Atmospheric environment comprehensive natural acceleration test system

An atmospheric environment and accelerated test technology, which is applied in the field of test systems, can solve the problems of no remote monitoring system, accelerated corrosion test, and reduce accelerated corrosion, so as to improve acceleration magnification and correlation, strengthen corrosion severity, and uniform test data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

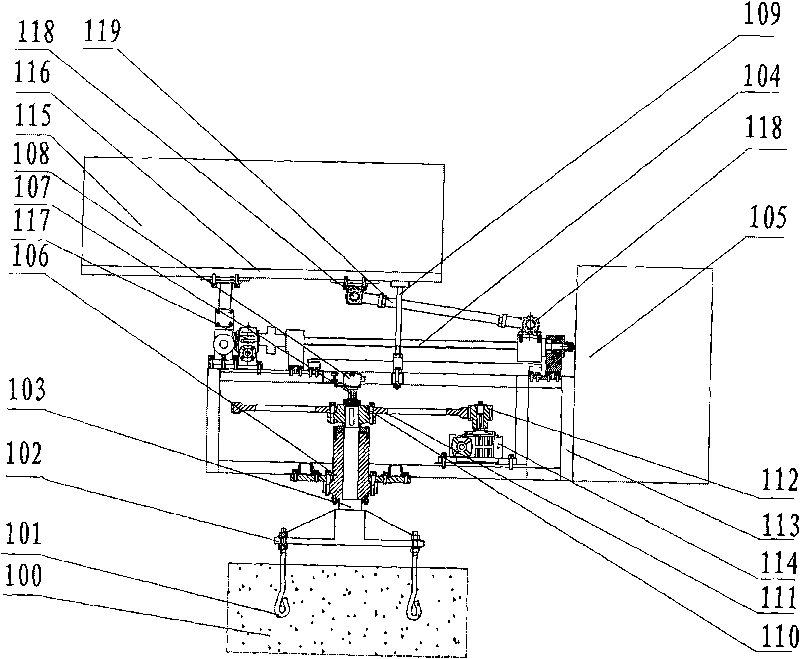

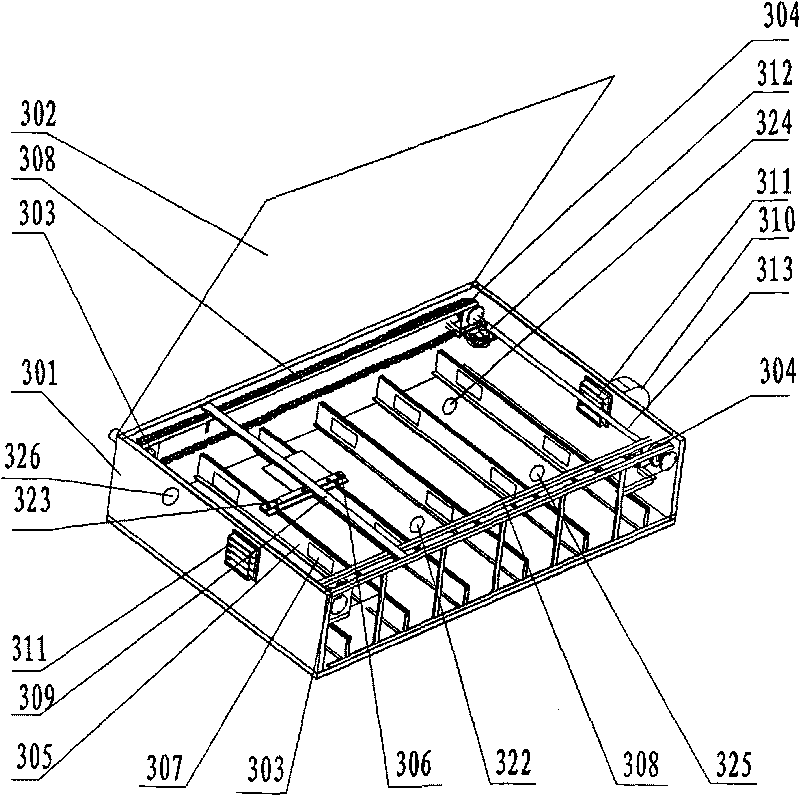

[0034] A comprehensive natural acceleration test system for atmospheric environment, including a test box 115, the test box 115 includes a box body 301 and a transparent cover plate 302 hinged on the box body, the test box is placed on the sun tracking system for tracking the sun track .

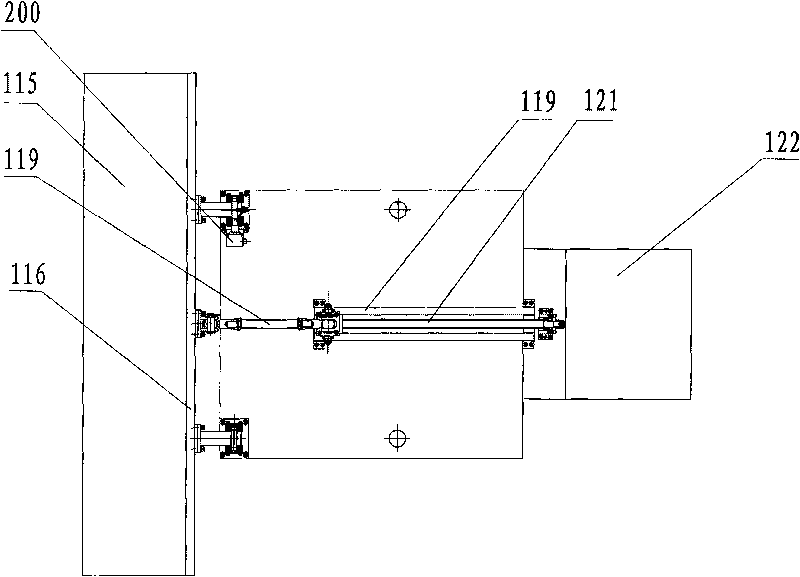

[0035] The sun tracking system is used to track the sun's altitude changes and azimuth changes. The sun tracking system tracks the azimuth and altitude of the sun at the same time by using the solar point trajectory equation, so that the surface of the flat test sample (the test surface of the test chamber) is always kept perpendicular to the sunlight, so that the sample can receive sunlight to the maximum extent. The sun tracking system includes a horizontal tracking device for horizontal rotation and a pitch tracking device for pitching movement;

[0036] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com