Vehicle controller and control method

一种车辆控制器、车辆控制的技术,应用在传动装置控制、带有齿的元件、皮带/链条/齿轮等方向,达到缩短时间、抑制冲击的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

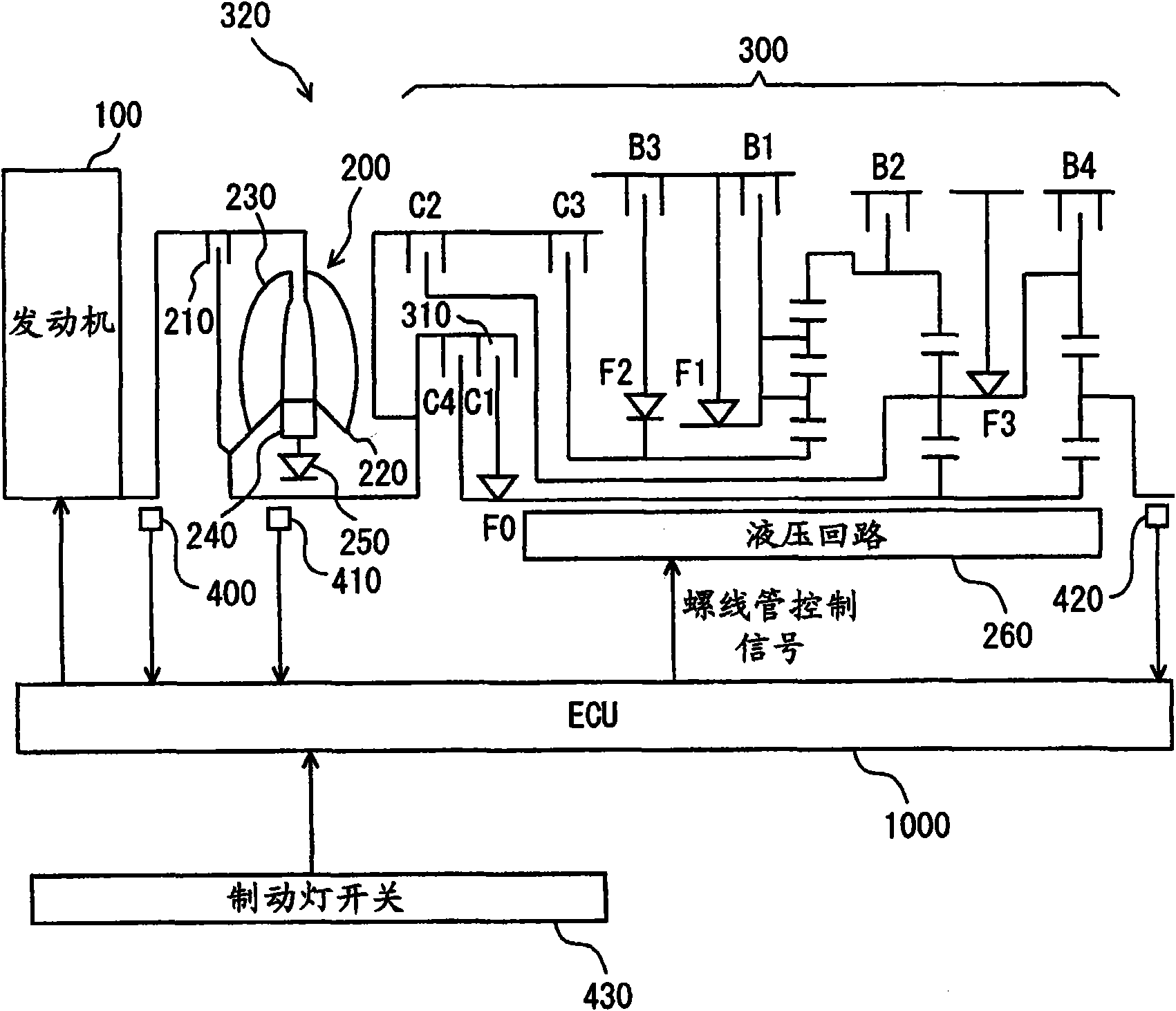

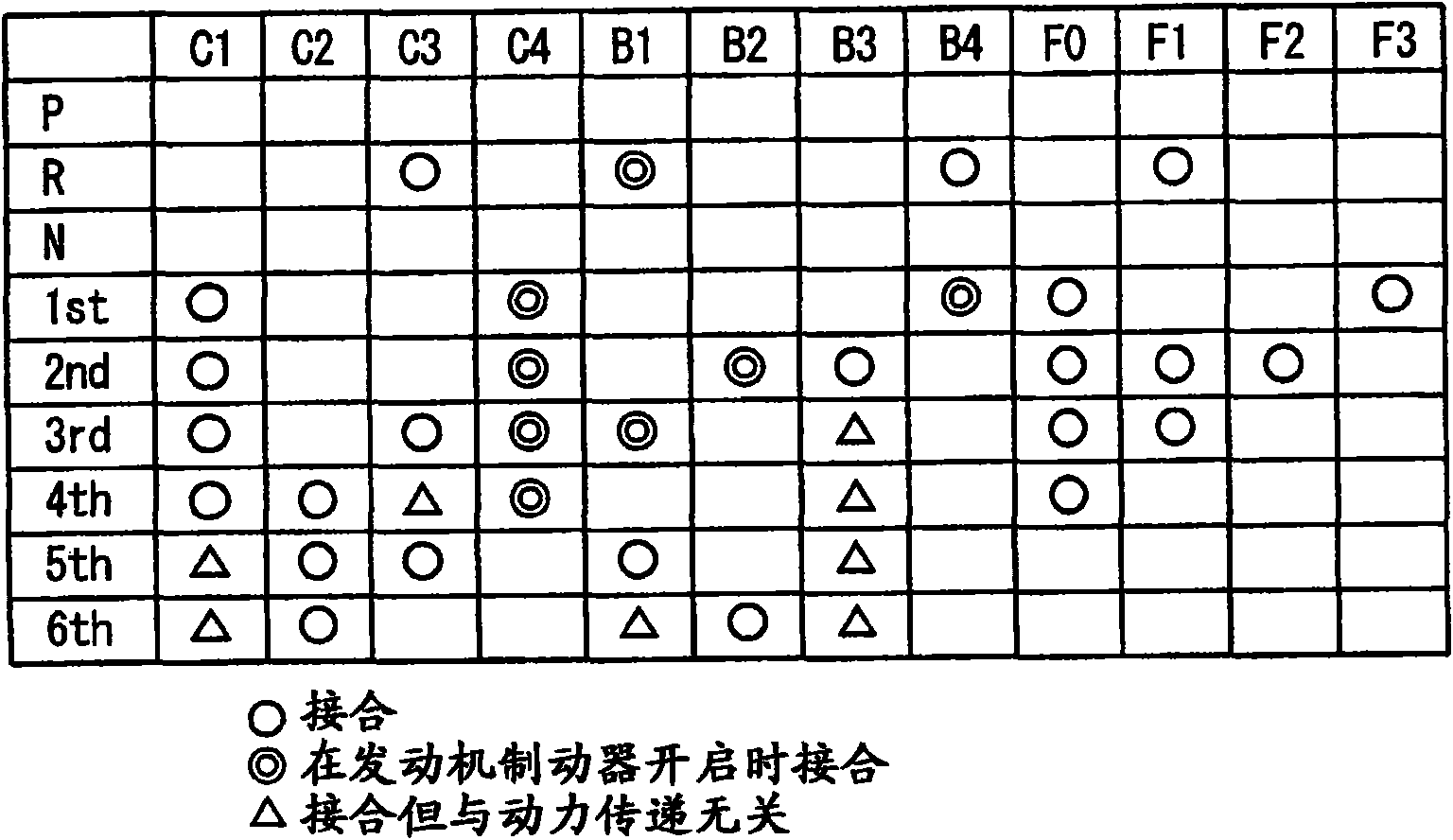

[0039] refer to figure 1 , the drive train of the vehicle mounted with the vehicle controller according to the present embodiment will be described. The vehicle controller according to this embodiment is specifically composed of figure 1 The ECU (Electronic Control Unit) 1000 shown is implemented.

[0040] Such as figure 1 As shown, the powertrain of the vehicle includes an engine 100 , an automatic transmission 320 and an ECU 1000 . The automatic transmission 320 includes a torque converter 200 as a fluid coupling and a transmission mechanism 300 formed of a planetary gear device.

[0041] Although the automatic transmission 320 is described as a gear type automatic transmission in the present embodiment, it may be any automatic transmission having friction engagement elements engaged at least when the vehicle is started. For example, a continuously variable automatic transmission having a transmission mechanism that continuously changes a transmission ratio using a belt ...

no. 2 example

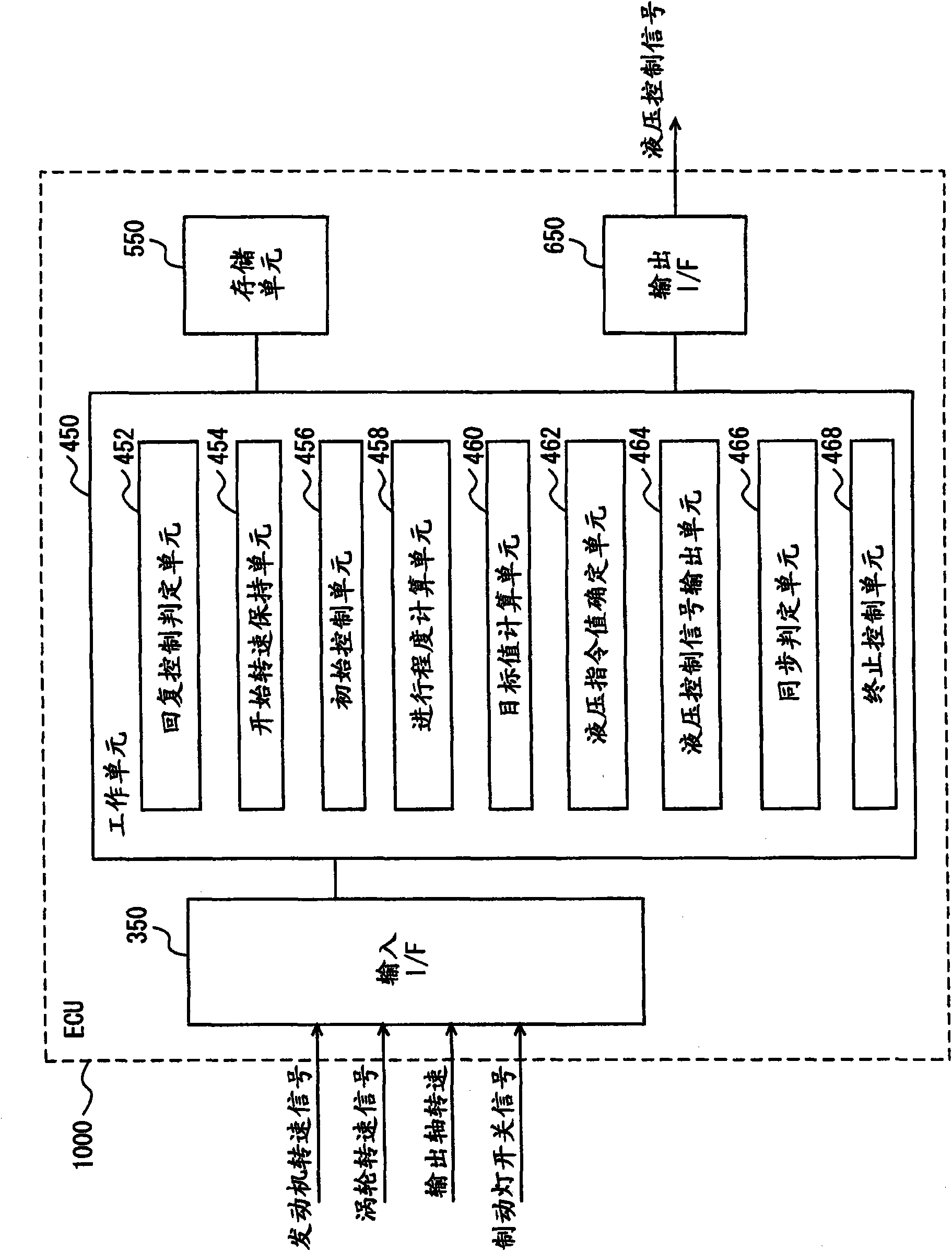

[0114] A vehicle controller according to a second embodiment will be described below. The vehicle controller according to the present embodiment differs from the configuration of the above-described vehicle mounted with the vehicle controller according to the first embodiment in the operation of the functional blocks of ECU 1000 . Except for this point, its configuration is the same as that of the vehicle mounted with the vehicle controller according to the first embodiment described above. The same components are denoted by the same reference numerals, and their functions are also the same. Therefore, its detailed description will not be repeated.

[0115] In the present embodiment, ECU 1000 is characterized in that the slope of the turbine rotational speed is set every time there is a transition between a plurality of periods (hereinafter referred to as stages) determined by the degree of progress of return control, and at the set timing The target turbine rotational speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com