Segmented packing ring

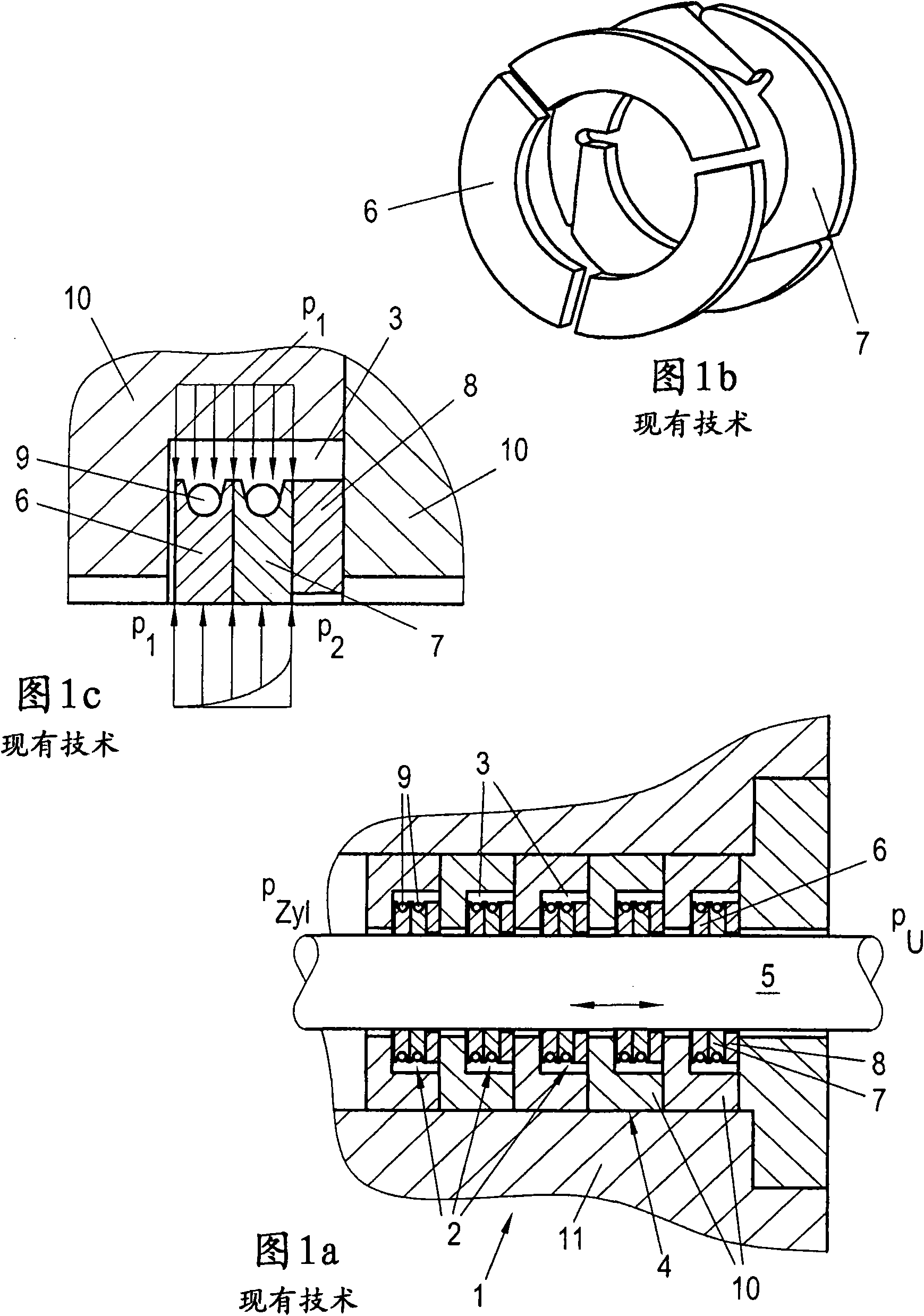

A seal ring, segmented technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of no seal ring service life, replacement and other problems, and achieve the effect of avoiding weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

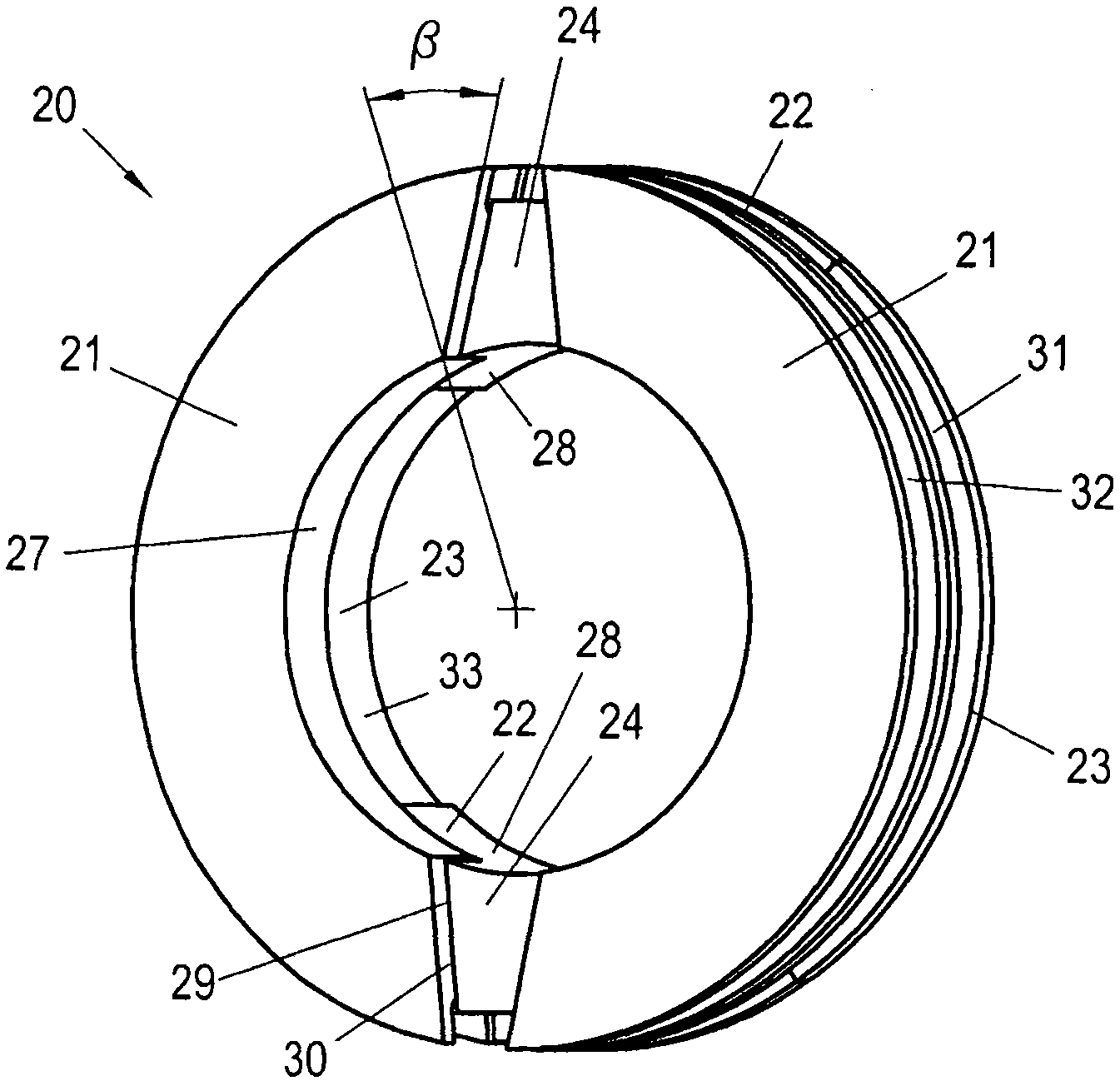

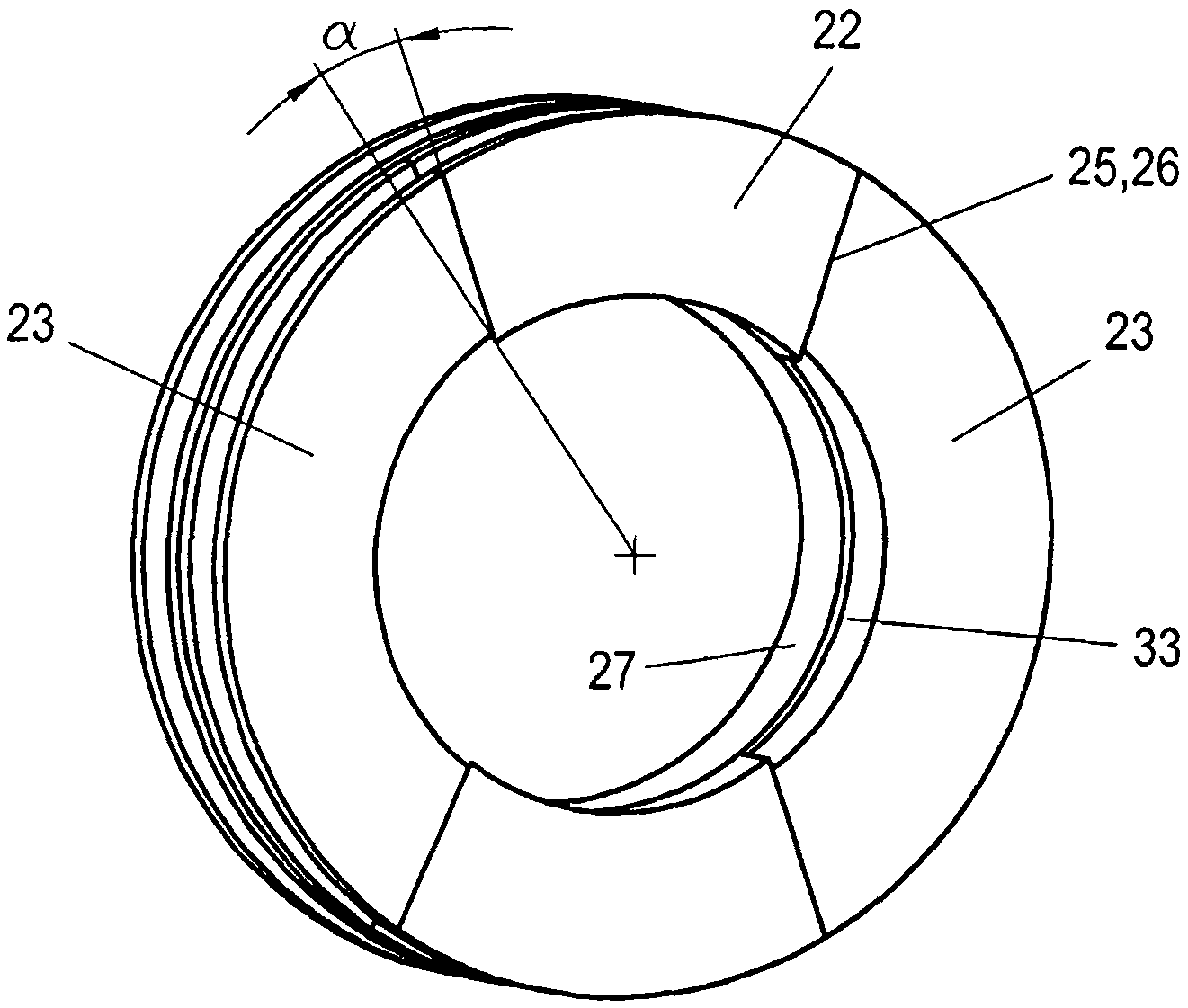

[0020] according to figure 2 with 3 The perspective view of the segmented sealing ring 20 according to the invention shows the sealing ring 20 from two different sides. The sealing ring 20 comprises various ring-segment-shaped segments which together form the sealing ring 20 . The sealing rings here are each formed by two first sealing segments 21 , two second sealing segments 22 and two support segments 23 . However, the sealing ring 20 can also be designed with more than two respective segments 21 , 22 , 23 . The second sealing segments 22 and the support segments 23 bear against one another in the circumferential direction on their circumferential end faces 25 , 26 , wherein the support segments 23 and the second seal segments are arranged alternately against one another. The first section 21 bears axially against the second sealing section 22 and the bearing section 23 . In addition, an axial protrusion 24 is respectively arranged on each second sealing segment 22 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com