Magnetic microsphere as well as preparation and preparation method thereof used for purifying histidine tag protein

A technology of histidine labeling and magnetic microspheres, applied in the field of magnetic microspheres, can solve the problems of cumbersome application procedures, difficult fast adsorption and movement, low response, etc., achieve efficient chelation of metal ions, and simple purification and separation process , Guarantee the effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

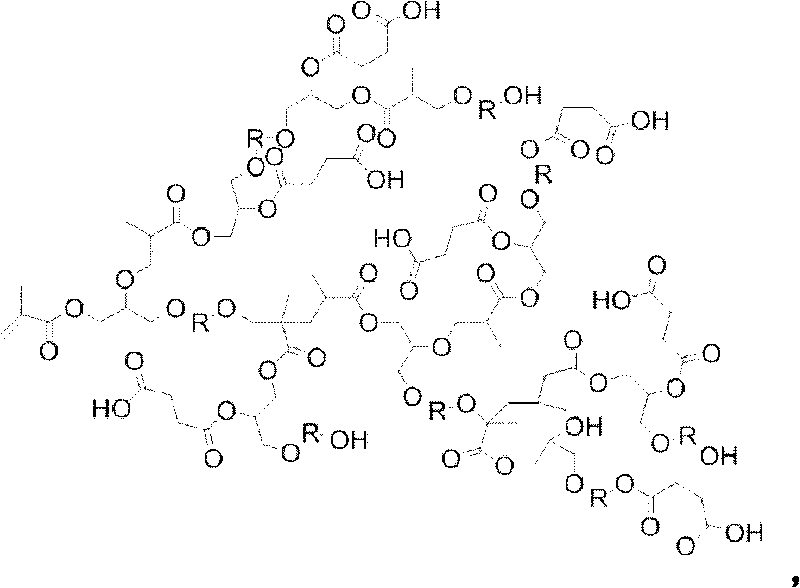

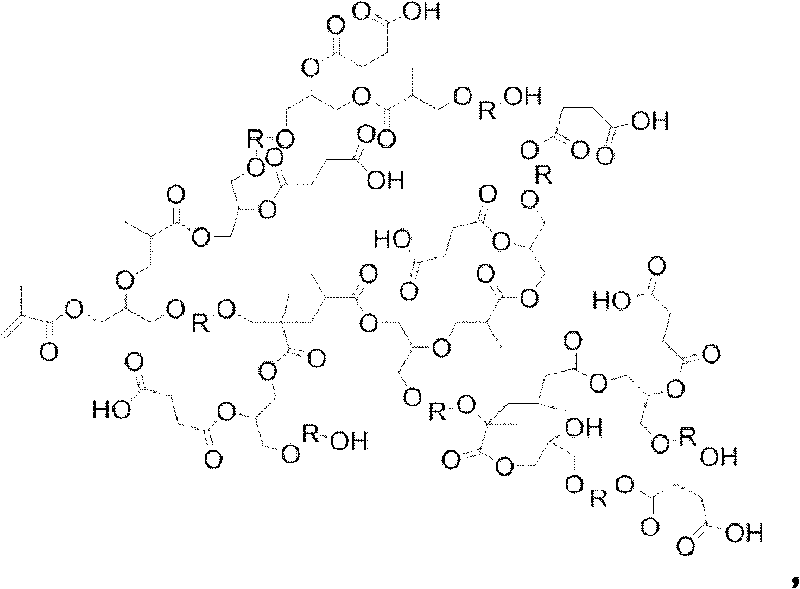

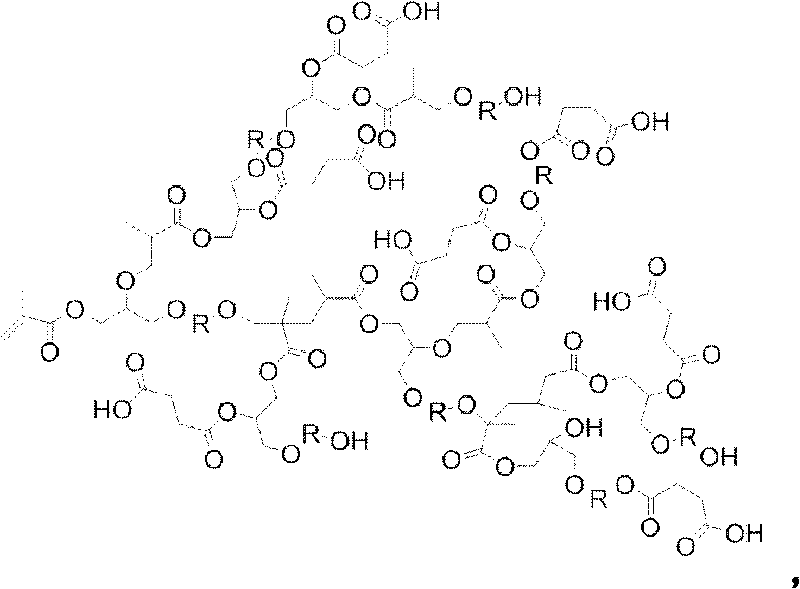

Method used

Image

Examples

Embodiment 1

[0037] (1) The method proposed in the Chinese invention patent ZL 2006100279617 was used to prepare magnetic silica microspheres with a particle size of 200nm in the surface-coated silica shell. Freeze-dry the silica microspheres, weigh 6g of freeze-dried magnetic particles, add them to a 100mL three-necked flask, and add 60mL of toluene to the flask; start stirring, put them in an oil bath at 120°C, and add them after reflux for 30 minutes 5 g of γ-aminopropyltrimethoxysilane was refluxed for 2 h. After the reaction was finished, ultrasonicated for 30 seconds, poured into a beaker, and separated under the assistance of a strong magnetic field, then added 50mL of toluene, ultrasonicated for 1 minute, and separated and washed by a strong magnetic field. After repeated operations three times, the obtained amino-modified magnetic microspheres Put it into a vacuum drying oven at 120°C for a vacuum reaction for 12 hours, and finally place the obtained magnetic microspheres in a sam...

Embodiment 2

[0044] (1) The method proposed in Chinese invention patent ZL 2006100279617 was used to prepare magnetic silica microspheres coated with a silica shell. The difference is that the inner core of the magnetic particle aggregates in the microspheres is 900nm, and the silicon oxide shell coating method is the same as that of the Chinese invention patent ZL 2006100279617, so the particle size of the finally obtained silicon oxide magnetic microspheres is 1000nm. Freeze-dry the silica microspheres, weigh 6g of freeze-dried magnetic particles, add them to a 100mL three-necked flask, and add 20mL of toluene to the flask; stir, put them in an oil bath at 120°C, reflux for 30 minutes, and then add γ - Aminopropyltriethoxysilane 1g, reflux reaction for 2h. After the reaction was finished, ultrasonicated for 30 seconds, poured into a beaker, and separated under the assistance of a strong magnetic field, then added 50mL of toluene, ultrasonicated for 1 minute, and separated and washed by a...

Embodiment 3

[0051] (1) The method proposed in Chinese invention patent ZL 2006100279617 was used to prepare magnetic silica microspheres coated with a silica shell. The difference is that the inner core of the magnetic particle aggregates in the microspheres is 900nm, and the silicon oxide shell coating method is the same as that of the Chinese invention patent ZL 2006100279617, so the particle size of the finally obtained silicon oxide magnetic microspheres is 1000nm. Freeze-dry the silicon oxide microspheres, weigh 6g of freeze-dried magnetic particles, add them to a 100mL three-necked flask, and add 20mL of toluene to the flask; stir, put them in an oil bath at 120°C, reflux for 30 minutes, and then add N -0.5 g of β(aminoethyl)-γ-aminopropyltrimethoxysilane, reflux for 2 hours. After the reaction was finished, ultrasonicated for 30 seconds, poured into a beaker, and separated under the assistance of a strong magnetic field, then added 50mL of toluene, ultrasonicated for 1 minute, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com