Dishwasher

A dishwasher and backwashing technology, applied in dishwasher/washing machine for tableware, washing machine/rinsing machine parts for tableware, cleaning equipment, etc., can solve the problem of increasing water and energy consumption, cleaning cycle limitation, cleaning capacity To achieve the effect of reducing the total water volume, increasing the degree of freedom, and improving sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

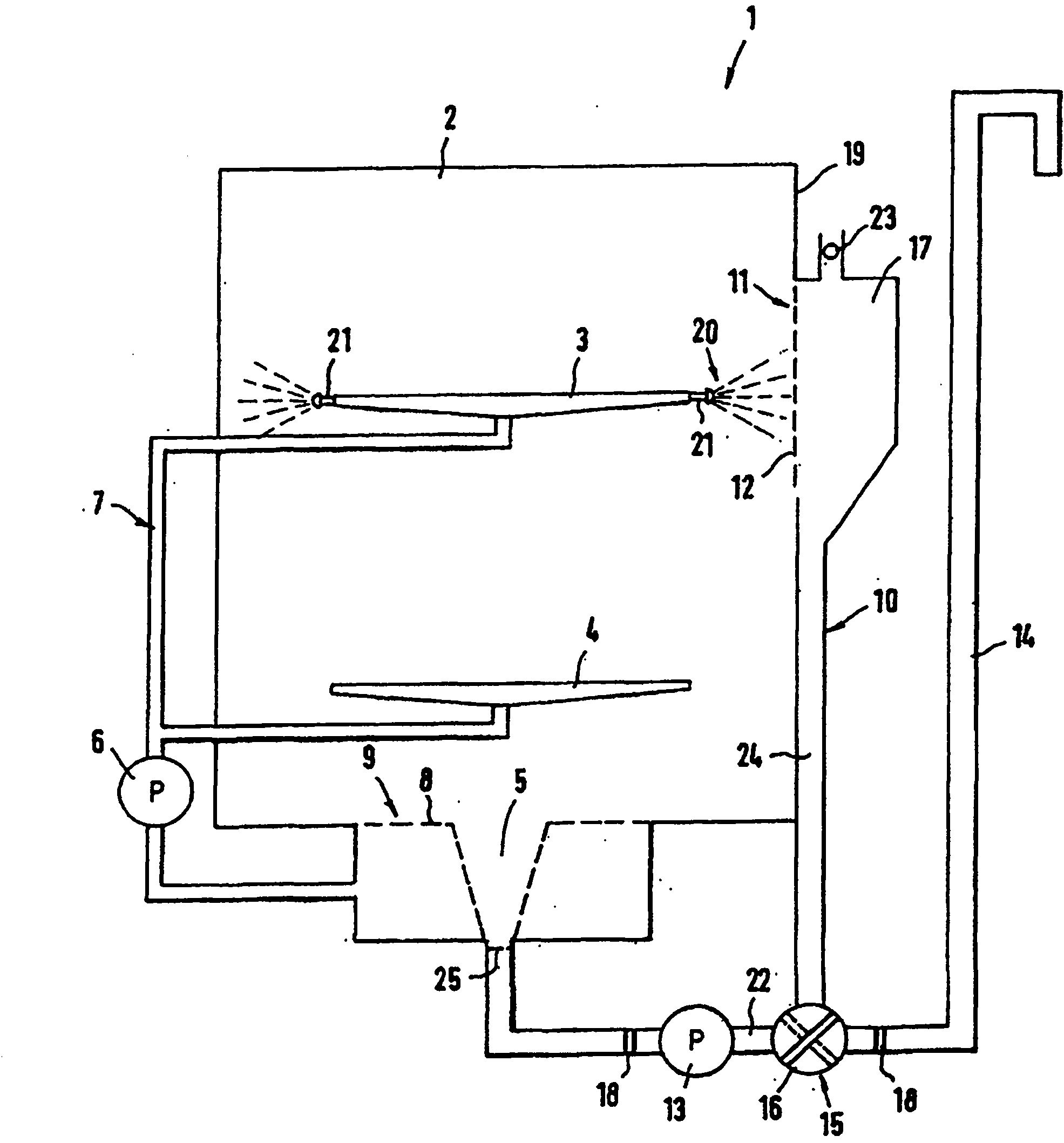

[0042] figure 1 A dishwasher 1 according to a first variant of the first embodiment of the invention is shown. The dishwasher comprises a washing tank 2 in which dirty dishes can be loaded into a dish basket (not shown) to be washed. Two spray arms 3 , 4 are arranged in the washing tank 2 . During operation of the dishwasher 1 , washing liquid is sucked out of the sump 5 by the circulation pump 6 and recirculated into the washing tank 2 via the spray arms 3 , 4 . The cleaning fluid passes through a flat fine filter 8 located in the storage tank 5 while circulating in the first circulation system 7 . In this variant, the fine filter 8 is part of the filter device 9 of the first circulation system 7 . However, the filtration in the first circulation system 7 relies on the actuation of the circulation pump 6 and does not utilize microfiltration. A coarse filter 25 may be provided in the sump 5 from which the washing liquid is drained.

[0043] According to the invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com