Ball mill capable of monitoring motion of internal medium

A medium motion, ball mill technology, applied in grain processing and other directions, can solve the problems of lack of detection equipment, inability to observe and analyze different motion states, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

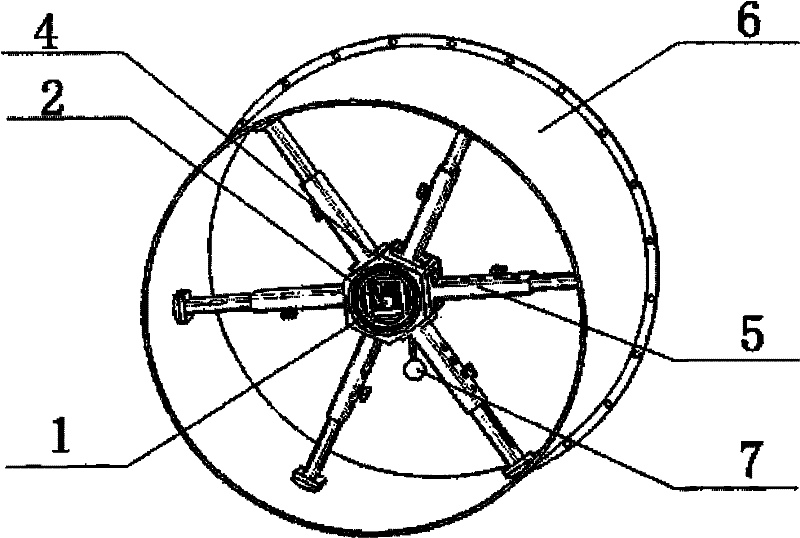

[0017] With reference to accompanying drawing, further illustrate the present invention:

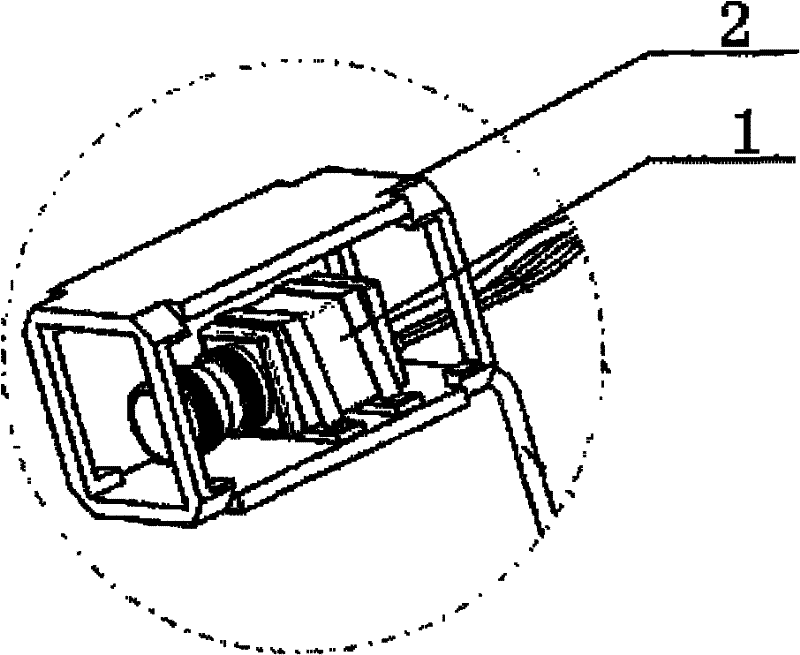

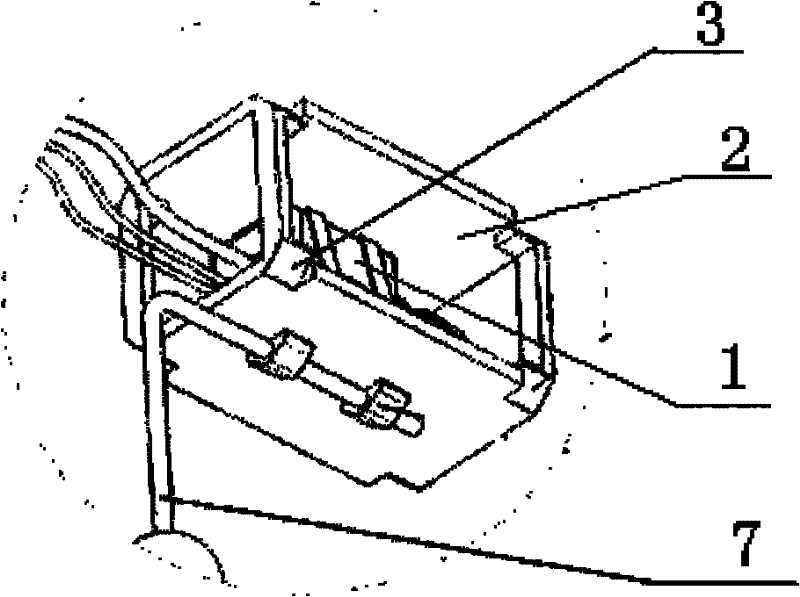

[0018] A ball mill that can monitor the movement of the internal medium. The detection cabin of the ball mill is provided with a monitoring device. The monitoring device includes a camera 1 facing the grinding cabin and a fixed frame 2 for fixing the camera 1. The fixed frame 2 passes through the The bearing 3 is connected with the protective shell 4, and the protective shell 4 is connected with the ball mill cylinder 6 through the support rod 5; the fixed frame 2 is provided with a balance friction moment caused by the bearing 3, so that the camera 1 and its fixed frame 2 7. The counterweight is isolated from the rotational movement of the outside.

[0019] The support rod 5 includes a front support arm 51 fixed on the protective shell 4 and a rear support arm 52 against the inner wall of the drum 6. The front support arm 51 is provided with a The rear support arm 52 is inserted into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com