Method for removing scale and dirt from surface of steel plate

A technology for steel plates and dirt, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as waste of resources and poor cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

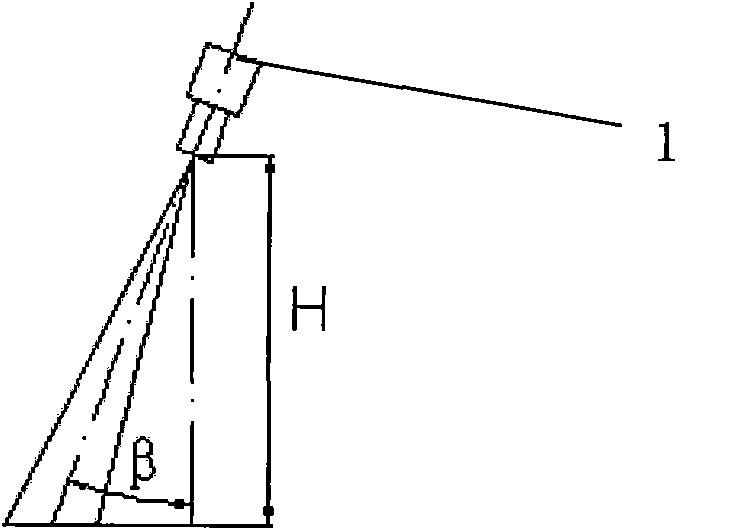

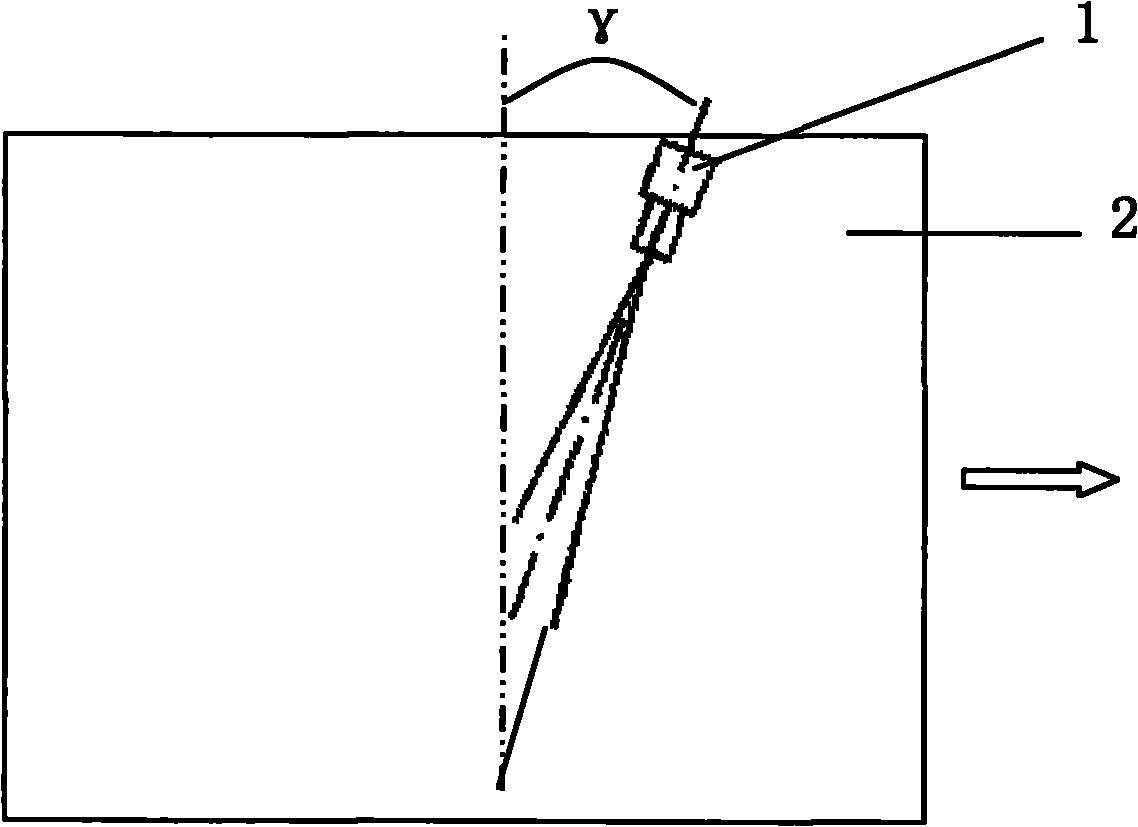

[0011] The method for removing scale and dirt on the surface of the steel plate 2 provided by the present invention is to spray the high-pressure fluid toward the surface of the steel plate 2 by means of the nozzle 1 for spraying the high-pressure fluid, and the high-pressure fluid hits the surface of the steel plate 2 to remove the dirt and scale on the surface of the steel plate 2; Among them: the incident angle β of nozzle 1 is 5°~15°, that is, the angle between the center line of nozzle 1 (the direction of sprayed water flow) and the vertical line on the surface of steel plate 2, see figure 1 . The deflection angle γ of the nozzle 1 is 15°, that is, the angle between the projection line of the centerline of the nozzle 1 on the surface of the steel plate 2 and the horizontal vertical line in the direction of advancement of the steel plate 2, see figure 2 , wherein the direction indicated by the arrow is the advancing direction of the steel plate 2 .

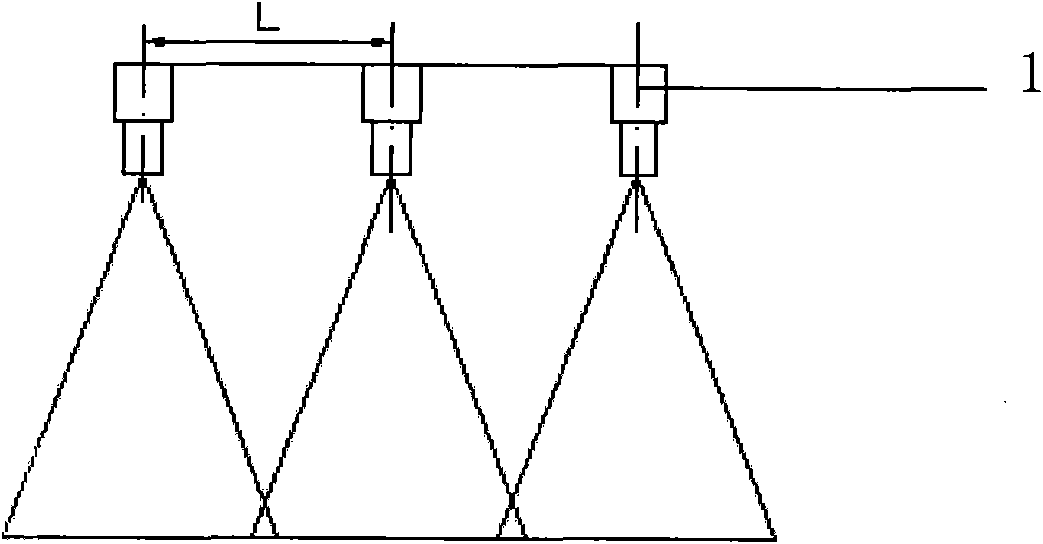

[0012] The arrangeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com