Error automatic warning method for self-defined error range system of metering equipment

A technology of measurement equipment and error range, which is applied in the field of error control of measurement equipment, can solve problems such as the inability to strictly control the measurement results of measurement equipment, and achieve the effect of strict control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

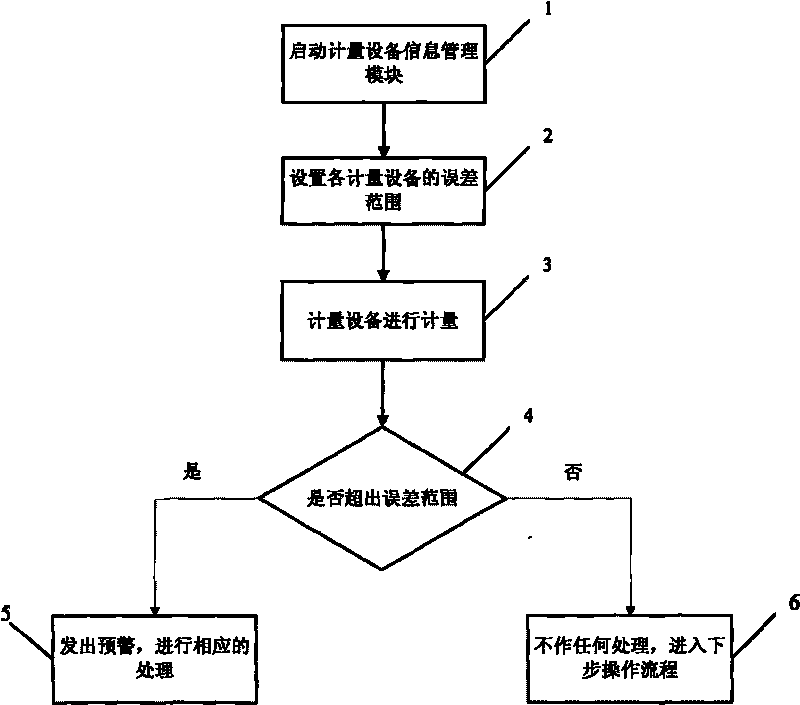

[0016] Such as figure 1 As shown, the error automatic warning method of the measurement equipment custom error range system includes the following steps:

[0017] (1) Start the metering equipment information management module;

[0018] (2) Set the error range of each measuring equipment;

[0019] (3) The measuring equipment performs the measurement and obtains the measurement result;

[0020] (4) Detect whether the measurement result exceeds the error range according to the set error range, if so, then perform step (5), if not, then perform step (6);

[0021] (5) Issue an early warning and deal with it accordingly;

[0022] (6) Do not do any processing, and enter the next operation process.

[0023] The measuring equipment includes warehouse measuring equipment, workshop measuring equipment and laboratory measuring equipment.

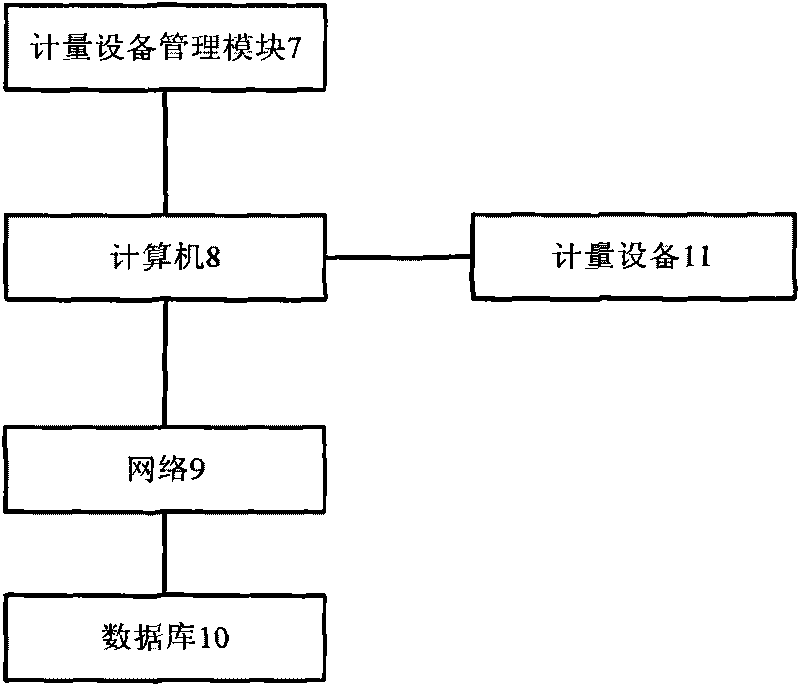

[0024] Such as figure 2 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com