Device for fixing electrical mechanism on frame base

A frame and electrical technology, applied in the installation of electrical components, coupling devices, support structures, etc., can solve the problems of increased cost and increased installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

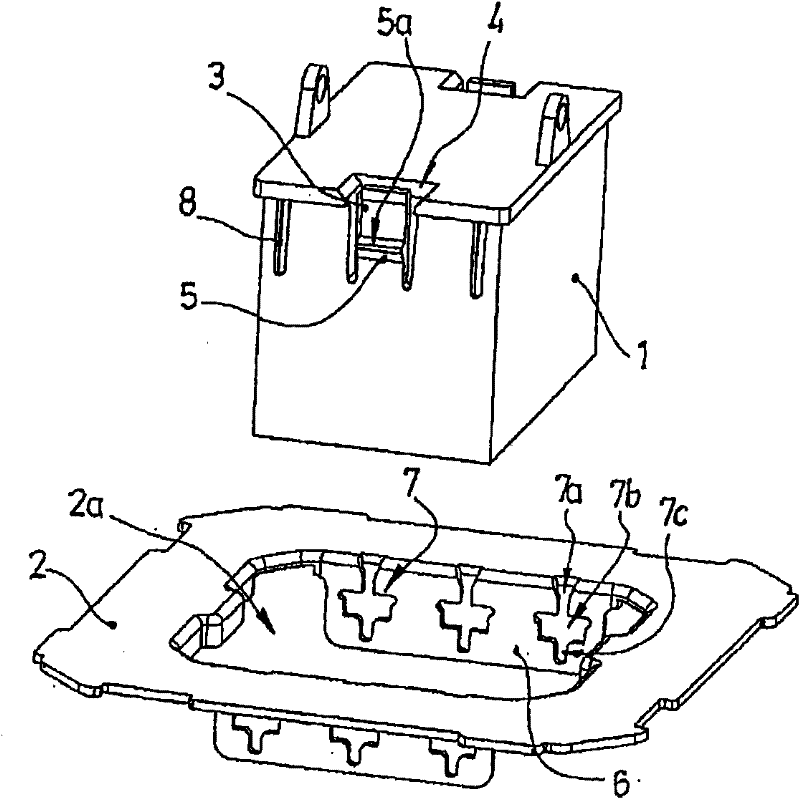

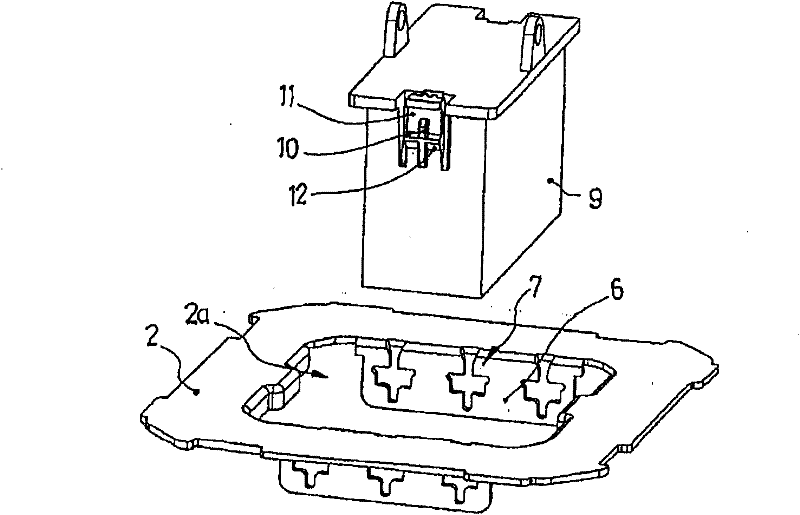

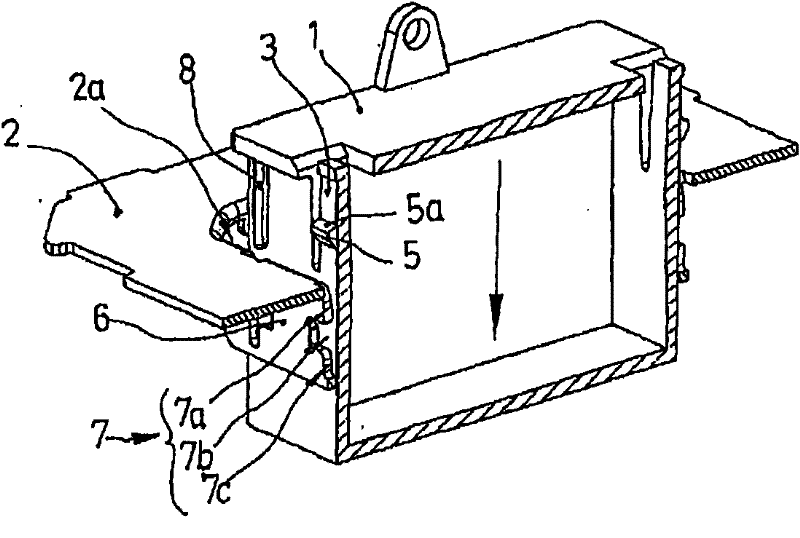

[0021] According to the drawings, the fixing device for the purpose of the present invention can be applied to various functional electrical mechanisms. These electrical mechanisms are integrated in the base 1. The fixing device can be directly fixed to the central opening 2a of the frame base 2 without any fixing, Connect or clamp accessories.

[0022] An important feature of the device that is the object of the present invention is that once the base 1 is set in the central opening 2a of the frame base 2, it can be fixed in the aforementioned central opening 2a of the frame base 2, without swinging in the front-to-rear direction, nor Will move sideways in the horizontal direction.

[0023] When the base body is set in its installation position, due to the two vertical guide flanges 8 symmetrically arranged on each front side of the base body 1, the sliding of the base body 1 into the central opening 2a can be guided and thus centered. .

[0024] These vertical guide flanges 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com