Anti-counterfeiting bottle cap adhered with colored printing thin film

An anti-counterfeiting bottle cap, colored technology, applied in the direction of printing, production of special varieties of printed matter, printing process, etc., can solve the problems of reduced authenticity, low screen printing efficiency, no protection, etc., to achieve stable quality, reduced production costs, Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

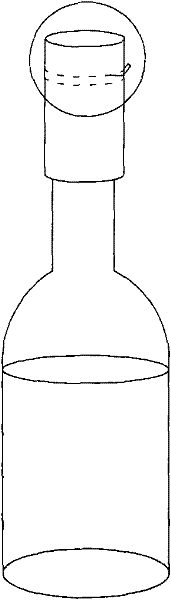

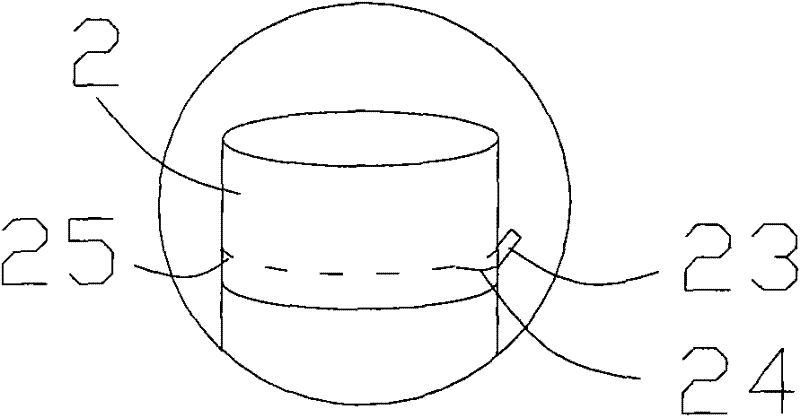

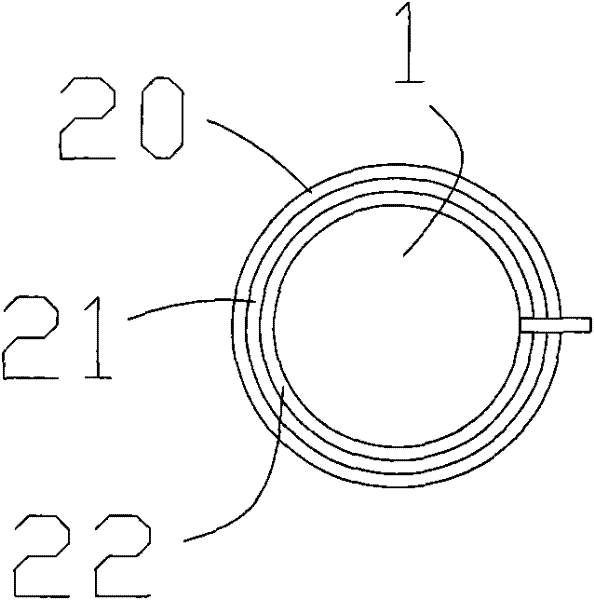

[0024] A kind of anti-counterfeiting bottle cap with color printing sheet veneer of the present invention is mainly aimed at wine products, such as Figure 1 to Figure 4 As shown, the anti-counterfeiting bottle cap includes a shell 1, and an anti-counterfeiting film 2 arranged on the shell 1 for covering the shell 1; the anti-counterfeiting film 2 includes a transparent plastic film 20, and is reversely printed on the transparent plastic film The color printing layer 21, and the metal layer 22 that is arranged on the printing layer 21 and is formed by transferring metal; the anti-counterfeiting film 2 is provided with a guide opening structure 23, and an opening breach 24 associated with the opening structure 23 and Break hidden line 25. When the bottle cap is opened, the opening breach 24 of the anti-counterfeiting film 2 will be broken and broken along the hidden line 24 of the fracture, which cannot be restored after being torn apart, thus achieving the anti-counterfeiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com