Hollow body of hollow floor system

A hollow floor and hollow body technology, which is applied in the direction of floors, formwork/formwork/work frames, building components, etc., can solve problems such as unsatisfactory, achieve the effects of increasing weight, enhancing resistance, and improving anti-seismic cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

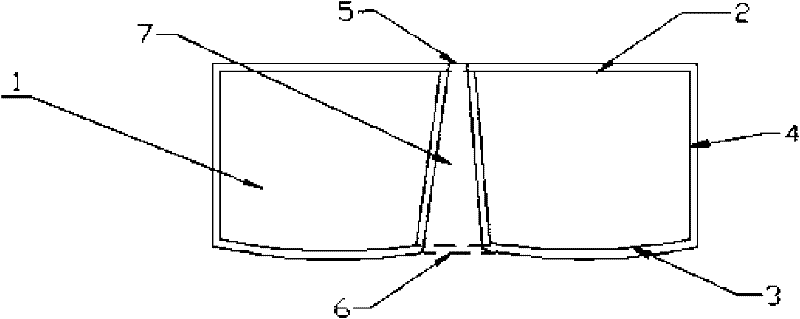

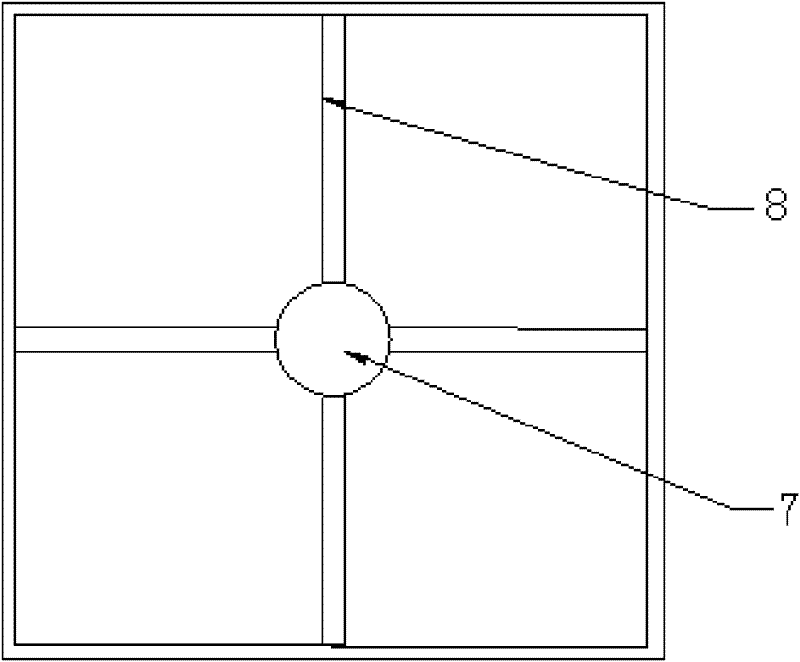

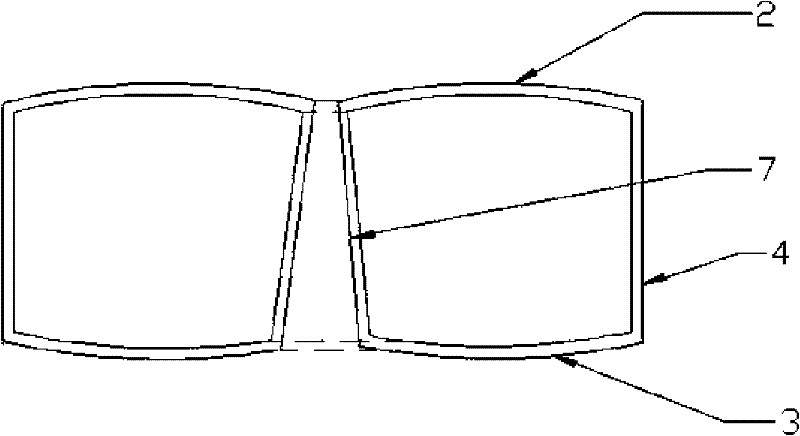

[0025] The present invention will be further described now in conjunction with accompanying drawing, as figure 1 As shown, the hollow body 1 in this program is composed of a bottom plate 3, a middle frame 4 and a capped top cover 2. The top cover 2 is manufactured separately and has a hole 5 on it. The bottom plate 3 and the frame body 4 of the hollow body 1 pass through The mold is molded at one time, and two arcs are formed at the bottom of the mold, and multiple arcs can also be made as required. The bottom surface of the mold is left with a hole-making column in the concave part between the arc and the arc. The position is opposite to the hole 5 on the top cover 2, and the corresponding pipe 7 is installed on the hole 6 of the bottom plate 3, and the other end of the pipe 7 is connected to the hole 5 on the top cover 2, and some supporting top covers are placed on the bottom plate 3 as required Columns, such as plastic and wooden columns, can also be poured with concrete m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com