Luminous module

A technology of light-emitting modules and light-emitting diodes, which is applied in the direction of light sources, electric light sources, point light sources, etc., can solve the problems of high cost and unfavorable mass production, and achieve the effects of improving production efficiency, saving manufacturing costs, and saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

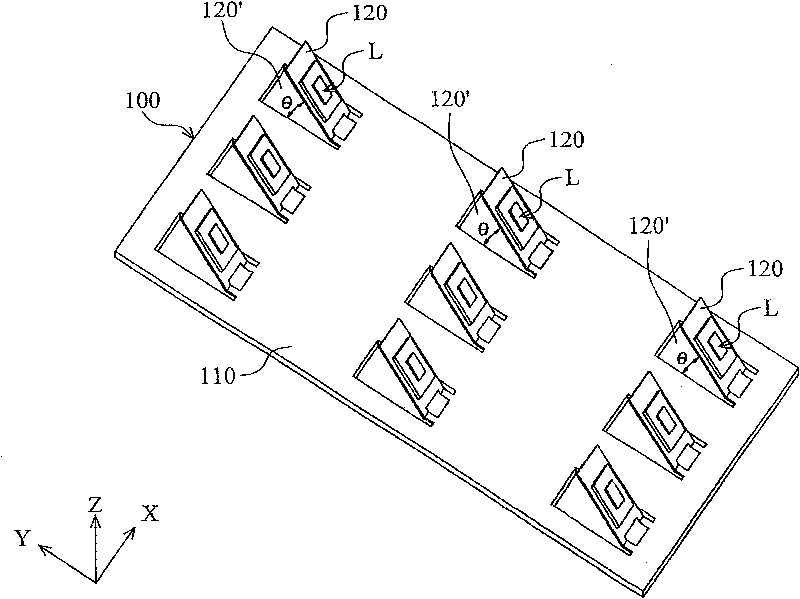

[0036] see figure 2 , the light emitting module of an embodiment of the present invention mainly includes a body 100 and a plurality of light emitting diodes L, the body 100 has an outer surface 110, a plurality of openings 120' and a plurality of bending structures 120, wherein the outer surfaces 110 are substantially parallel In the XY plane, the positions of the bending structures 120 correspond to the aforementioned openings 120 ′ respectively. It should be understood that the aforementioned bending structure 120 protrudes from the outer surface 110 toward the Z-axis direction, wherein an included angle θ is formed between the bending structure 120 and the outer surface 110 , and 0°<θ<180°.

[0037] like figure 2 As shown, the aforementioned light-emitting diodes L are respectively installed on the bending portion 120, wherein by forming an angle θ between the bending portion 120 and the outer surface 110, a light-emitting module with a three-dimensional shape can be fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com