Fluid flow direction switch

A converter and fluid technology, applied in the direction of multi-way valves, engine components, mechanical equipment, etc., can solve problems such as cancer and various diseases, achieve the effects of preventing reproduction, wide application range, and eliminating secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

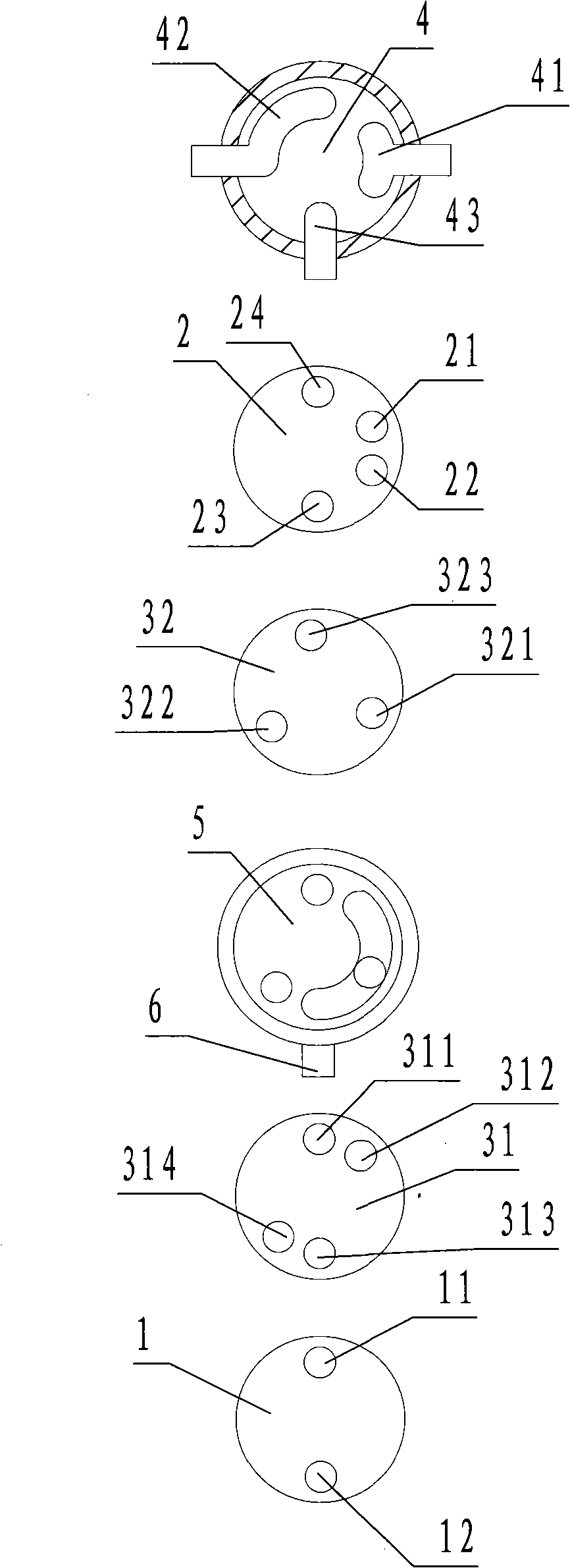

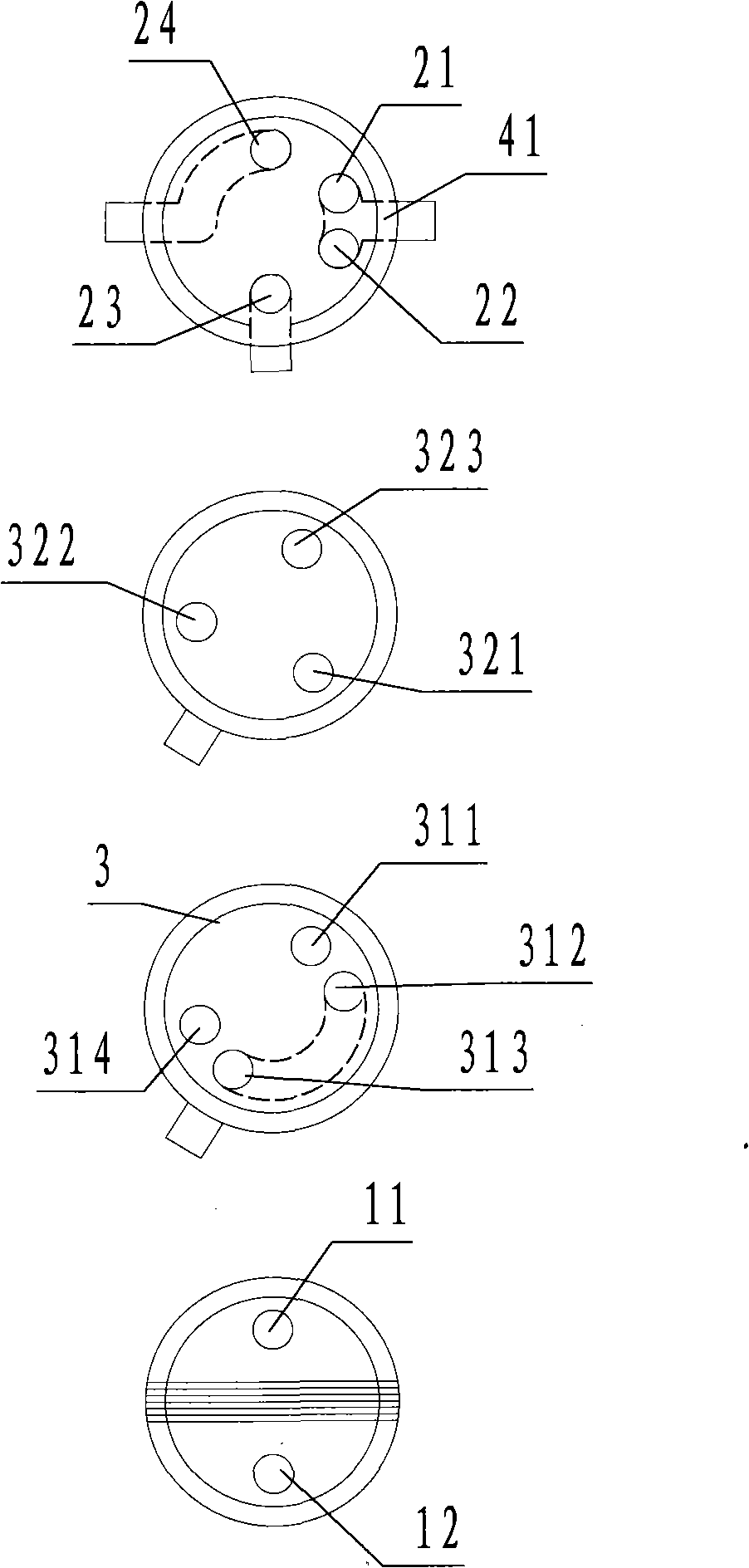

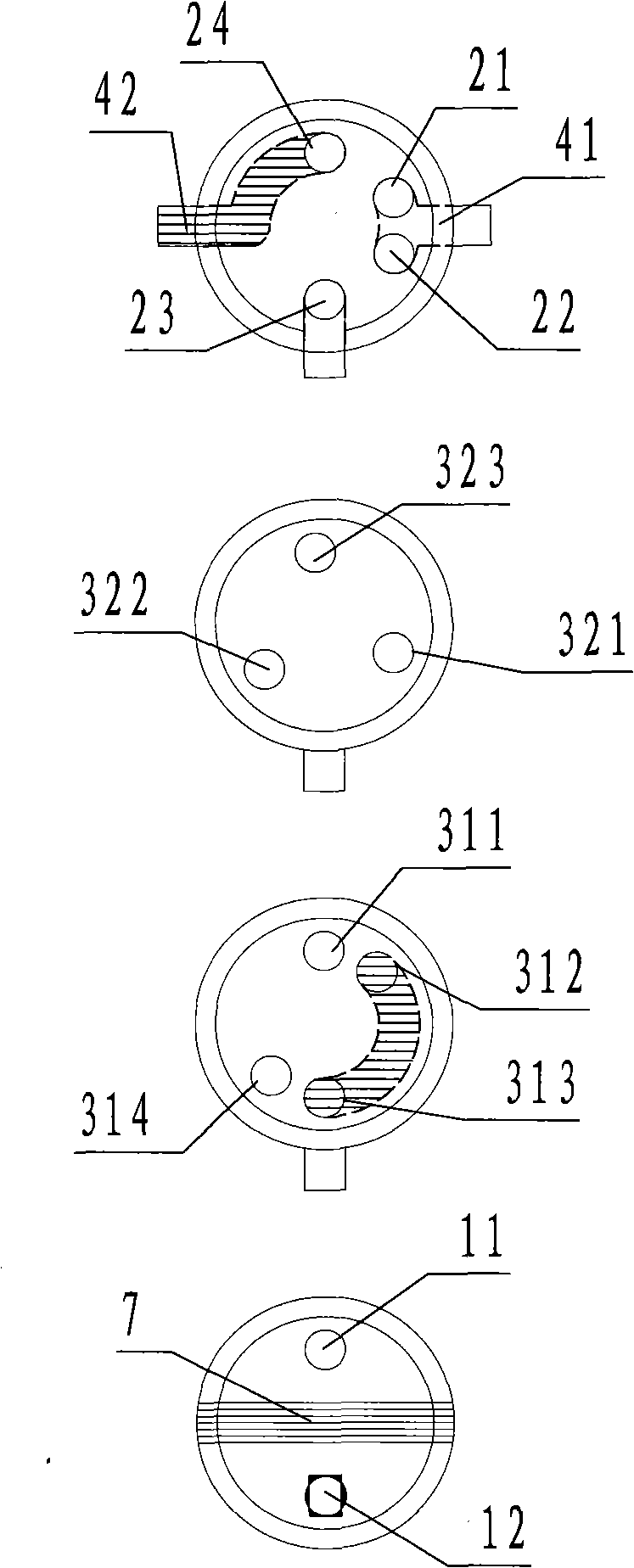

[0026] a kind of like Figure 5 The shown fluid flow direction converter includes the upper static plate 1, the lower static plate 2 and the moving plate 3 between the two static plates on both sides. The upper static plate communicates with the inner cavity of the water purification equipment and communicates with the net The upper static piece communicating with the inner cavity of the water equipment is provided with 2 through holes communicating with the upper and lower ends of the upper static piece. The 2 through holes are distributed at both ends of the same diameter and located at the same circumference. There are 4 through holes on the upper and lower ends of the static plate, 2 of which are distributed at both ends of the same diameter of the lower static plate, and the other two through holes on the lower static plate are distributed on the same side of this diameter, and the four through holes on the lower static plate are distributed on the same side of the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com