10kv indoor metal armoring draw out switchgear check trolley

A metal armoring and switchgear technology, applied in the direction of pull-out switchgear, switchgear, electrical components, etc., can solve the problem of short-circuit equipment, severe heat generation, and the inability to accurately judge the depth of a contact insertion. The circuit breaker trolley valve is opened and other problems, to prevent poor contact and ensure full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

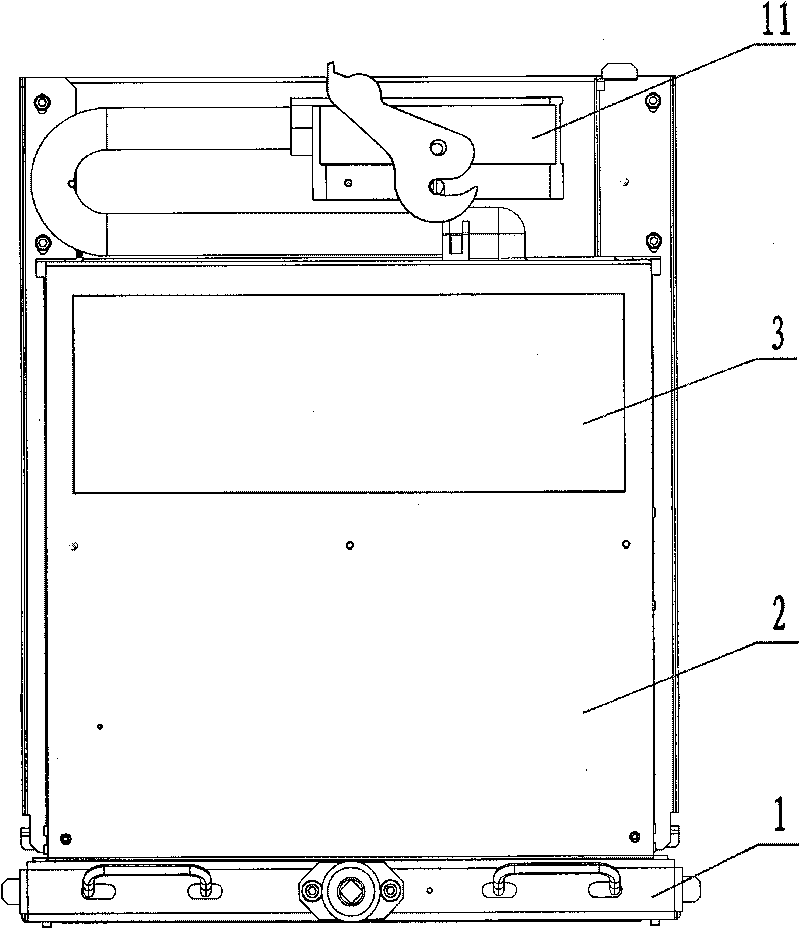

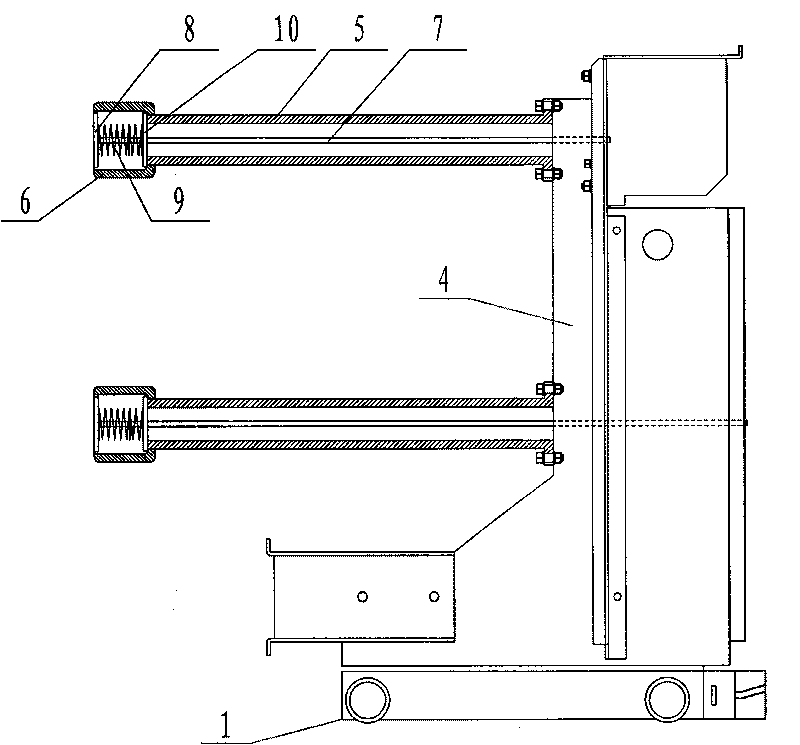

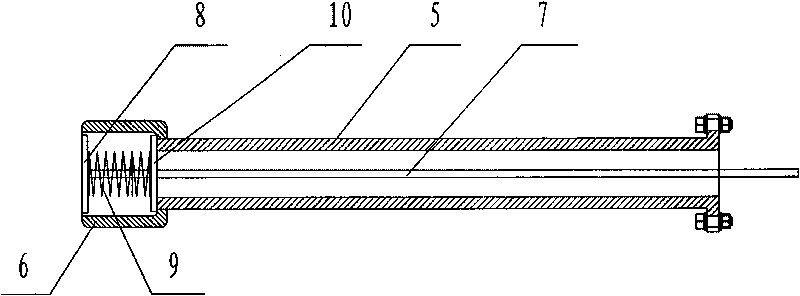

[0014] refer to figure 1 , figure 2 , image 3 , a 10kV indoor metal armored draw-out type switchgear inspection trolley disclosed by the present invention includes a chassis vehicle 1 on which a frame 2 is installed, an observation window 3 is arranged on the frame 2, and the rear side of the frame 2 is installed There is a simulated circuit breaker 4; a contact arm 5 is installed on the simulated circuit breaker 4, and a contact 6 is installed at the end of the contact arm 5. The structure of the chassis car used in the present invention is consistent with the chassis structure of the actual operating circuit breaker trolley.

[0015] The simulated circuit breaker of the present invention has the same structure as the actual circuit breaker, and the structure, size and installation position of the present invention are completely consistent with the actual operating circuit breaker trolley, so that the present invention can replace the actual operating circuit breaker trol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com