Auxiliary positioning and pre-locking mechanism used for clamping parts in metal cutting

A technology for assisting positioning and clamping parts, which is used in metal processing mechanical parts, positioning devices, metal processing equipment, etc., to achieve the effects of improving productivity and quality, short clamping time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

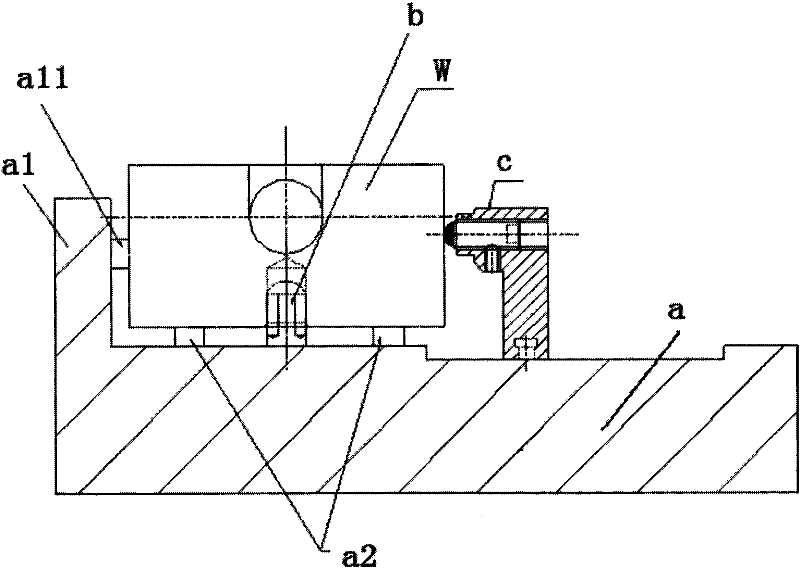

[0021] The invention provides an auxiliary positioning and pre-locking mechanism for clamping parts during metal cutting ( Figure 6-10 ), which includes an auxiliary positioning spring 3. When in use, first determine the size of the workpiece to be processed, then process two M4 threaded bottom holes on the base 1, and then assemble the auxiliary positioning spring piece 3 with the base 1 with M4 screws. The specific position and strength can be determined by the spring pad The positioning slot 32 on the sheet is adjusted (preferably using a long slot).

[0022] The following is an example of part processing:

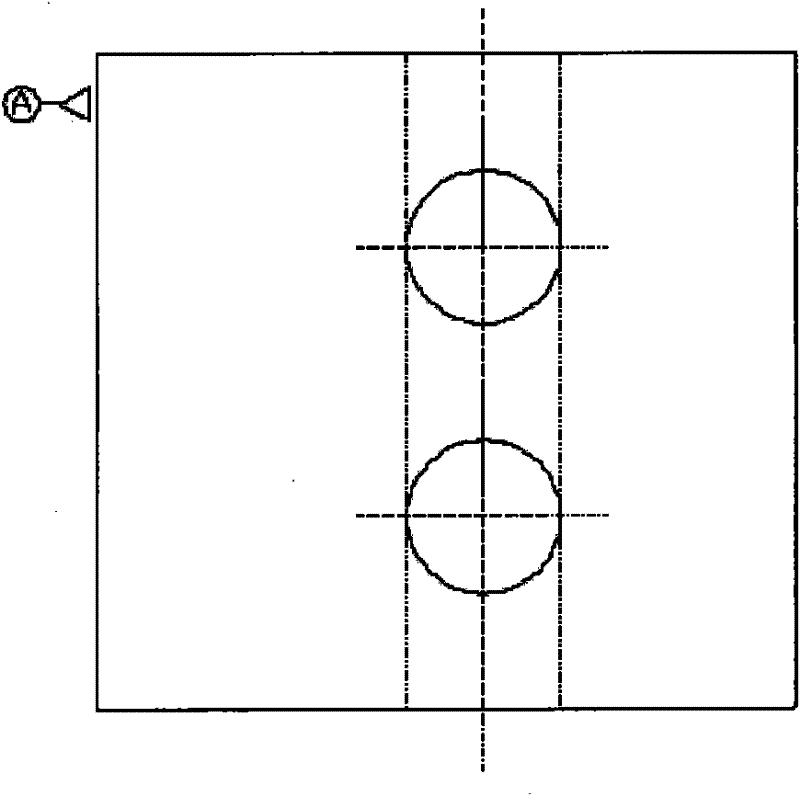

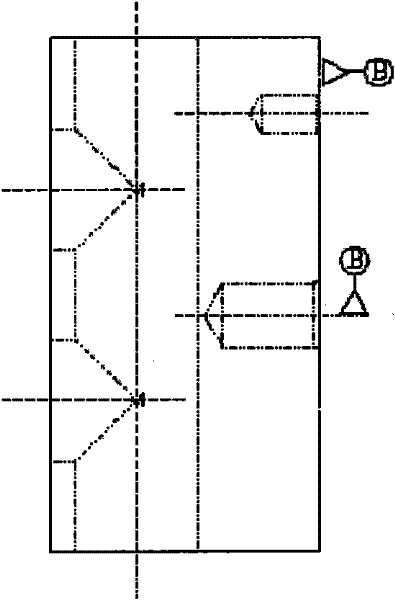

[0023] figure 1 , 2 It is a part drawing, in which it is required to use these three datum planes for positioning, and use the traditional pre-locking mechanism to connect with the clamp body before clamping the workpiece ( Figure 4 ), it is easy to produce uneven attachment between the part reference B and the three positioning points, and it is easy to bruise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com