Method for hoisting by lifting belt vertically

A hoisting method and vertical hoisting technology, which are used in hoisting devices, transportation and packaging, load hoisting components, etc., can solve the problems of high construction cost, difficult to change direction, and difficulty in the head wheel penetrating the belt, and can solve the problem of installation. The effect of working, avoiding use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

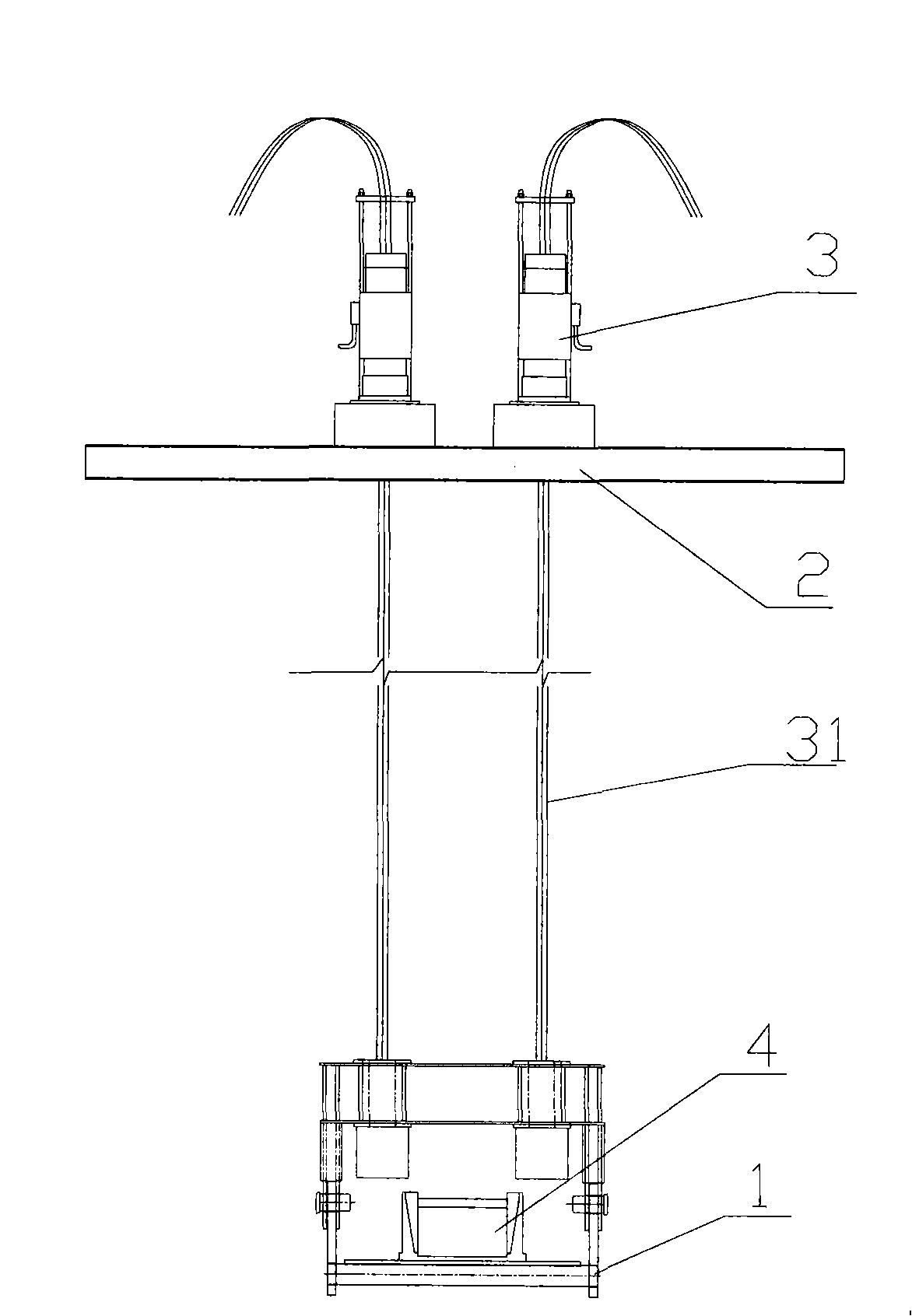

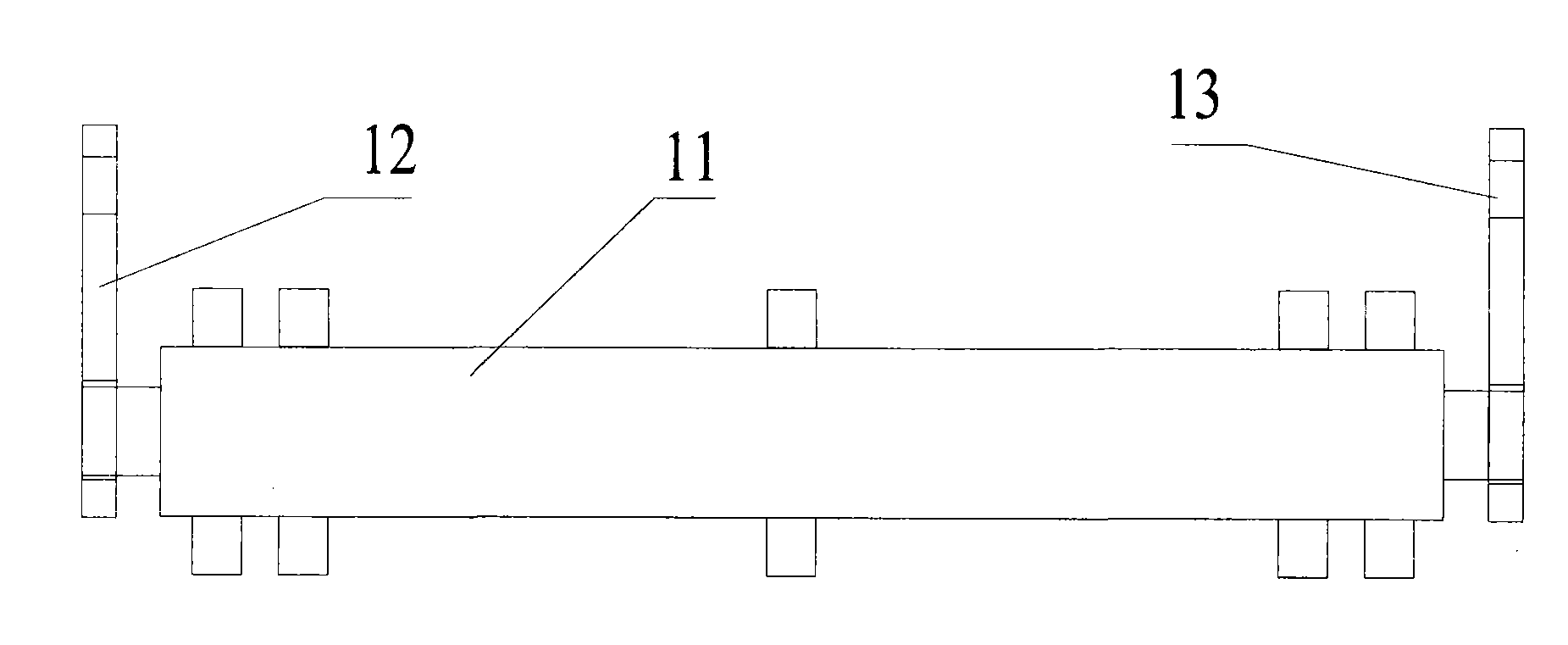

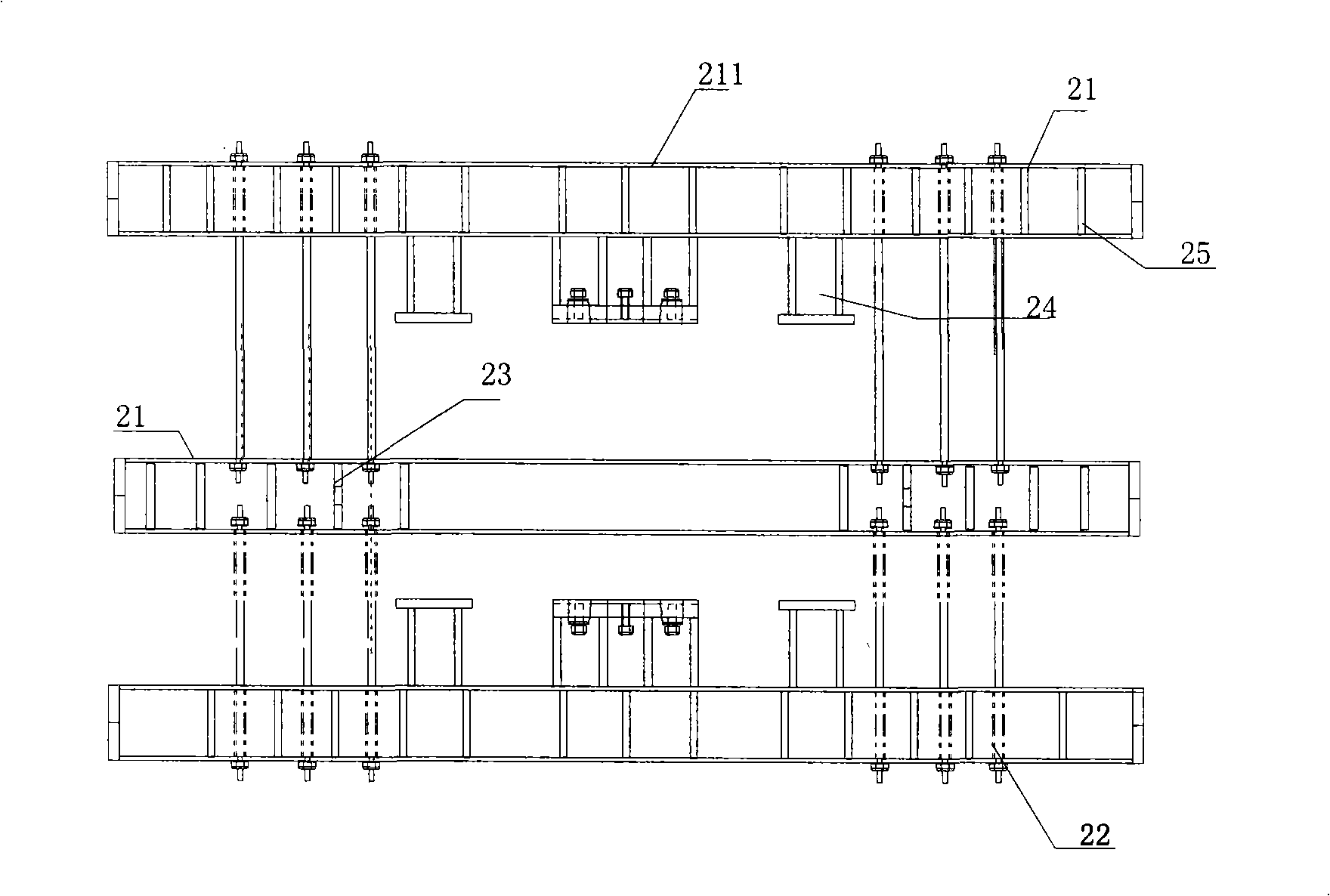

[0027] Such as figure 1 As shown, a vertical lifting belt hoisting method mainly includes a spreader 1, two sets of clamps 2 and a hydraulic lifting device 3 and includes the following steps:

[0028] Step 1, install the hydraulic lifting device 3 on the uppermost platform, pass the operation and debugging, and place the fixture 2 on the middle and upper platform;

[0029] Step 2, the spreader 1 is inserted into the belt 4 placed on the ground, and the steel strand 31 of the hydraulic lifting device 3 is connected to the spreader 1;

[0030] Step 3, the hydraulic lifting device 3 is lifted, the belt 4 is pulled to the top, and the belt 4 is fixed with the clamp 2;

[0031] Step 4, temporarily use the guide chain to pull the spreader, the hydraulic lifting device 3 is lowered, the steel strand 31 is connected to the fixture, and the lifting is continued;

[0032] Step five, move the spreader 1 horizontally, and put the belt pulley through;

[0033] Step 6, the hydraulic lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com