Split type booster efficient rudder

A split-type, boosting technology, applied in steering gear, rudder steering, ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

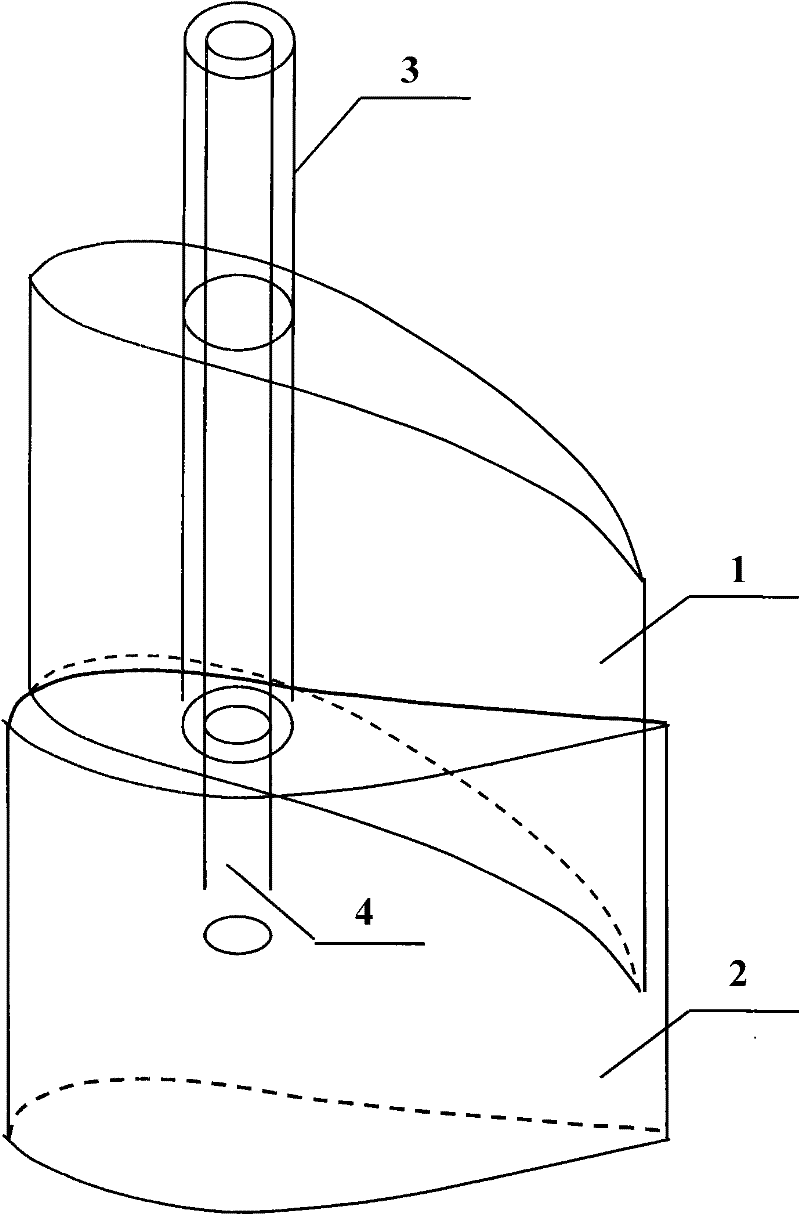

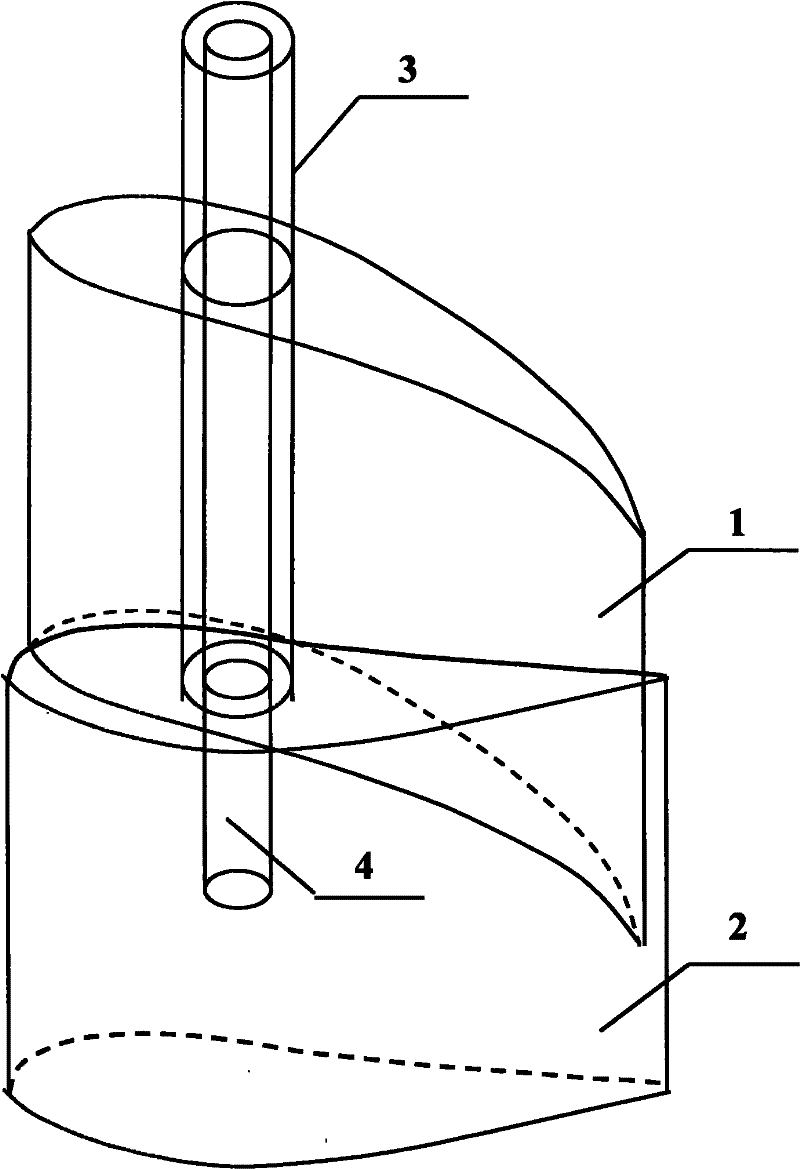

[0008] The rudder blade is divided into two parts with the propeller axis as the boundary, which are independent up and down and controlled separately, that is, the upper rudder blade 1 and the lower rudder blade 2 . The upper rudder blade 1 and the lower rudder blade 2 are respectively equipped with an upper rudder blade rudder stock 3 and a lower rudder blade rudder stock 4 . Wherein the upper rudder blade rudder stock 3 of the upper rudder blade 1 is a hollow shaft, the lower rudder blade rudder stock 4 of the lower rudder blade 2 is a solid shaft, and the upper rudder blade rudder stock 3 is sleeved on the lower rudder blade rudder stock 4 to form a coaxial manner. The equilibrium position of the upper rudder blade 1 and the lower rudder blade 2 (that is, when the ship is not steering to keep the ship sailing straight or called the rudder) is arranged according to the rotation direction of the propeller and deflects an angle against the rotation direction, forming an X-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com