Modularized water electrolysis hydrogen production system and control method thereof

A hydrogen production system and water electrolysis technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve problems such as slow response of electrolyzers, potential safety hazards, and unstable hydrogen production, so as to reduce operation and maintenance costs and avoid frequent start-up The effect of stopping and improving the quick response ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

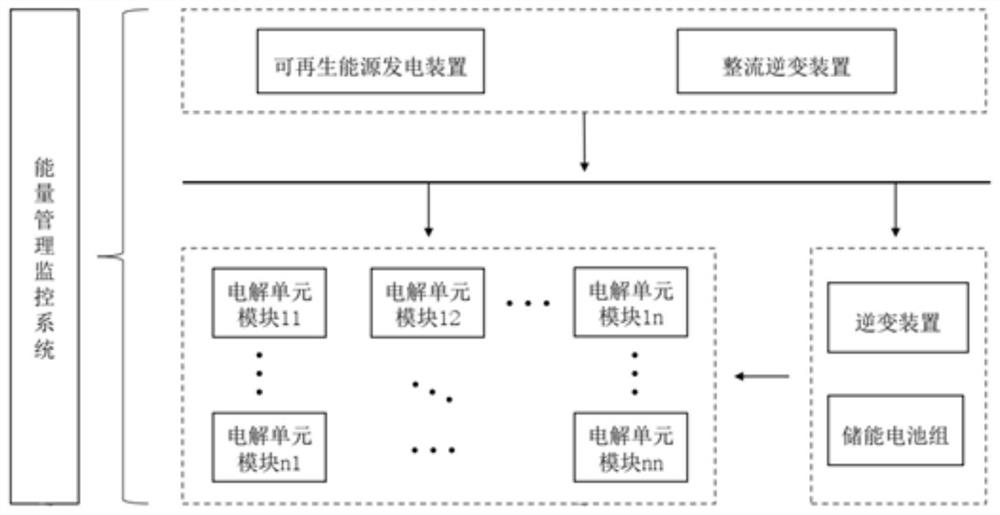

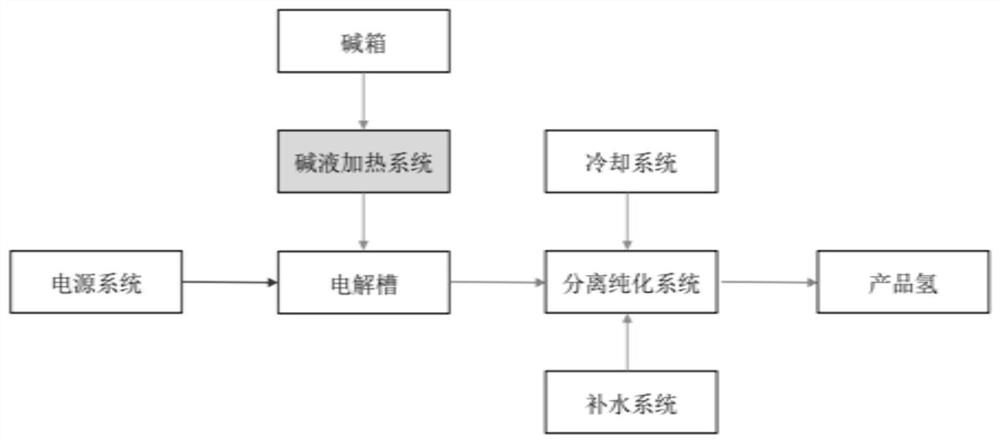

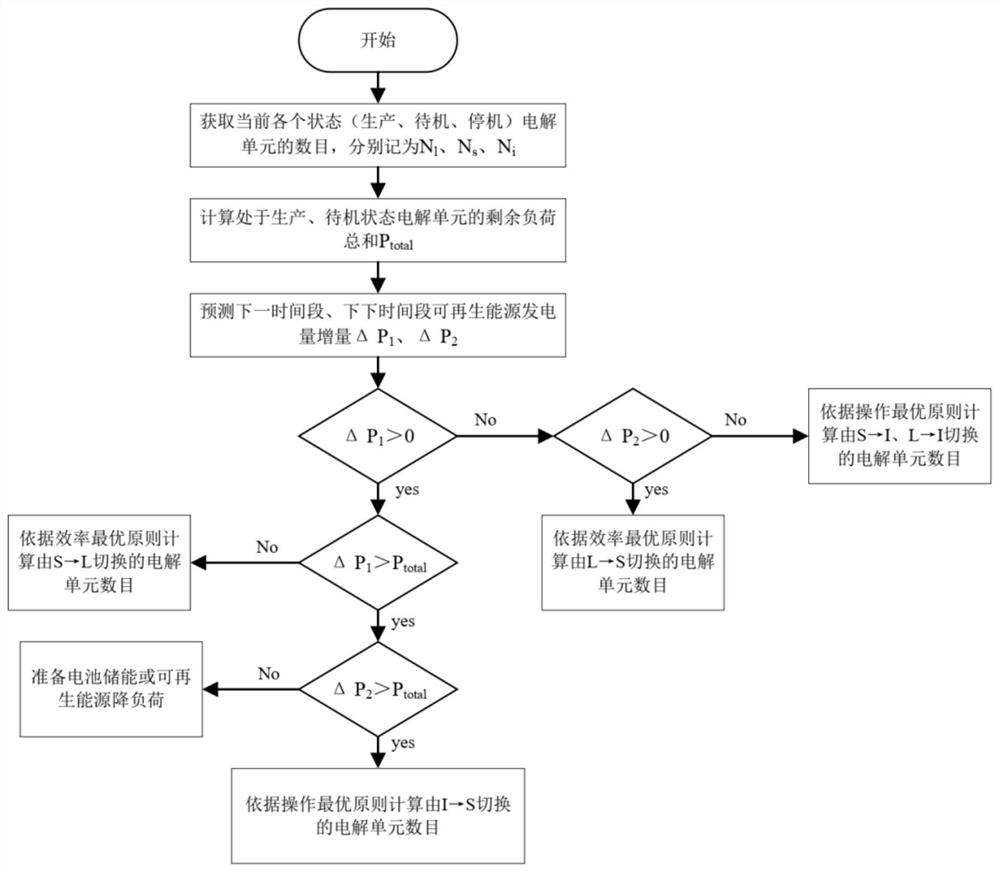

[0030] see figure 1 , 2 The modular water electrolysis hydrogen production system provided in this embodiment includes a renewable energy power generation system, an electrolysis unit module group, an energy storage system, and an energy management monitoring system. The renewable energy power generation system includes a renewable energy power generation device and a rectifier inverter Transformation device, the electrolytic unit module group includes several electrolytic unit modules, the electrolytic unit modules are connected in series / parallel or work alone, the electrolytic unit modules include a power supply system, an electrolytic cell, and an alkali heating system, and the alkali The liquid heating system heats the lye that enters the electrolytic cell, the power system is electrically connected to the electrolytic cell, the energy storage system includes an inverter device and an energy storage battery pack, and the power system of each electrolytic cell module is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com