Straight-paper-path flexo printing machine

A flexographic printing machine, flat paper technology, applied to printing machines, rotary printing machines, rotary printing machines, etc., can solve the problems of continuous high-speed printing, reduced work efficiency, high printing cost, etc., and achieve high-speed continuous operation , stable paper strength and high printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below:

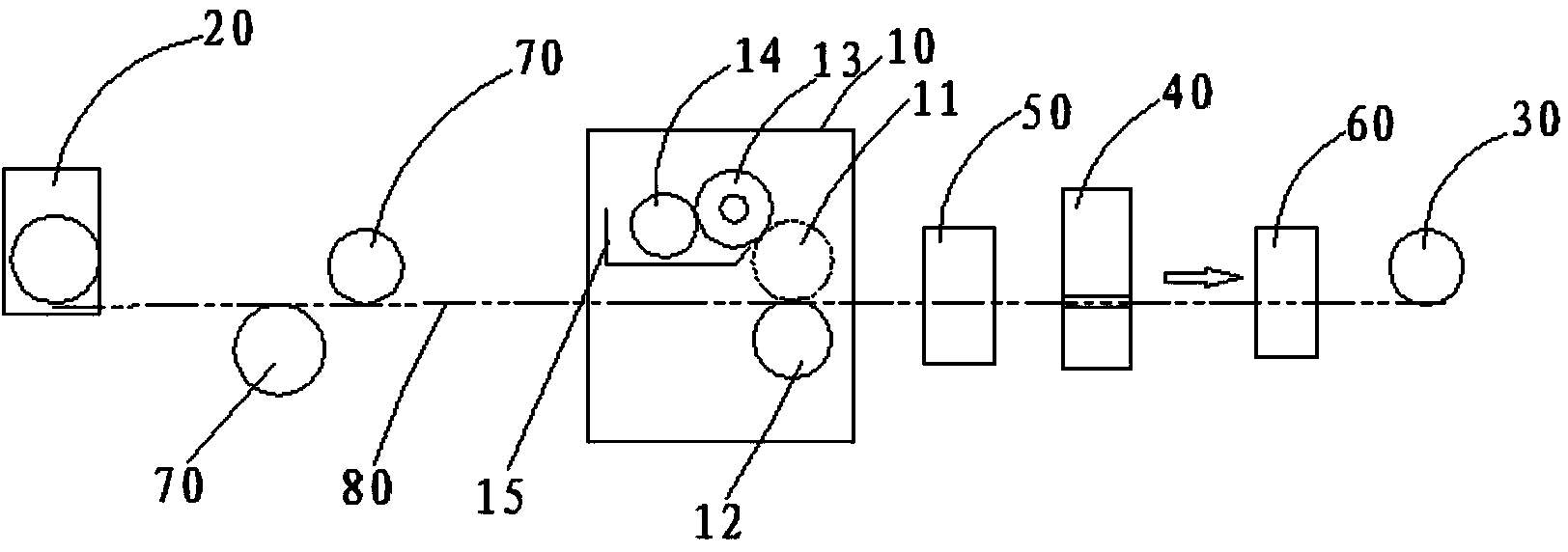

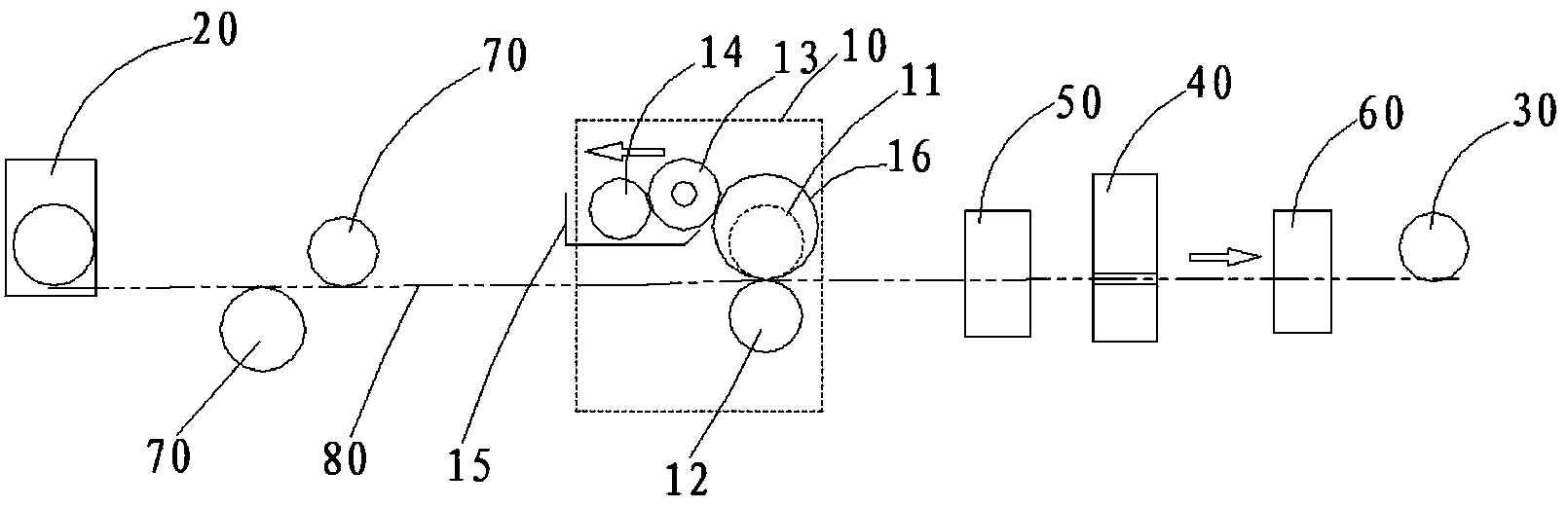

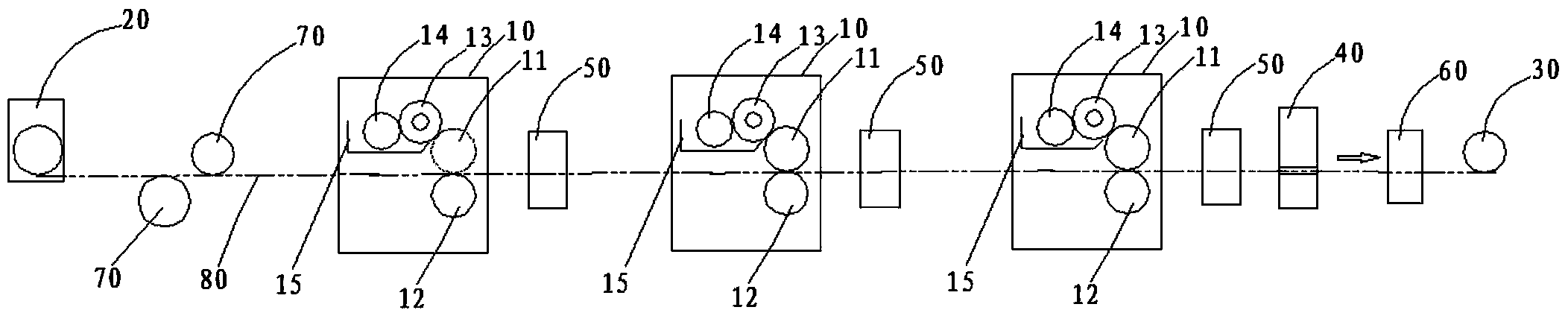

[0025] Such as Figure 1-3 As shown, the flat paper path flexographic printing machine of the present invention includes a feeding unit 20, a printing unit 10, a drying unit 40, and a receiving unit 30 arranged sequentially on a straight paper path 80, and the printing unit 10 includes The ink tray 15 that is arranged on one side of the paper path 80, the ink transfer roller 14 that is arranged on the ink tray 15, the anilox roller 13 that is tangent to the ink transfer roller 14, and the printing plate roller that is tangential to the anilox roller 13, set The printing roller 12 on the other side of the paper path 80 is tangent to the printing plate roller.

[0026] By adopting the flat paper road flexographic printing machine of the present invention, the paper is discharged from the feeding unit 20 and enters the printing unit 10, and the printing plate roller in the printing unit 10 prints the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com