A water purifier controlled by a four-way valve

A four-sided valve, water purifier technology, applied in water treatment parameter control, water/sewage treatment, water treatment under pressure conditions, etc., can solve the problems of limited use site, low water volume of RO mechanism, and low total water volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

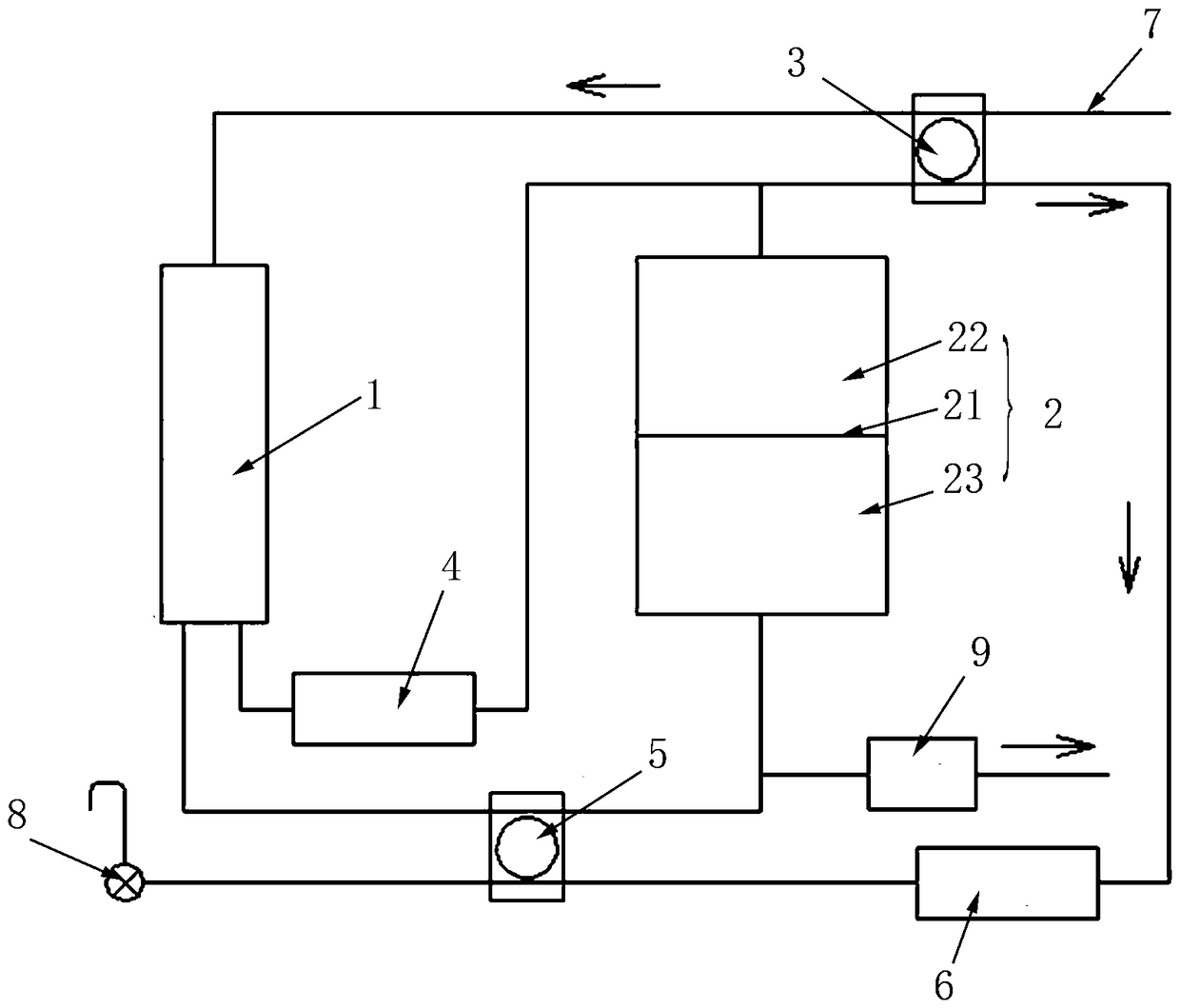

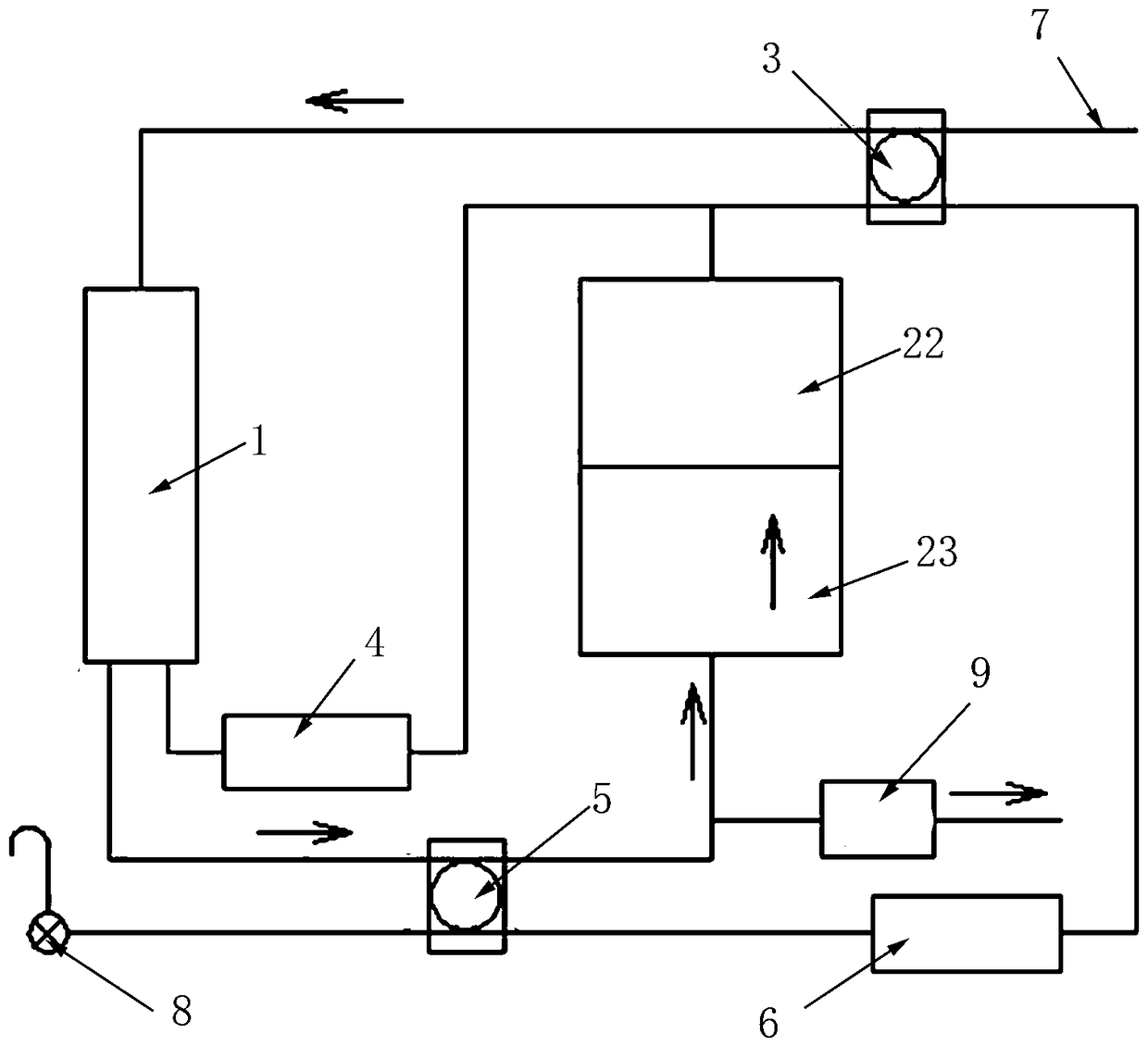

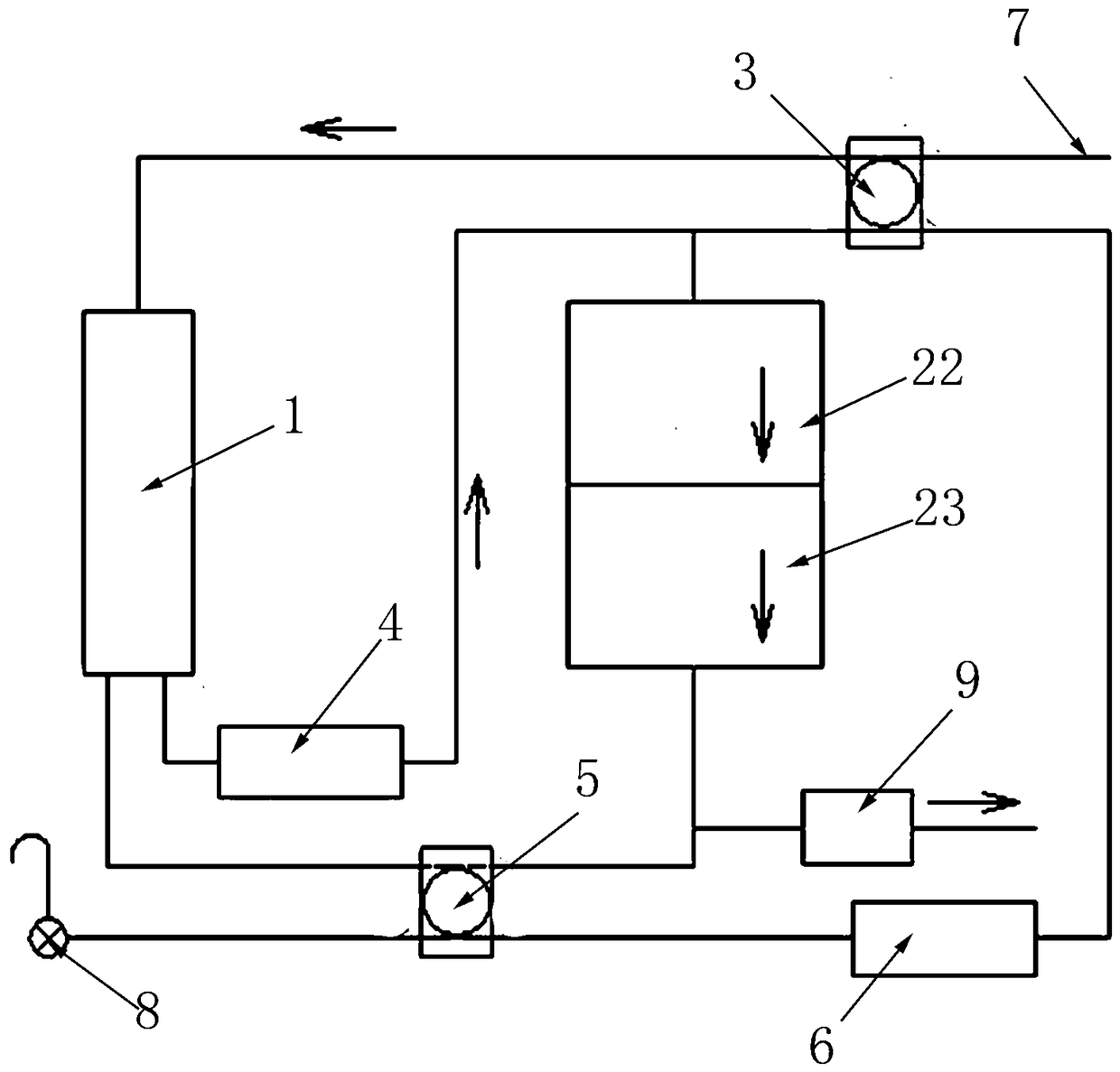

[0020] See attached picture. This embodiment includes RO filter element 1 and pressure barrel 2, and described pressure barrel 2 divides pressure barrel into pure water area 22 and waste water area 23 through diaphragm 21, diaphragm 21 is a flexible structure, between pure water area 22 and waste water area 23 The water inlet end of the RO filter element 1 communicates with the tap water inlet 7 through the high-pressure passage of the first four-way valve 3, the high-pressure passage inlet of the first four-way valve 3 is connected to the tap water inlet 7, and the high-pressure passage outlet is connected to the RO filter element 1; The wastewater end of the RO filter element 1 is connected to the inlet of the high-pressure passage of the second four-way valve 5, and the outlet of the high-pressure passage of the second four-way valve 5 is connected to a tee, and the other end of the tee is connected to the waste water area 23 of the pressure barrel. The three ends are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com