Constant current source

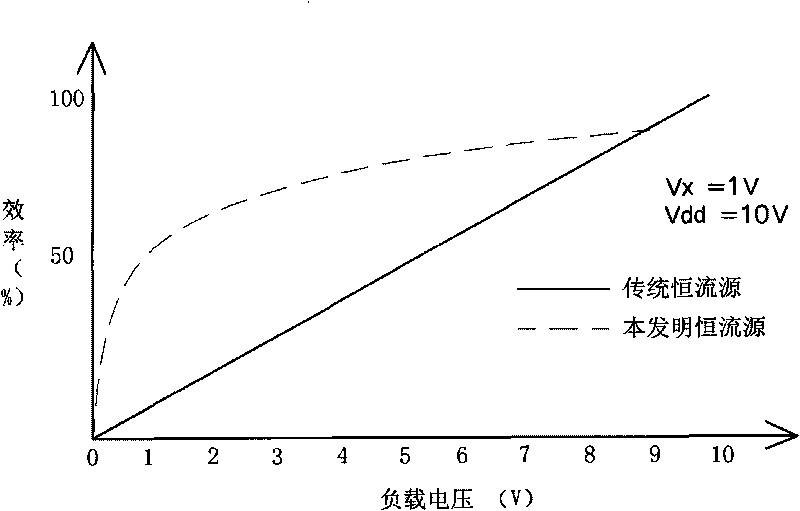

A technology of constant current source and voltage, which is applied in the direction of instruments, control/regulation systems, and adjustment of electrical variables, etc. It can solve the problems of increasing the complexity of system thermal design, low efficiency of power utilization, and poor flexibility of use, so as to improve flexibility and power utilization efficiency, reducing the effect of thermal design complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

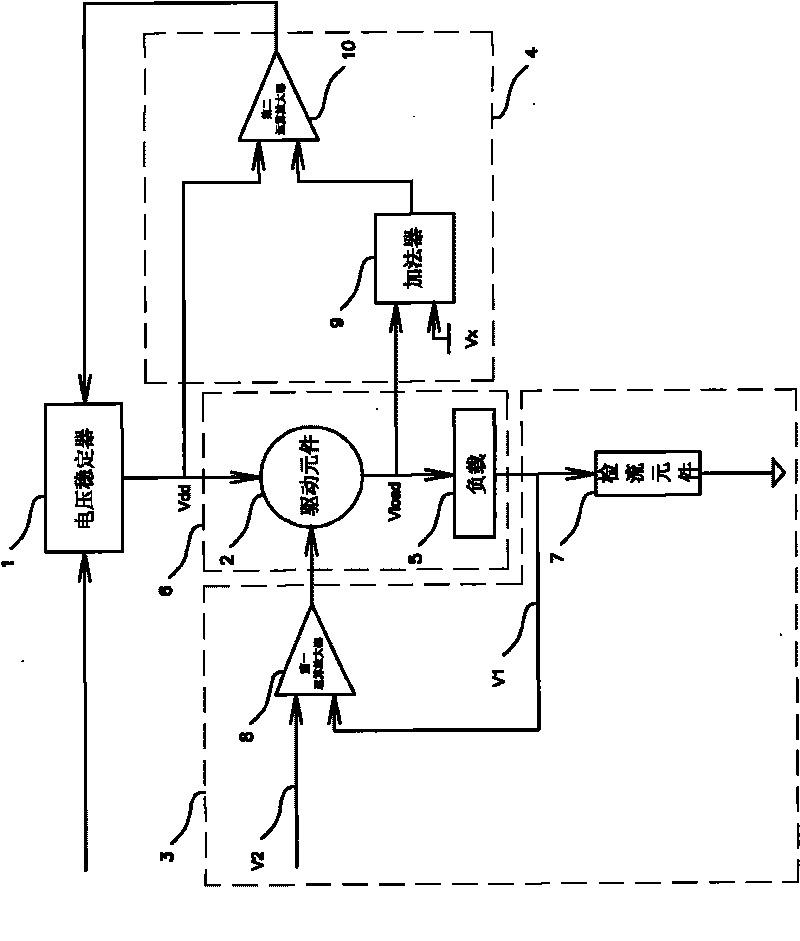

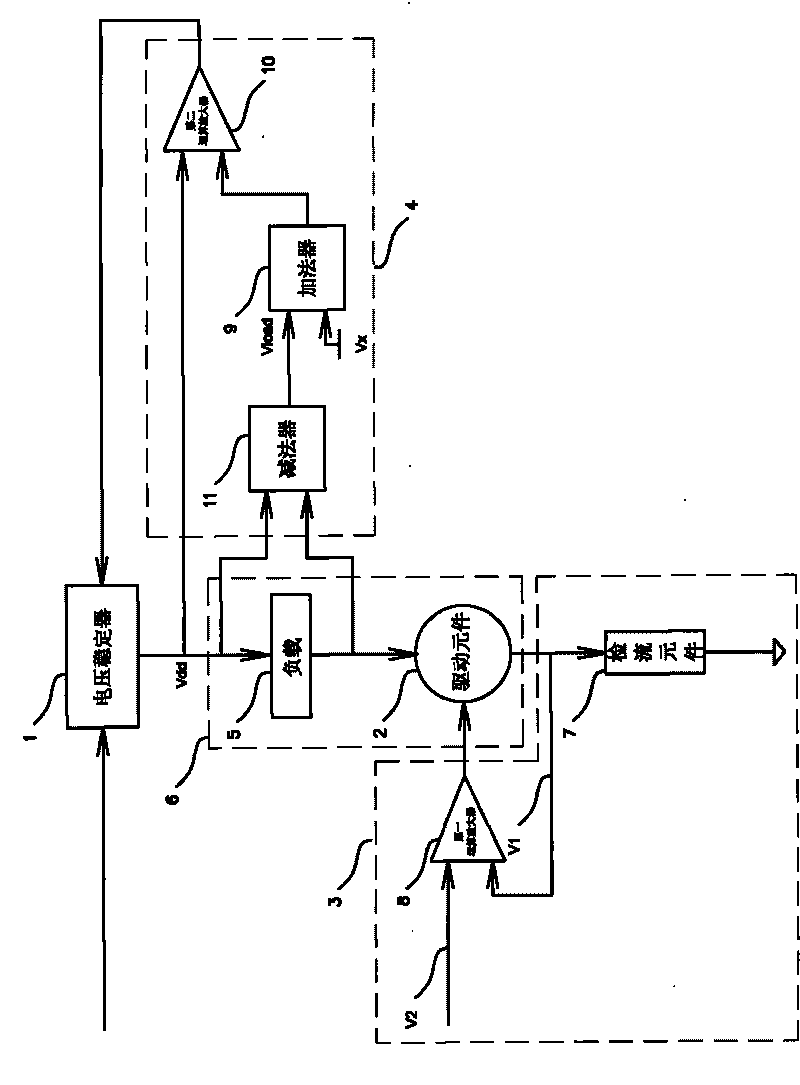

[0019] Such as figure 1 , 2 As shown, the constant current source of the present invention is composed of a voltage stabilizer 1 , a driving element 2 , a constant current feedback unit 3 and a load adaptive feedback unit 4 . The voltage stabilizer 1 is a DC conversion module or a DC conversion chip with an output voltage adjustable function, and the driving element 2 is a bipolar transistor or a MOSFET. The voltage stabilizer 1 provides the driving voltage Vdd to the series circuit 6 composed of the driving element 2 and the load 5, the constant current feedback unit 3 detects the load current, and provides a driving signal to the driving element 2 according to the detection result, and adjusts the output signal of the driving element 2, The adaptive feedback unit 4 detects the load voltage, and provides an adjustment signal to the voltage stabilizer 1 according to the detection result to adjust the output signal of the voltage stabilizer 1 .

[0020] Such as figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com