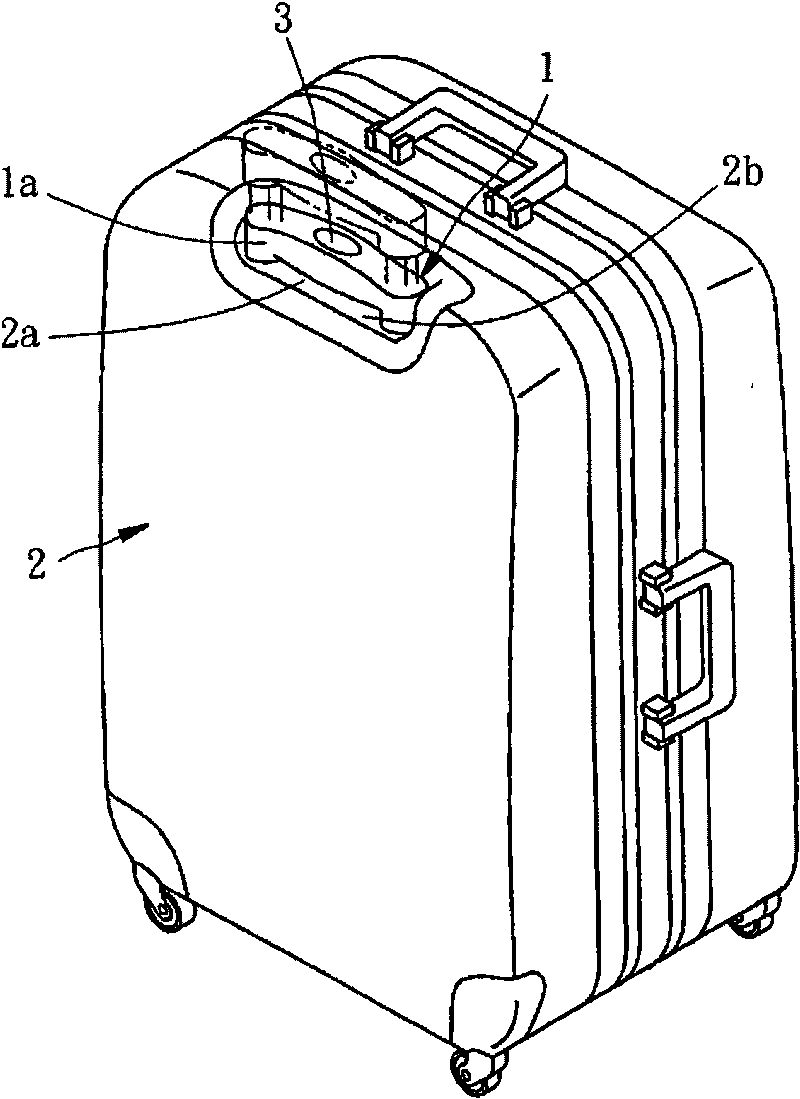

Protective structure of trunk draw bar with bouncing function

A technology for protective structures and luggage, which is applied in the field of luggage, and can solve problems such as increased gaps, exposed use of telescopic pull rods 1, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is used for the protective structure of the pull rod of the luggage case with the function of bouncing up. The pull rod is used as a suitcase controlled by the button as the bouncing up control. The spring of the pop-up structure pushes the pull rod to make it bounce up to a predetermined height, and it is convenient for the user to hold the handle on the top of the pull rod so as to pull out the pull rod for use. This will not go into details, what is relevant to the present invention is the button, hereby narrate the relationship between the button and the pull bar protective structure of the present invention as follows:

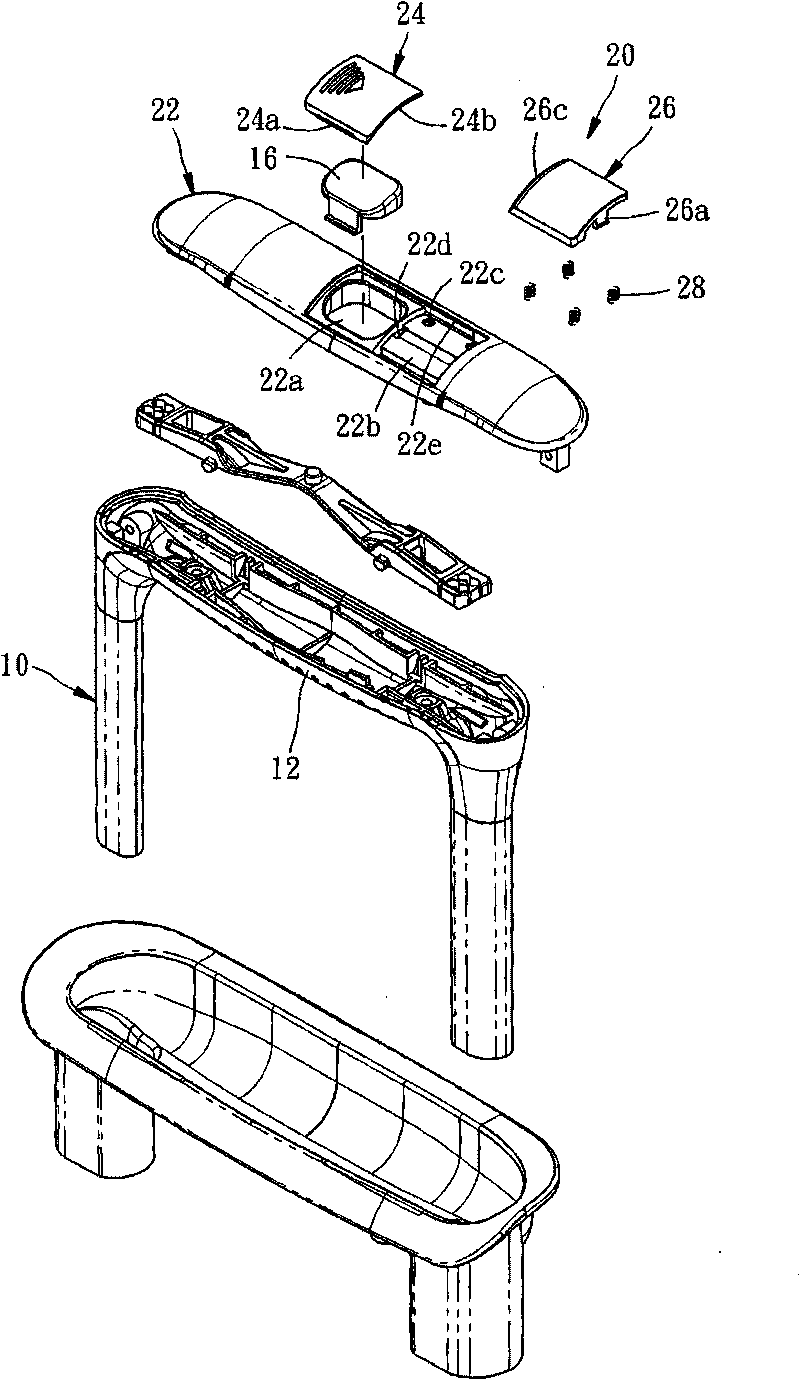

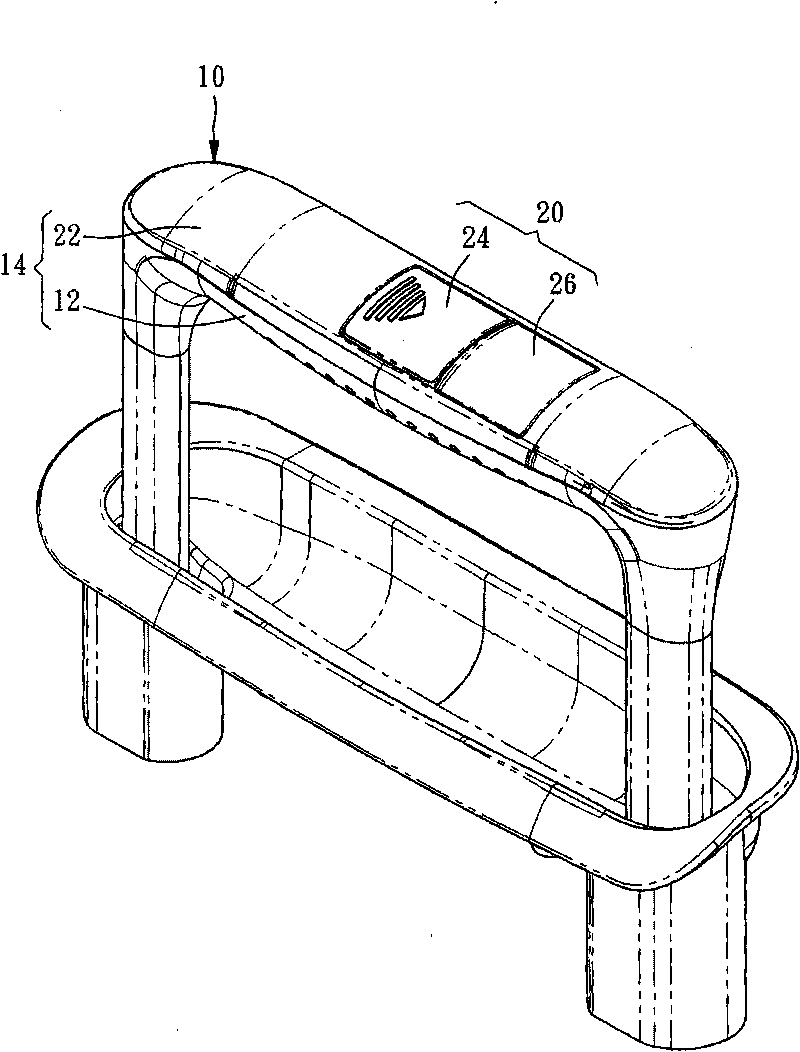

[0037] Figure 2 to Figure 4 Shown is a protective structure for a luggage trolley with a pop-up function according to a preferred embodiment of the present invention. The trolley protective structure 20 has the function of preventing the trolley 10 from automatically bouncing up without warning when it is not controlled. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com