Retractable and adjustable U-shaped support arm structure for automobile chassis suspension wheel

A technology of automobile chassis and suspension, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problem that the support arm structure cannot meet the adjustment requirements, and achieve easy installation and old car refitting, compact structure, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention can be explained in more detail with reference to the following examples; however, it should be noted that the present invention is not limited to the following examples; the purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

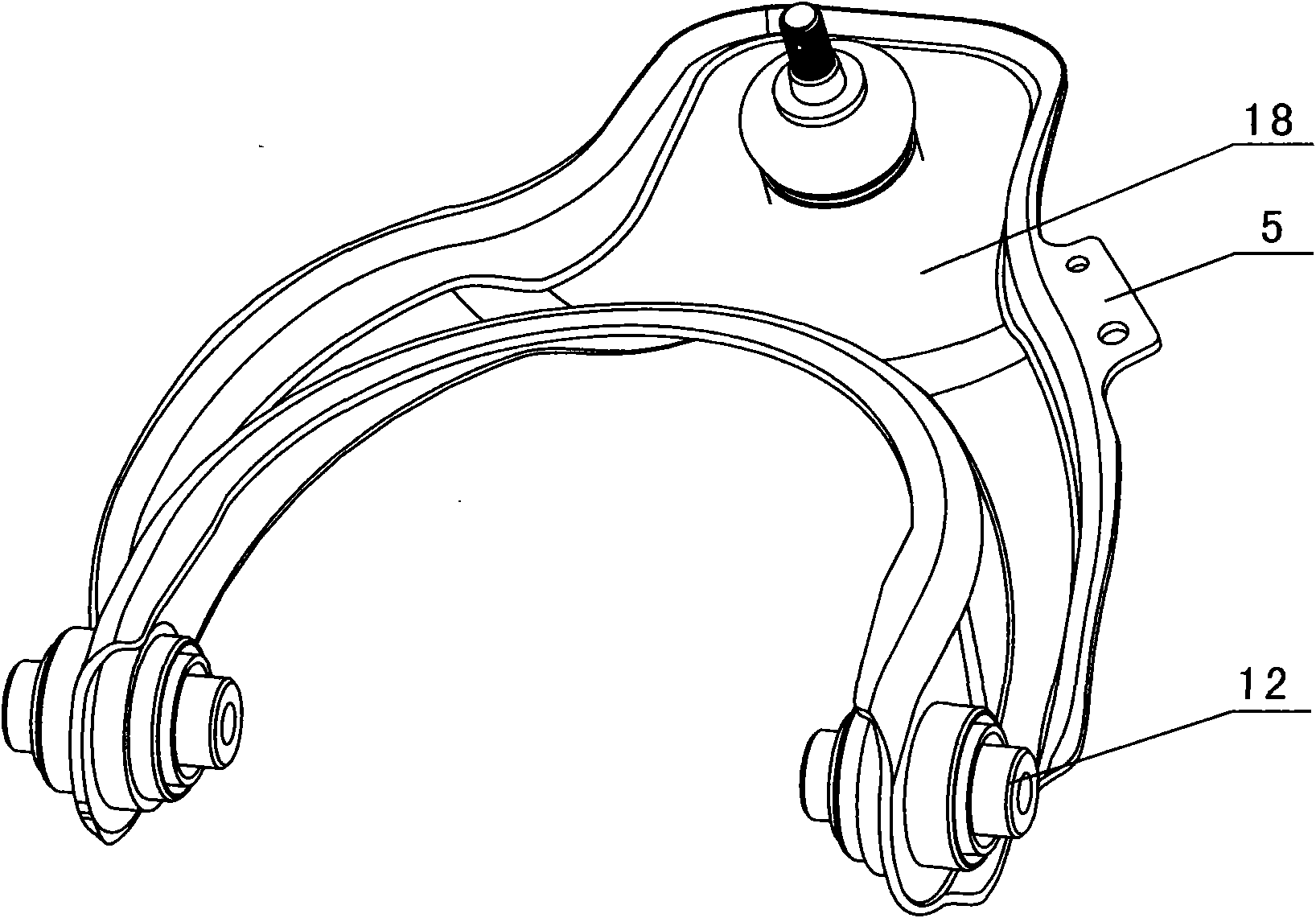

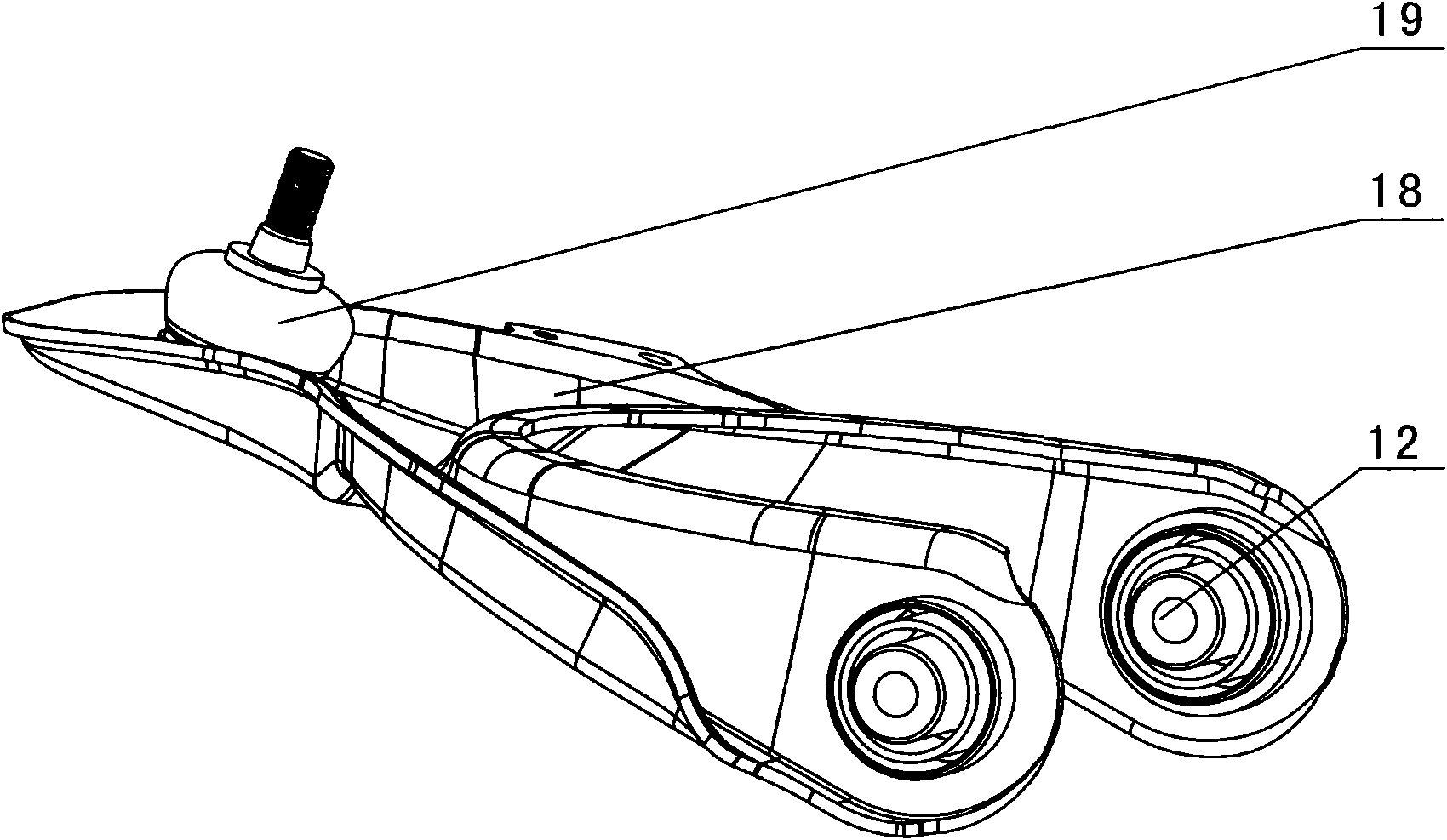

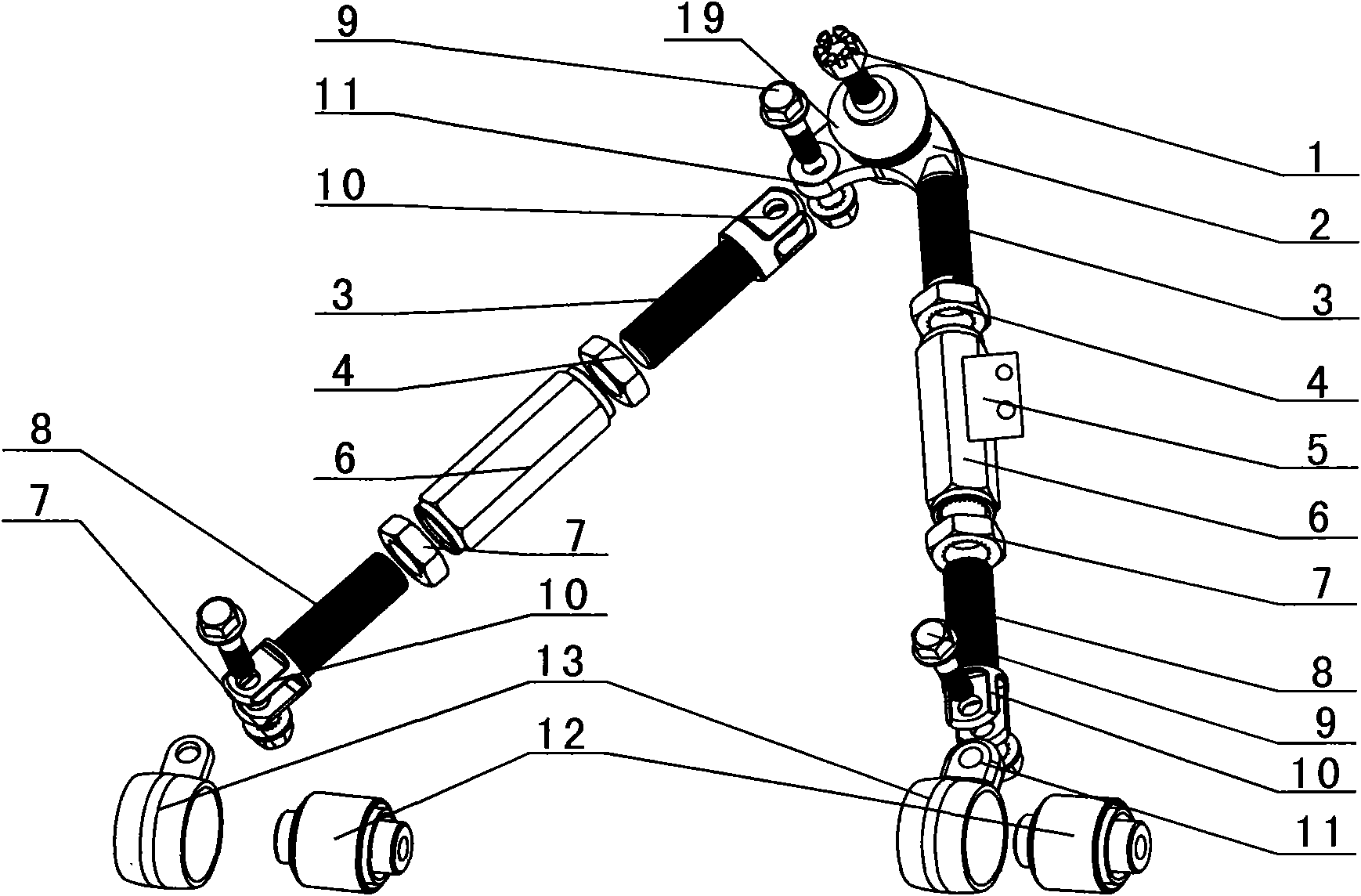

[0035] combine Figure 3 ~ Figure 7 The U-shaped support arm structure for the telescopic adjustment of the automobile chassis suspension wheel includes a support structure for connecting the vehicle hub; a connection structure for adjusting the distance between the "J" seat and two sets of rubber sleeve rings; The rubber sleeve assembly structure connected with the vehicle suspension; the above-mentioned structure for connecting the vehicle hub support, the ball joint assembly 19 and the "J" type seat 2 are integrally structured, and the support assembly (14) is connected to the "J" type seat 2 "Type seat (2) is an integral structure, one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com