Thickened tyre

A technology for tires and tire casings, which is applied to tire parts, transportation and packaging, segmented casings, etc. It can solve the problems of punctured tires and inability to travel, and achieve the effects of preventing tire blowouts, simple structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

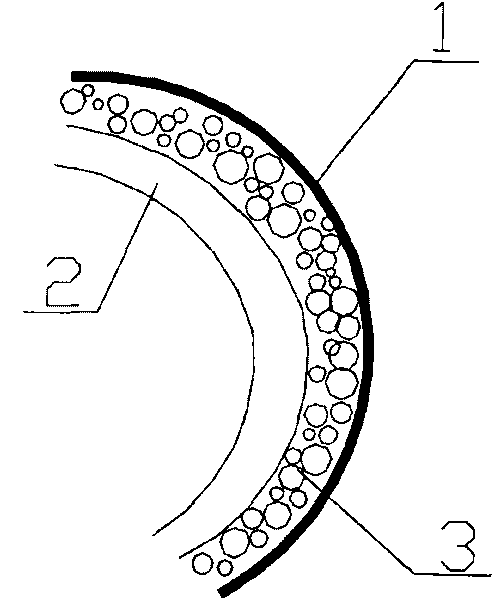

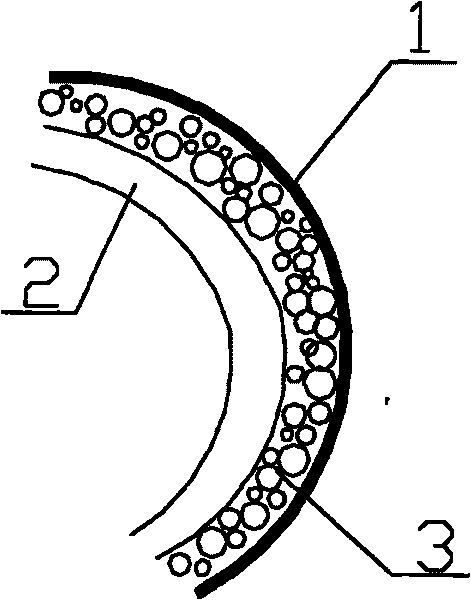

[0010] Such as figure 1 As shown, this thickened tire includes a cover tire 1 and an inflatable inner tube 2, and is characterized in that: a layer of solid sponge 3 is arranged between the described cover tire 1 and the inflatable inner tube 2, and the thickness of the sponge 3 is greater than the length of a general nail .

[0011] In the process of bicycle running, the outer tire and the inner tire are often punctured at the same time due to sharp substances, but the present invention adds a layer of solid sponge 3 between the inner tire 2 and the outer tire 1, which visually increases the distance between the outer tire 1 and the inner tire 2. The gap between makes the sharp material can not directly touch the inner tube 2 due to the blocking of the sponge layer 3 when the cover tire 1 is punctured, thereby ensuring driving safety.

[0012] The invention is simple in structure and reasonable in design, prevents the phenomenon of tire blowout caused by sharp substances in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com