Manufacturing method of woolen felt drawings

A production method and wool technology, which are applied in the process of producing decorative surface effects, decorative arts, special decorative structures, etc., can solve the problems of complex production process and low efficiency, and achieve simple production process, strong three-dimensional effect, and color. rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

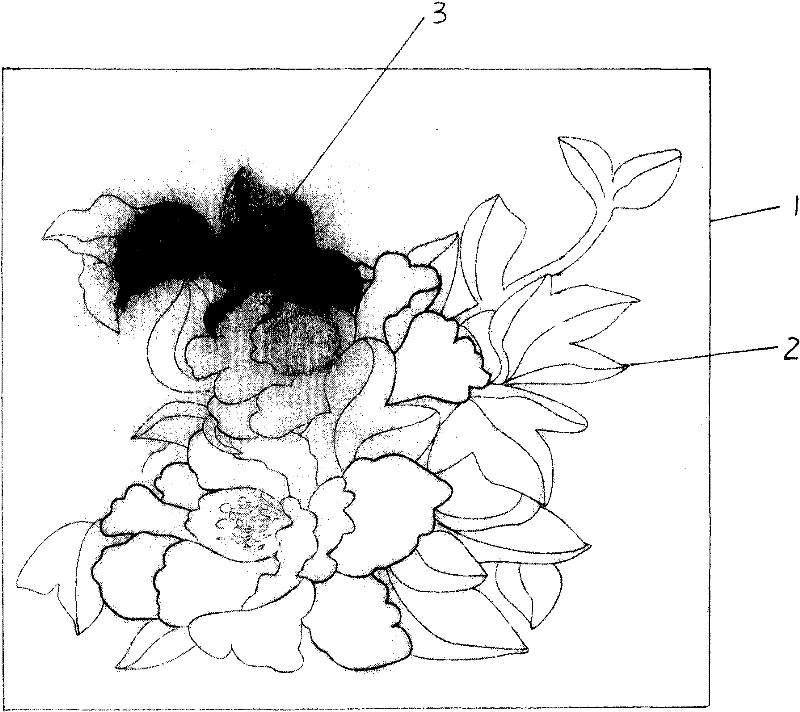

[0022] Embodiment: Prepare a piece of wool felt painting of "Peony Wealth and Nobility".

[0023] Its production process is as follows:

[0024] 1) Print the line drawing of "Peony Wealth and Nobility" on a 30CM*30CM wool felt sheet for later use;

[0025] 2) Dye the wool raw material into multiple colors, and compile the color number for standby;

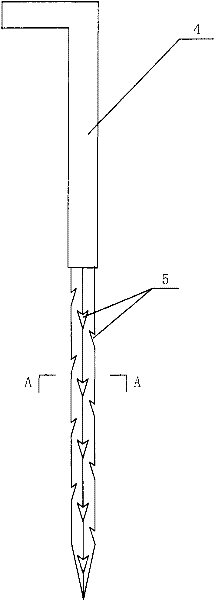

[0026] 3) According to the reference picture, mark the appearance, color and number of the various color blocks on the wool felt sheet and the poking method used. Then put the wool of the required color into the corresponding outline of the line drawing of the wool felt sheet, and then use a poking needle to poke continuously along the edge of the outline at an angle of 45 degrees, so that the wool on the outline line is fixed on the wool felt sheet, and then Then the wool in the middle is continuously stabbed vertically with a poking needle, so that the wool in the middle is tightly attached to the wool felt. In the picture, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com