Fireproof performance evaluation method of concrete member of water-injection hollow steel pipe and application

A hollow steel tube and concrete technology, which is applied in special data processing applications, building structures, buildings, etc., can solve the problems of inaccurate evaluation, lack of comprehensive evaluation, high cost, etc., and achieve the effect of accurate fire protection evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

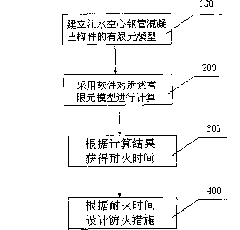

[0031] Such as figure 1 As shown, the specific embodiment of the present invention is: provide a kind of method for evaluating the fire performance of water-injected hollow concrete filled steel tube member, comprising the steps:

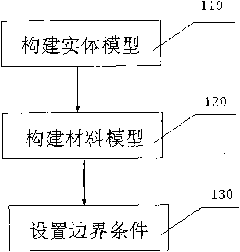

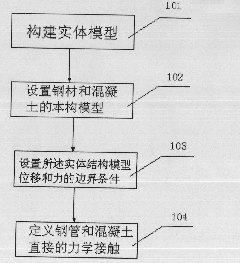

[0032] Step 100: Establish the finite element model of the water-injected hollow concrete-filled steel tube member, that is, respectively establish the finite element model of the temperature field and the mechanical field of the water-injected hollow concrete-filled steel tube member, and the temperature field is finite according to heat transfer and finite element theory. An element model, the mechanical field establishes a finite element model of the mechanical field according to solid mechanics theory and finite element theory. In a specific step, the temperature field establishes a temperature field finite element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com