Roll mill

A rolling mill and grinding plate technology, which is applied in the direction of mechanical equipment, grain processing, belt/chain/gear, etc., can solve the problems of disturbing the grinding bed, unfavorable, disturbing the grinding process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

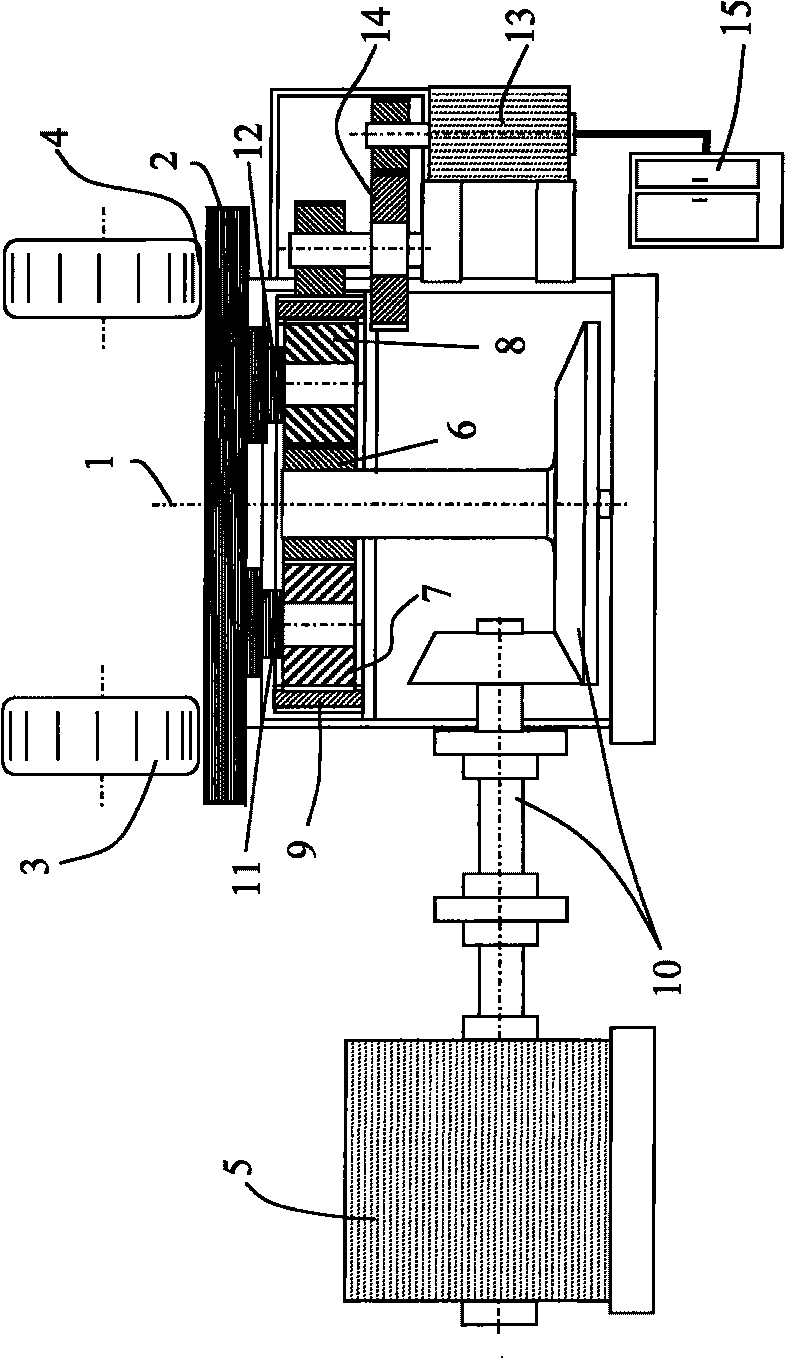

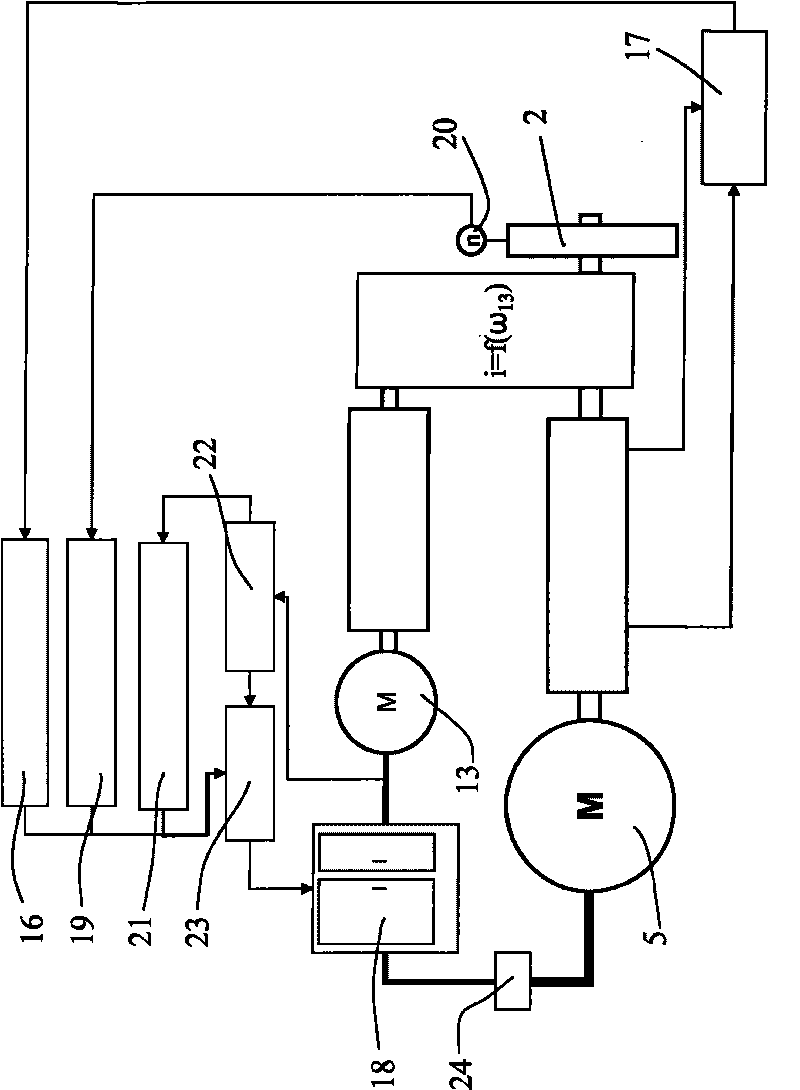

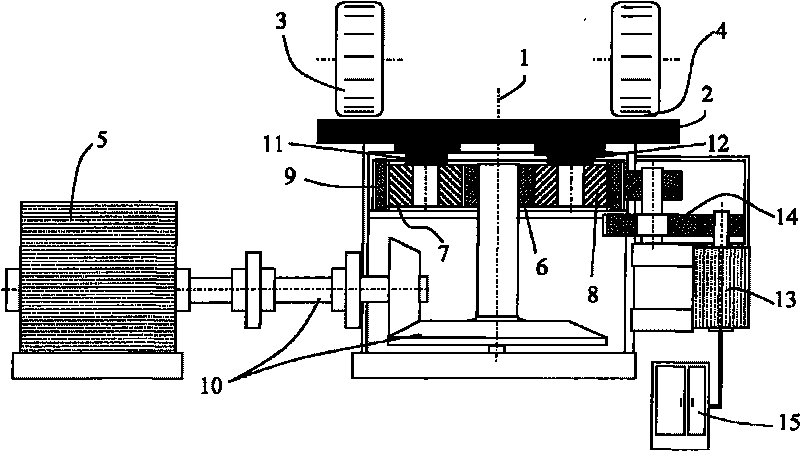

[0017] figure 1 The roller mill shown basically comprises a grinding plate 2 rotatable about an axis of rotation 1 , at least one grinding roller 3 , 4 in rolling engagement with said grinding plate, and a main drive system 5 for driving said grinding plate.

[0018] The main drive system 5 includes a planetary gear with a sun gear 6 , a plurality of planet gears 7 , 8 and a ring gear 9 . The main drive system 5 drives the sun gear 6 via the main drive 10 .

[0019] The planet wheels 7 , 8 are connected to the grinding plate 2 via planet carriers 11 , 12 such that the grinding plate can rotate about the axis of rotation 1 . In this arrangement, the axis of rotation 1 is oriented vertically.

[0020] Furthermore, an auxiliary drive system 13 is provided for driving the grinding plate 2 . To this end, the ring gear 9 of the planetary gear is rotatably arranged and connected to a secondary transmission 13 via a secondary transmission 14 .

[0021] The secondary drive system 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com