Construction method of section-steel triaxial soil-cement mixing pile

A technology of cement-soil mixing pile and construction method, which is applied to sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of long time of re-mixing process, difficulty in pre-mixing sinking, etc. Solve the effect of too long process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

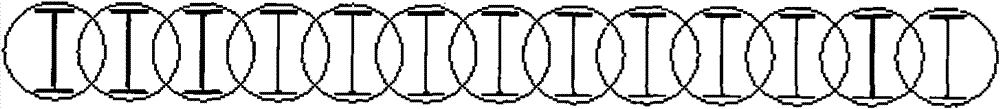

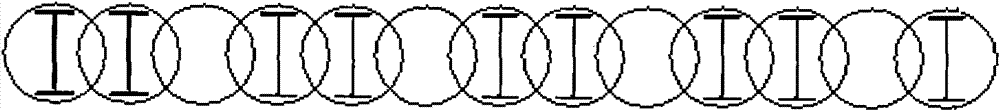

[0032] The steel cement-soil mixing pile of the present invention uses a three-axis long screw drilling machine to drill holes in the soil, cut the soil, air jets when drilling, spray cement slurry, and spray cement slurry when drilling to achieve repeated mixing with the foundation. Each construction unit adopts overlapping construction, and inserts section steel into the mixing pile before the cement soil is hardened; thus forming a composite pile body that not only stops water but also functions as an enclosure structure.

[0033] Generally, the ZKD85-3 multi-axis drilling machine is mainly used in the construction.

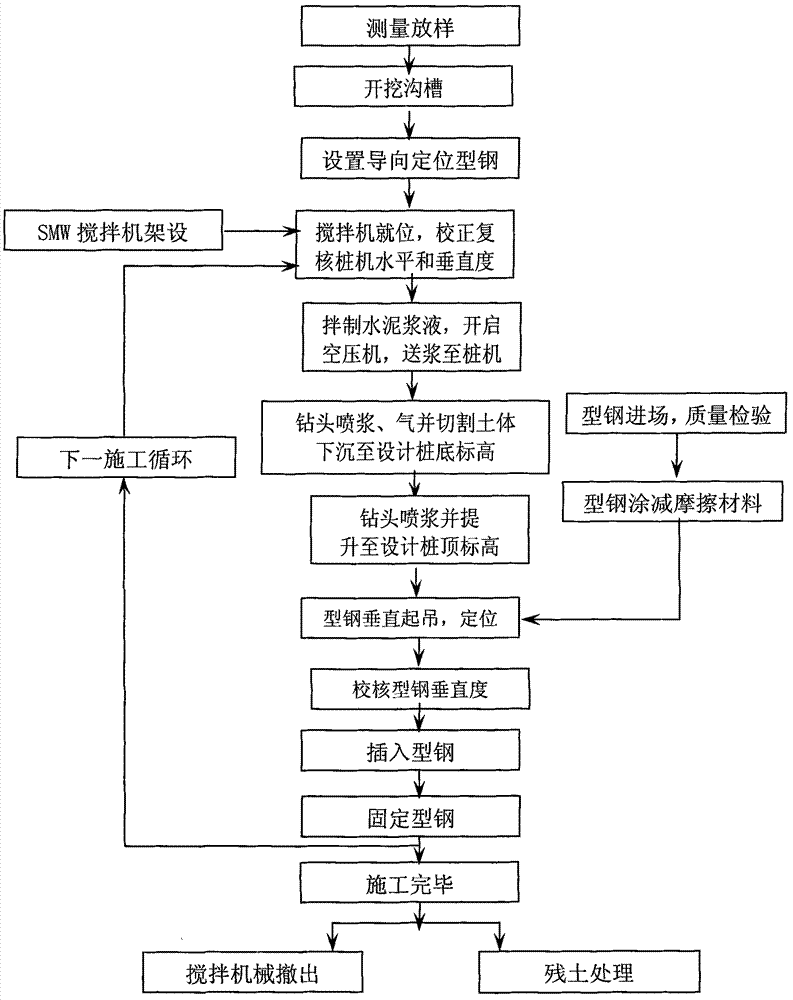

[0034] The process of the construction method of the present invention such as flow figure 1 As shown, according to the measurement results, a guide trench was dug at the position of the three-axis mixing pile to be constructed. The width of the guide trench was the pile diameter plus 400 mm. At the same time, underground obstacles should be removed, and the excess ...

Embodiment 2

[0055] The steel cement-soil mixing pile of the present invention uses a three-axis long screw drilling machine to drill holes in the soil, cut the soil, air jets when drilling, spray cement slurry, and spray cement slurry when drilling to achieve repeated mixing with the foundation. Each construction unit adopts overlapping construction, and inserts section steel into the mixing pile before the cement soil is hardened; thus forming a composite pile body that not only stops water but also functions as an enclosure structure.

[0056] Generally, the ZKD85-3 multi-axis drilling machine is mainly used in construction.

[0057] The process of the construction method of the present invention such as flow figure 1 As shown, according to the measurement results, a guide trench was dug at the position of the three-axis mixing pile to be constructed. The width of the guide trench was the pile diameter plus 400 mm. At the same time, underground obstacles should be removed, and the excess soil...

Embodiment 3

[0076] The steel cement-soil mixing pile of the present invention uses a three-axis long screw drilling machine to drill holes in the soil, cut the soil, spray jets when drilling, spray cement slurry, and spray cement slurry when drilling to achieve repeated mixing with the foundation. Each construction unit adopts overlapping construction, and inserts section steel into the mixing pile before the cement soil is hardened; thus forming a composite pile body that not only stops water but also functions as an enclosure structure.

[0077] Generally, the ZKD85-3 multi-axis drilling machine is mainly used in the construction.

[0078] The process of the construction method of the present invention such as flow figure 1 As shown, according to the measurement results, a guide trench was dug at the position of the three-axis mixing pile to be constructed. The width of the guide trench was the pile diameter plus 400 mm. At the same time, underground obstacles should be removed, and the exces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com