Pin breakage prevention type multi-contact socket

A multi-contact, socket technology, applied in contact parts, parts of connecting devices, parts of electrical measuring instruments, etc., can solve problems such as poor contact, damage, and cannot prevent probe damage, and prevent bending or damage. , The effect of preventing poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

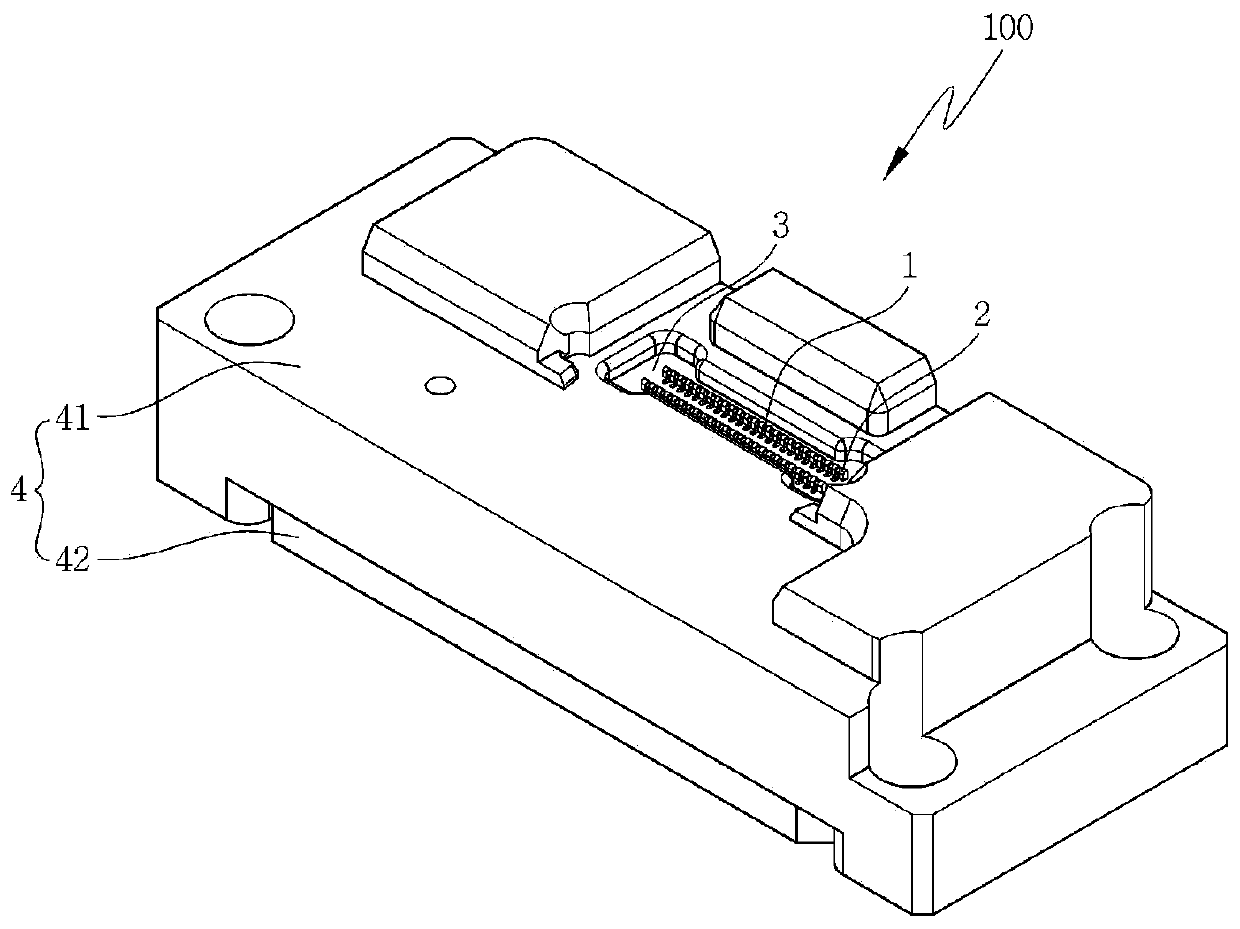

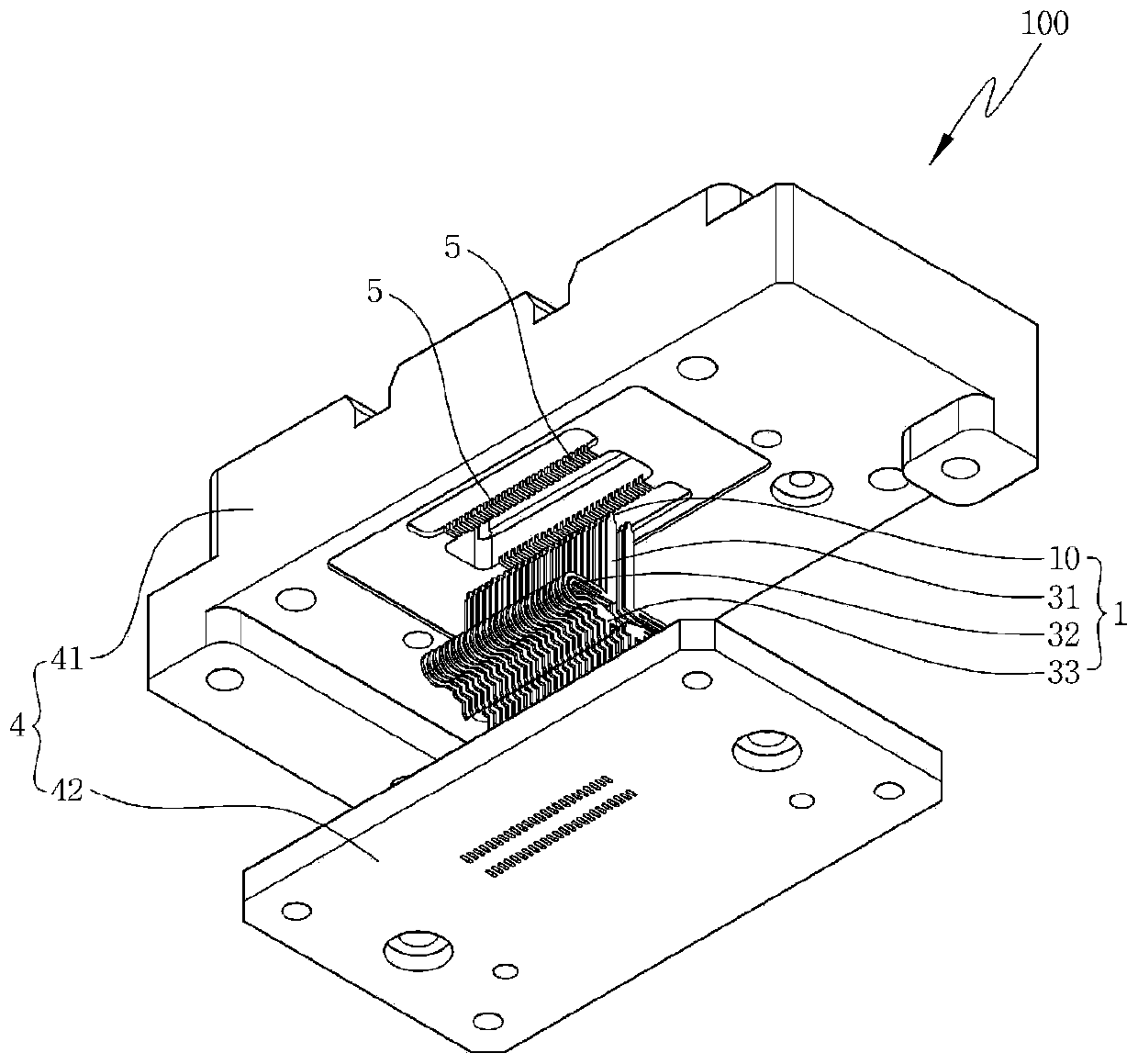

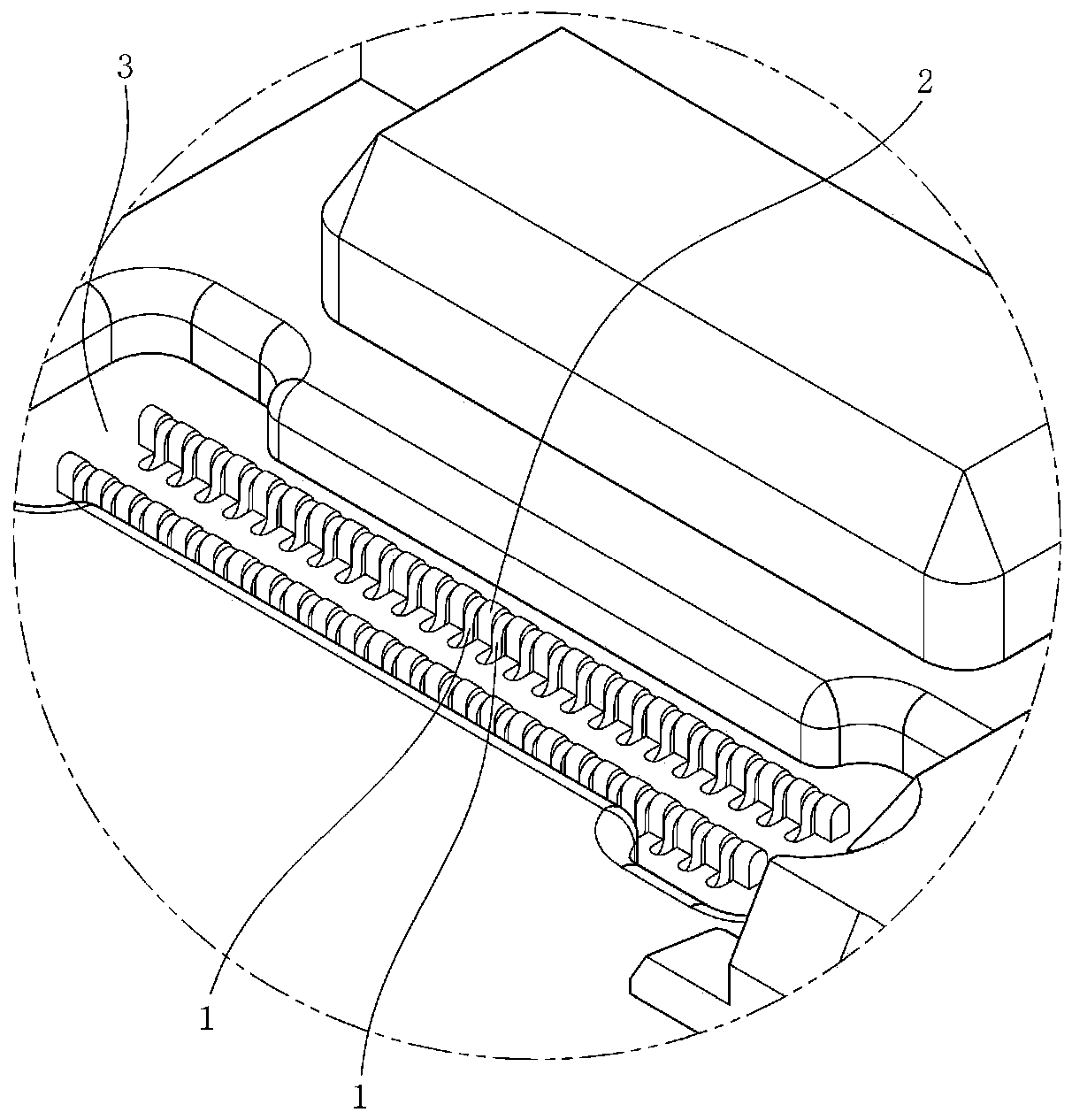

[0064] figure 1 is a perspective view of a pin damage-resistant multi-contact socket according to the present invention, figure 2 is an exploded perspective view of a multi-contact socket that prevents damage to pins according to the present invention, image 3 is an enlarged view of the first embodiment of the pin damage-resistant multi-contact socket according to the present invention, Figure 4 is an enlarged view of a second embodiment of the pin damage-proof multi-contact socket according to the present invention, Figure 5 is an exploded view of a third embodiment of the pin damage-resistant multi-contact socket according to the present invention, Figure 6 is an enlarged view of the third embodiment of the pin damage-proof multi-contact socket according to the present invention, Figure 7 to Figure 9 is a diagram of the connection of the contact terminals to the connection pins of the multi-contact socket for preventing pin damage according to the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com