A 3D printing equipment and construction method for cement concrete pavement

A cement concrete and 3D printing technology, applied in the field of road paving, can solve the problems of difficult to achieve fast, large-scale, long-distance road printing, and achieve the effects of eliminating roughness, eliminating road bubbles, and increasing skid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

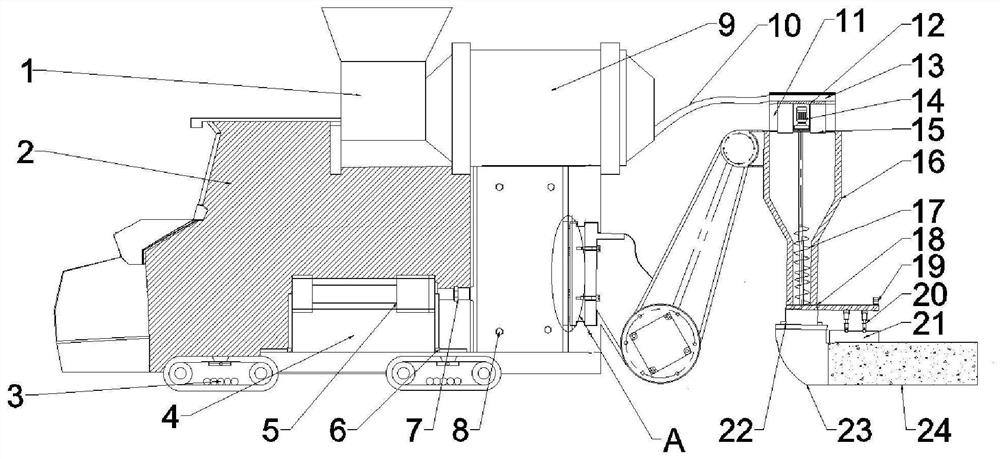

[0039] Such as Figure 1-5 As shown, this embodiment provides a cement concrete pavement 3D printing equipment, including vehicle-mounted system 2, batching system, control system, printing system and leveling system, wherein,

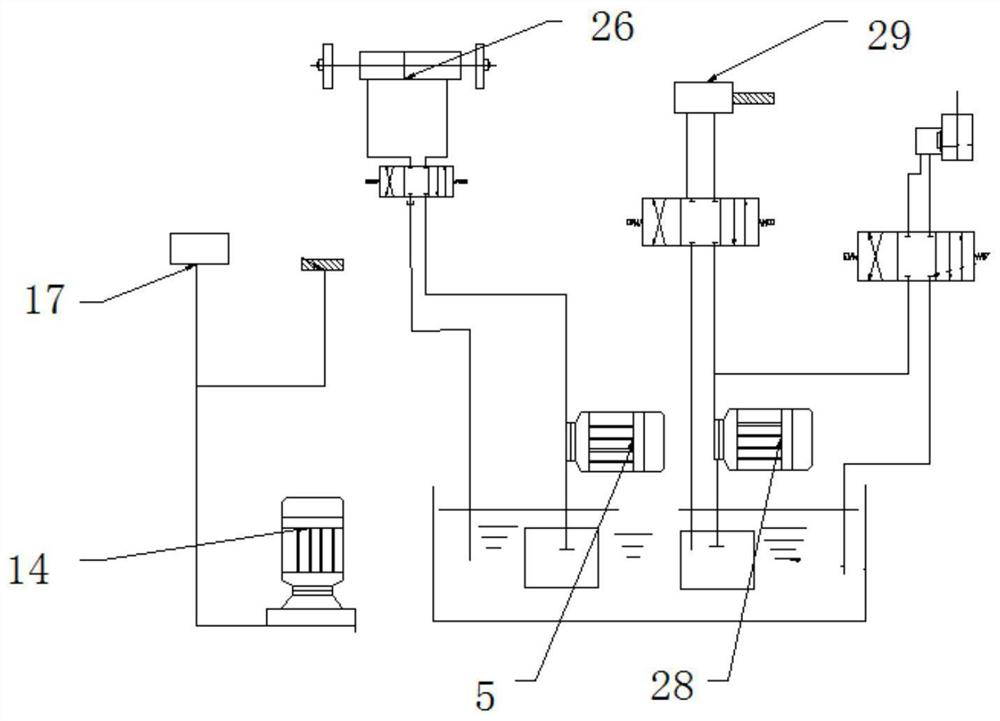

[0040] The vehicle-mounted system is equipped with a batching system, which is connected to a printing system. The printing system is equipped with a control system. The concrete is laid on the road through the printing system and the control system. The printing system is equipped with a leveling system. The paved road surface is leveled. The vehicle-mounted system is an existing vehicle equipment, which is driven by crawler-type electric drive wheels 3 .

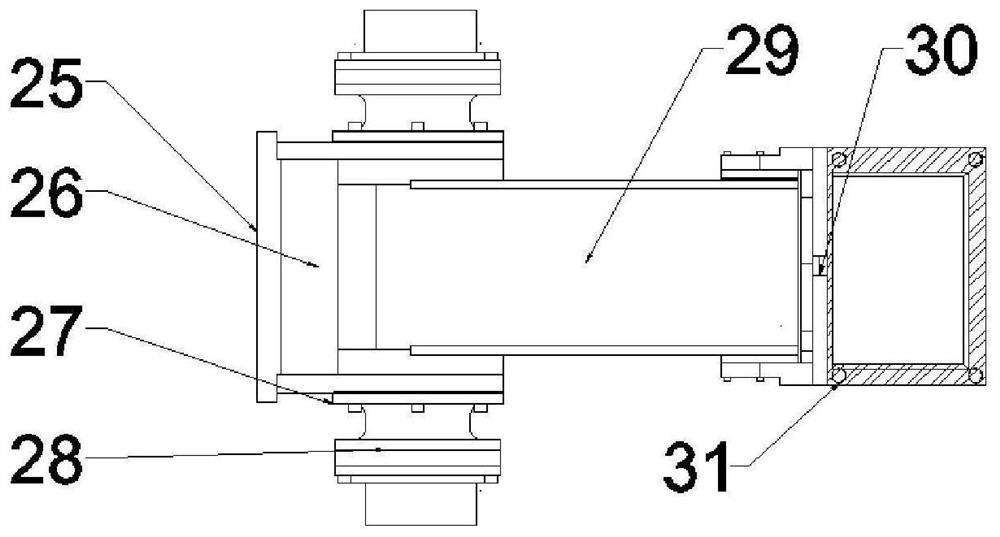

[0041] The printing system includes a servo drive mechanism, a mechanical arm drive mechanism and a forming mechanism;

[0042] The servo drive mechanism includes a hydraulic cylinder 4, a hydraulic motor 5, a guide rail drive device 8 and a linear slide rail 34. The bottom of the vehicle system ...

Embodiment 2

[0057] A construction method for cement concrete pavement 3D printing equipment, the operation steps are as described in Example 1, the difference is that in step (2), the materials required for the concrete 24 are as follows: each cubic meter of concrete includes the following components by weight: 330-360kg of cement, 140-160kg of fly ash, 175-185kg of water, 750-800kg of river sand, 860-900kg of gravel, 0.18-0.23kg of air-entraining agent, 0.06-0.12kg of high-efficiency water reducing agent and thickening rheology Dosage 0.20-0.46kg.

[0058] The cement is Portland cement P·I42.5, and the fly ash is Class F fly ash with an average particle size of 24 μm, which is used to improve the fluidity of the concrete, and the usage amount reaches 40% of the cement, and the fine aggregate is river sand. The fineness modulus of river sand is 2.95-3.36, the specific gravity is 2.6-2.65, the water absorption range of river sand is 1.09-2.32, the particle size range of river sand is 0-4.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com