Rapid whole vehicle performance test method based on automobile informatization system

A test method and automobile technology, which is applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems that affect the average size of vehicle performance index detection, inaccurate measurement accuracy, etc., and achieve safety performance improvement, Avoid the effect of tire blowout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention provides a technical solution: a rapid vehicle performance testing method based on an automobile information system, comprising the following steps:

[0025] S1: Clean the exterior of the vehicle first, then pick out the stones trapped in the tread pattern of the car, and at the same time perform the height detection operation of the engine oil level of the car engine bottom case to make it within the allowable height range, and at the same time check the automatic transmission (Hydraulic torque converter) liquid level is checked to make it within the allowable height range.

[0026] S2: Then check the engine cooling system to ensure that the cooling system can work normally.

[0027] S3: Then maintain the car engine and chassis to ensure that the oil supply system and ignition system are in the best working condition.

[0028] S4: Then detect the tire pressure of the four tires of the car to be tested. When the tire pressure is lower than the nor...

Embodiment 2

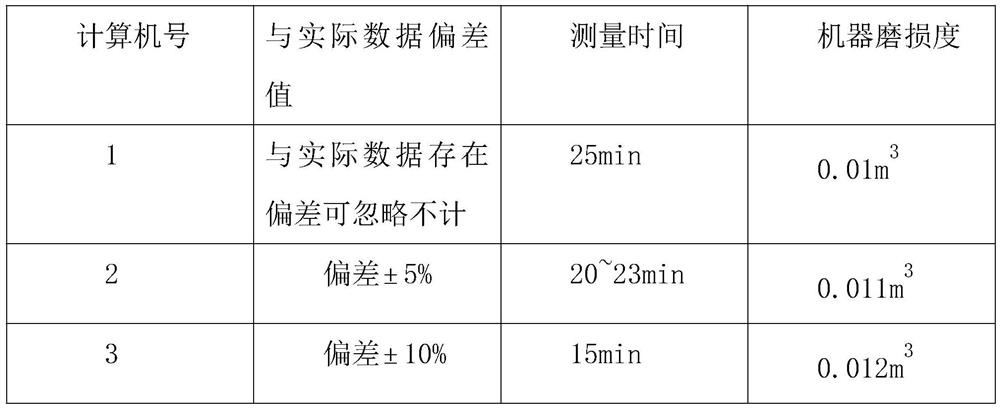

[0036] The specific difference from Embodiment 1 is: in S4, only the tire pressure of each tire of the automobile is measured, and the average friction coefficient of the driving wheel is not measured, so that the actual operation is carried out and the calculated result is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com