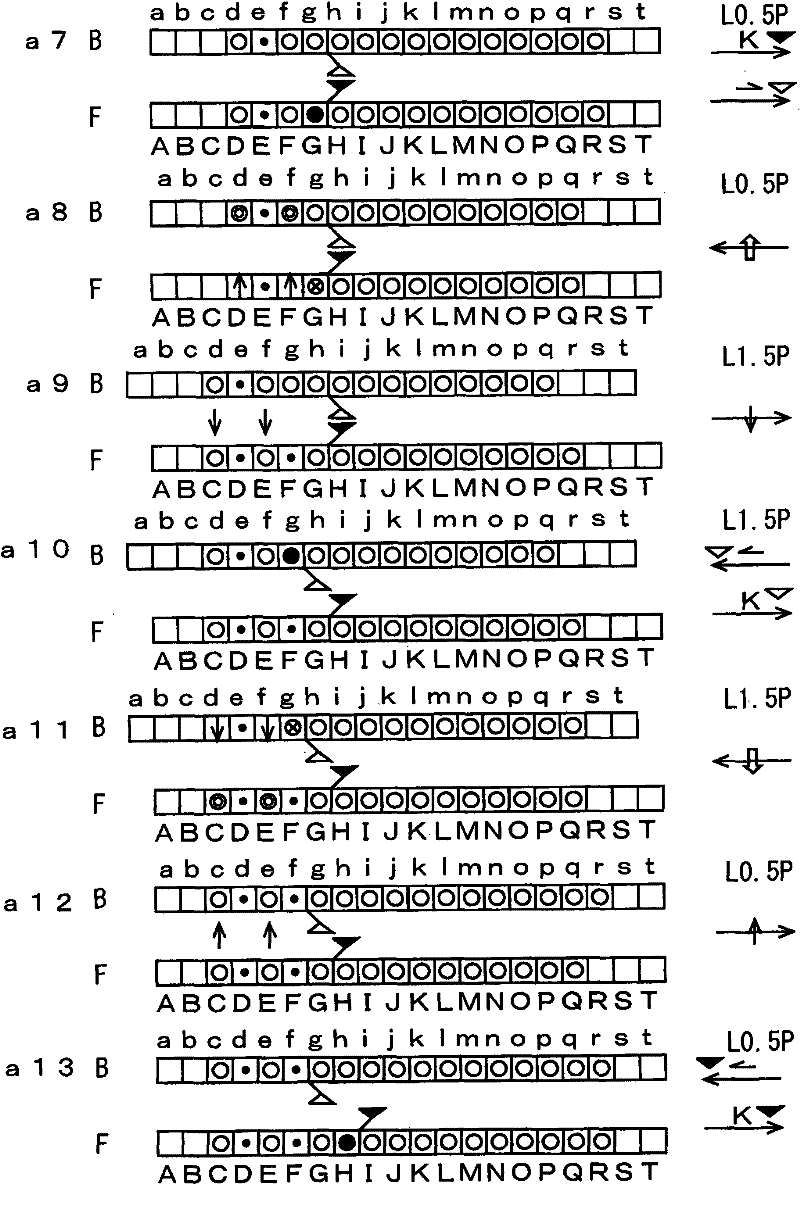

[0040] figure 1 The schematic structure of the glove 10 knitable by the knitting method of the tubular knitted fabric according to one embodiment of the present invention and the knitting state on the front and rear needle beds are shown. In addition, in each of the following figures, the front needle bed and the rear needle bed are denoted by F and B, respectively. In addition, squares in each needle bed represent knitting needles. The dots in the squares represent empty needles. If there is a circle in the box, it means that the coil is locked. Black circles represent newly formed loops of knitwear or the like. The triangle outside the box indicates the wire feeding port.

[0041] have figure 1 The glove 10 having the appearance structure shown in (a) is knitted into a tubular knitted fabric using a flatbed knitting machine equipped with a pair of front and rear needle beds facing each other across a needle bed. In this type of flat knitting machine, stitching and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com