Rocker clamping fixture

A technology of clamping clips and screw rods, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of low production efficiency, time-consuming clamping and loosening of clamps, etc., and achieve the effect of simple structure, fast clamping or loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

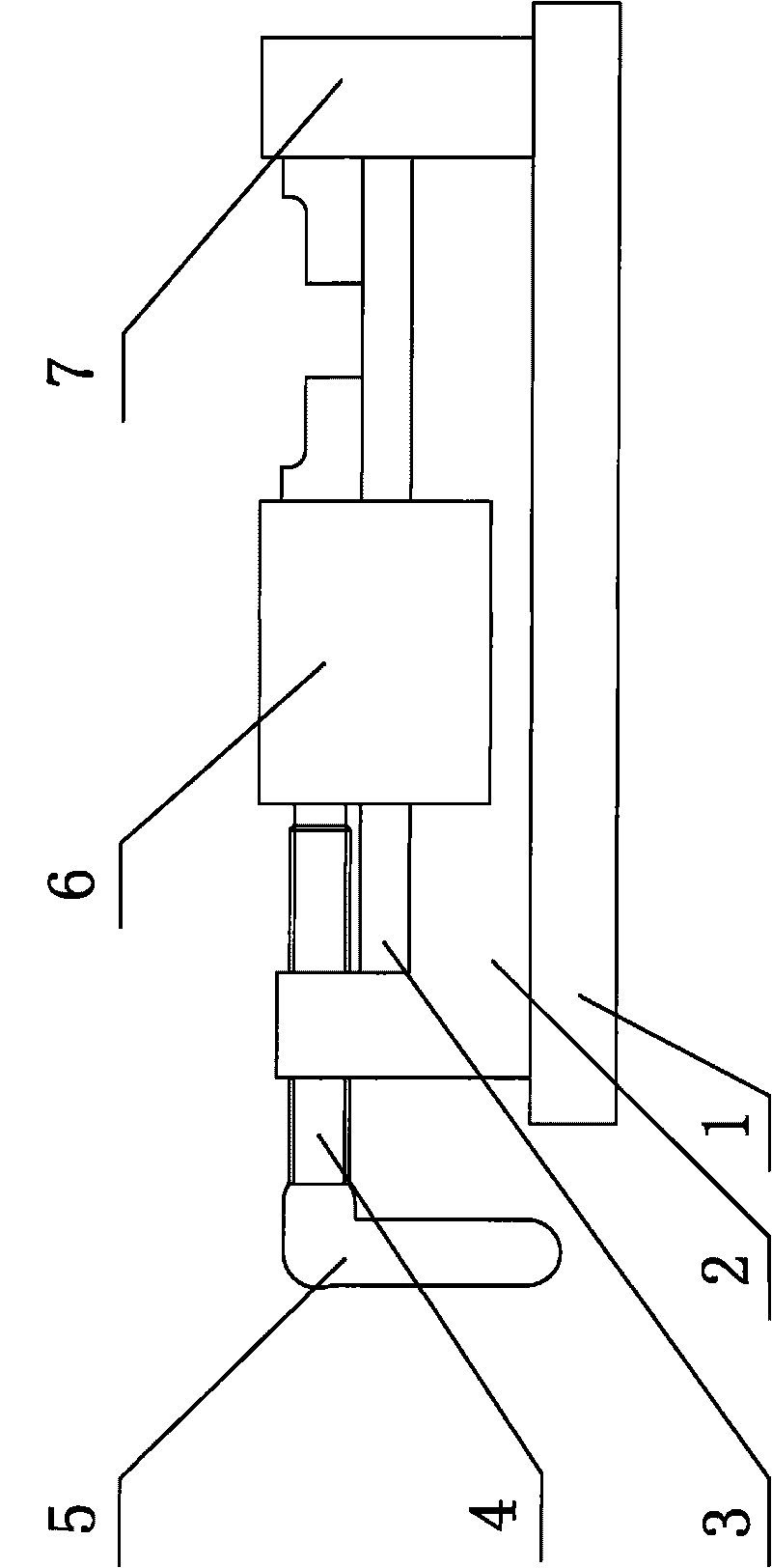

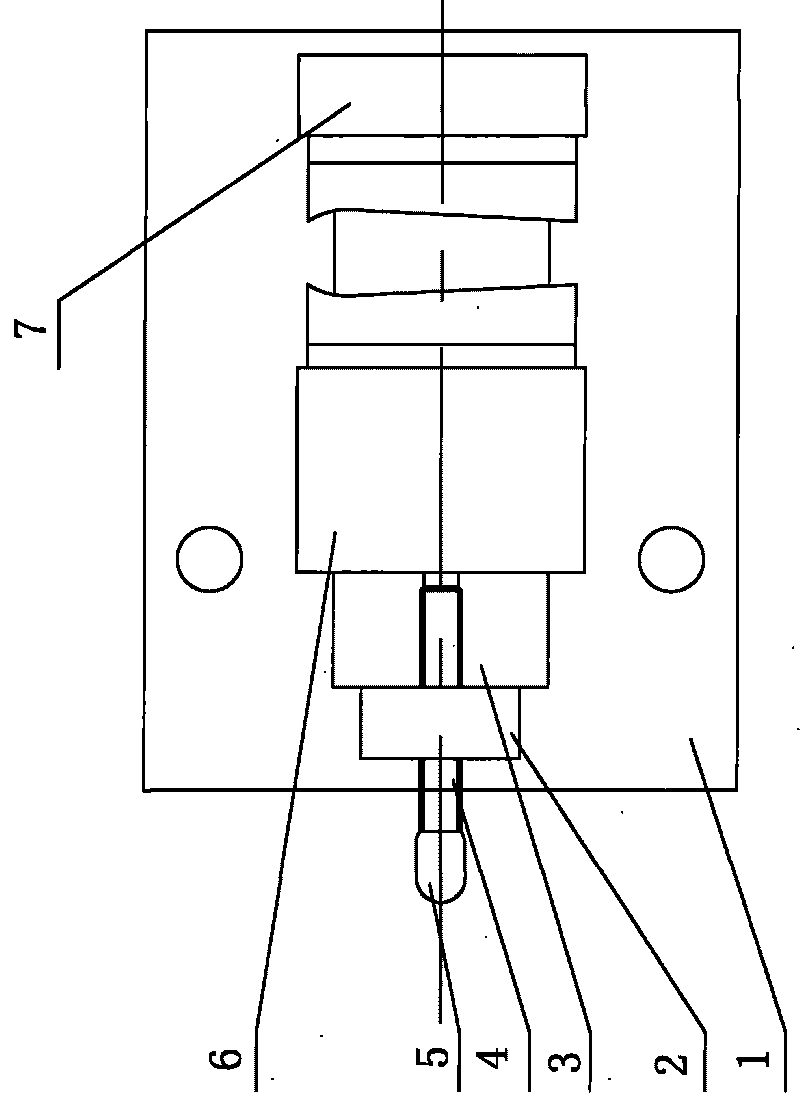

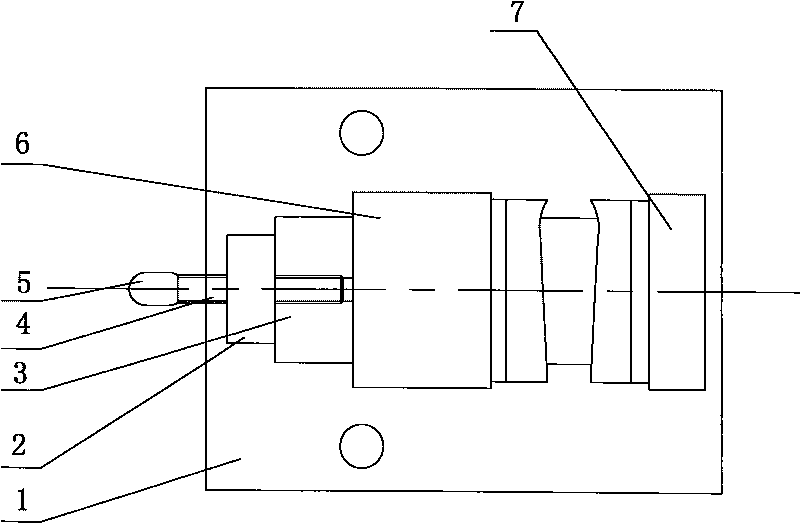

[0009] See attached figure 1 to attach figure 2 As shown, a rocker clamping fixture includes a base 1, a support platform 2 standing on the upper bottom surface of the base 1 and connected to the base 1, and a guide rail is fixedly connected to the support platform 2 3. The fixed collet 7 has a movable collet 6 on the guide rail 3, a threaded rod 4 passes through one end of the support table 2, and is welded together with the rocking bar 5 at one end of the threaded rod 4. One end is rotatably connected to the movable chuck 6 . When the rocker 5 is shaken in a fixed direction, the movable chuck 6 moves closer to the fixed chuck 7, and at this time, the rocker clamping fixture is in a clamping state, and is self-locking through threads; When the rocking bar 5 shakes in another direction, the screw mandrel 4 drives the movable chuck 6 to retreat, and the workpiece is automatically released, and the clamping fixture of the rocking bar is in a relaxed state at this time.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com