Fruit classifier

A classifier and fruit technology, applied in sorting and other directions, can solve the problems of clogging of sieve holes, high fruit damage rate, and poor classification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

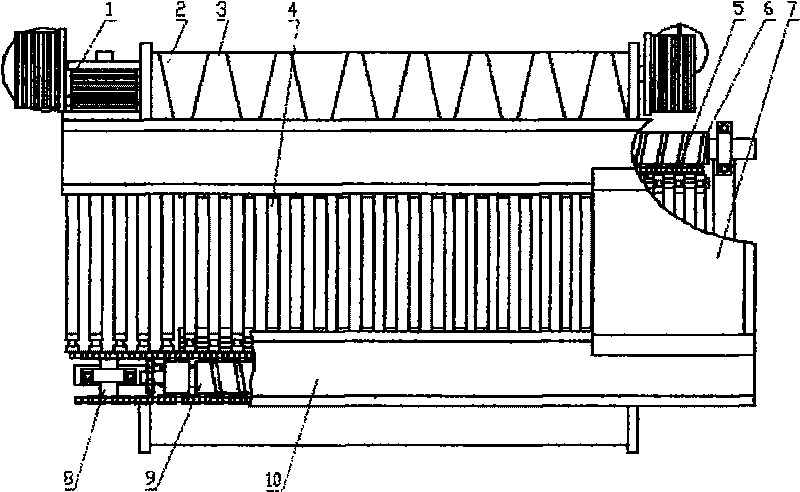

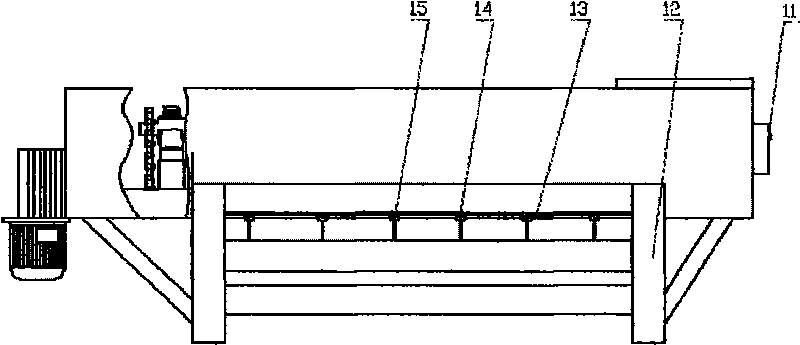

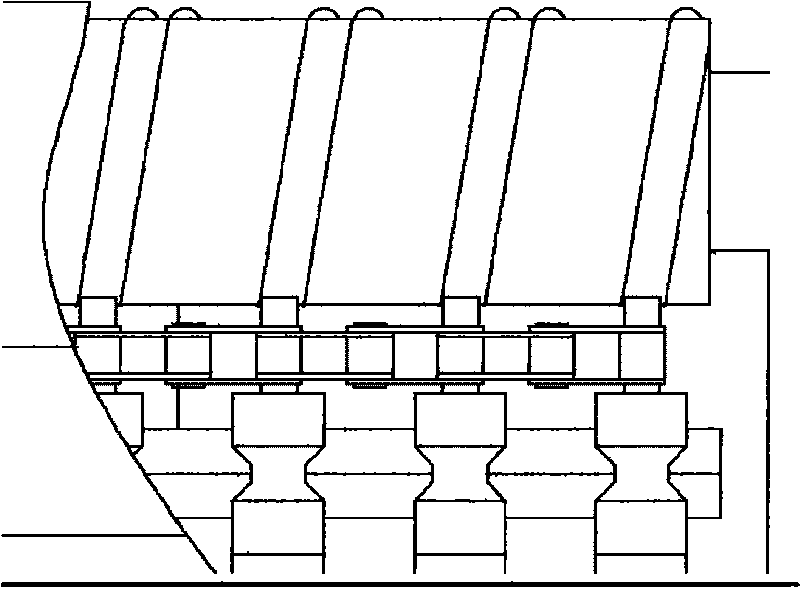

[0009] Legend: 1-speed motor; 2-conveyor belt; 3-outlet; 4-roller; 5-friction wheel; 6-track; 7-into the hopper; 8-drive shaft II; 9-drive shaft I; 10-protective cover; 11-power control switch; 12-body; 13-sliding lever; 14-adjusting nut; 15-partition;

[0010] Before grading, check whether the classifier is stuck by jogging the power control switch (11), and add materials after idling for a period of time. The power of the motor is transmitted to the transmission shaft I (9) and the transmission shaft II (8) by the chain, the transmission shaft I (9) drives the track (6) to rotate, and the transmission shaft II (8) drives the roller bar (4) on the track (6) During the middle movement, the synchronous rotation of the two transmission shafts jointly completes the variation of the roller gap, and the roller (4) slides in the spiral track (6) by means of the friction wheel (5). When the fruit enters the classifier from the hopper (7), the dried and fresh fruit whose external dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com