Luminaire with limit pre-pressing structure

A lamp and pre-tightening technology, which is applied to the parts of lighting devices, the damage prevention measures of lighting devices, lighting devices, etc., can solve the problems of large installation space, many parts, complicated installation, etc., and achieve the effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

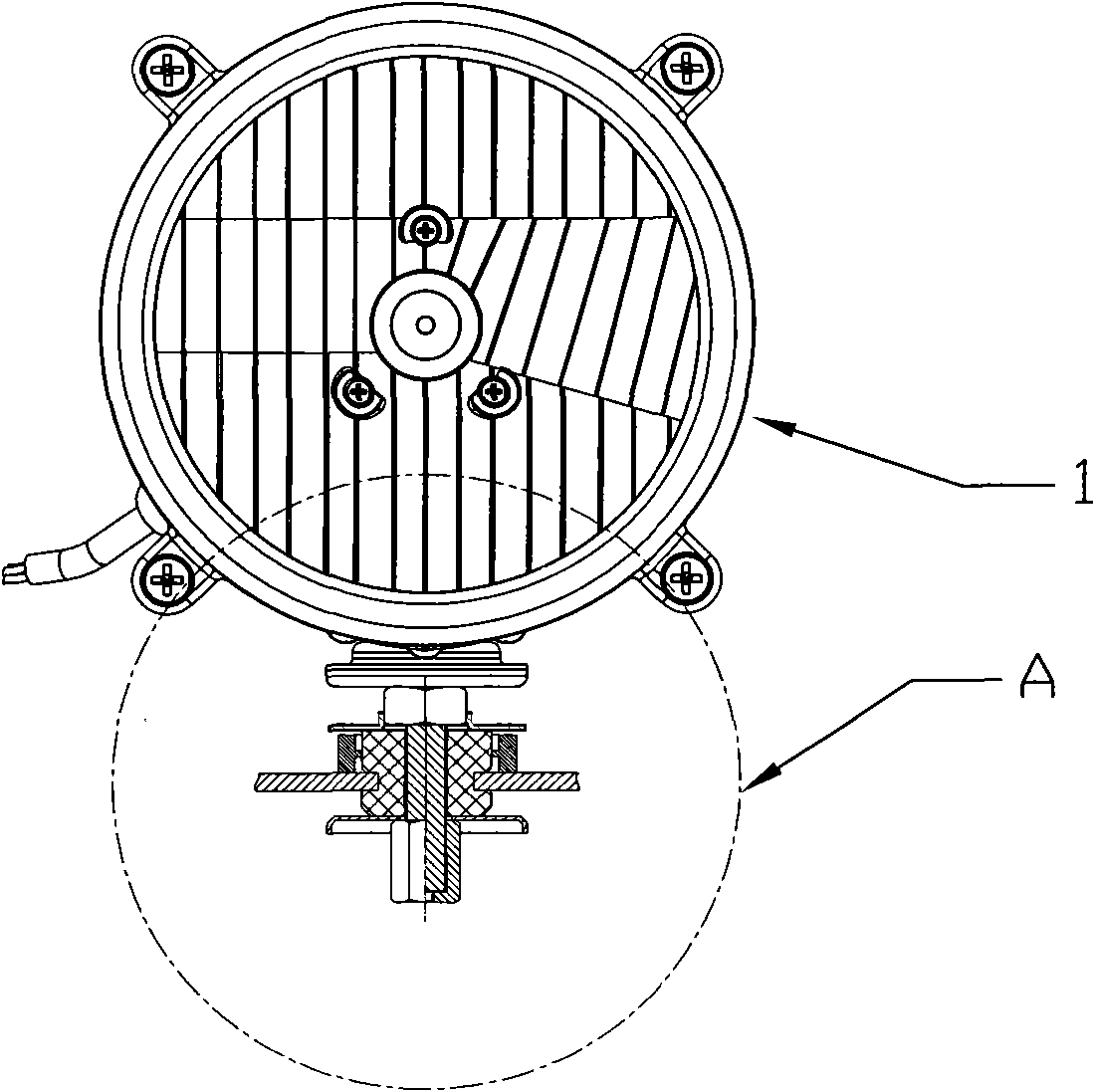

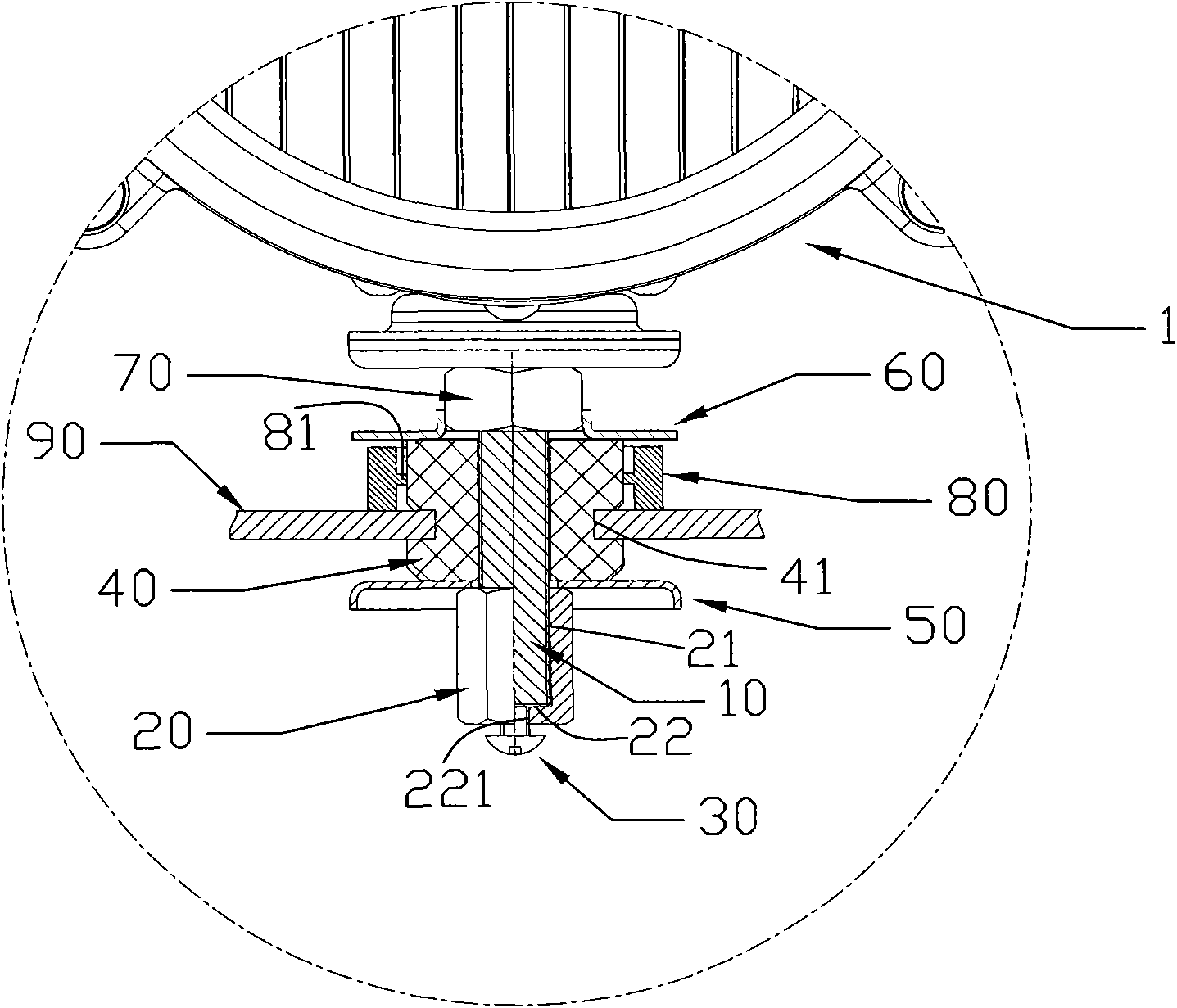

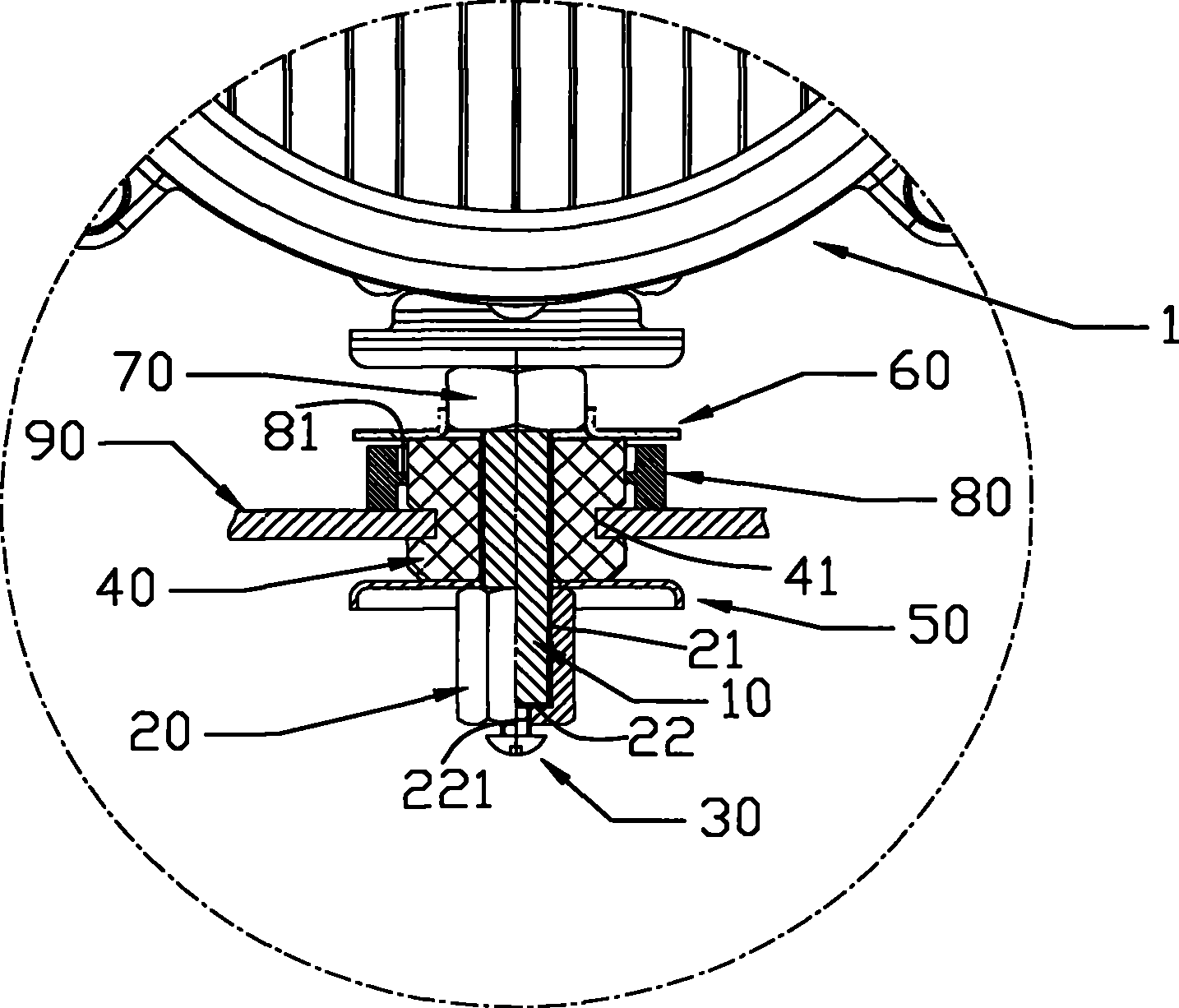

[0018] Such as figure 1 and figure 2 As shown, it is a structural schematic diagram of an embodiment of a lamp with a limit pre-tightening structure in the present invention. The lamp main body 1 is fixedly connected with a fixing screw 10 for fixing the lamp main body 1 on the mounting plate 90. The mounting plate 90 can be The plate structure arranged on the vehicle or other devices has a mounting hole on it, and the fixing screw 10 passes through the mounting hole to fix the lamp main body 1 on the mounting plate.

[0019] In order to prevent the vibration transmitted from the mounting plate 90 from adversely affecting the main body 1 of the lamp, an elastic damping pad 40 is sleeved on the fixing screw 10. The elastic damping pad 40 has a ring groove 41 extending in the circumferential direction, and the ring groove 41 is stuck on the edge of the installation hole of the installation plate 90, which can realize the positioning of the elastic vibration damper 40 and facil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com