Air conditioning unit and method for detecting oil level of compressor thereof

An air conditioner, oil level detection technology, applied in air conditioners, compressors, and multi-line fields to improve stability and ensure safe and stable operation.

Active Publication Date: 2010-08-25

GREE ELECTRIC APPLIANCES INC

View PDF0 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem of judging the oil level of the compressor in the high-pressure chamber, and to provide an air conditioner and a method for detecting the oil level of the compressor. Judging whether the oil level is lower than the normal working oil level, providing a reliable reference for the system to perform oil equalization action, and ensuring the safe and stable operation of the high-pressure chamber compressor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

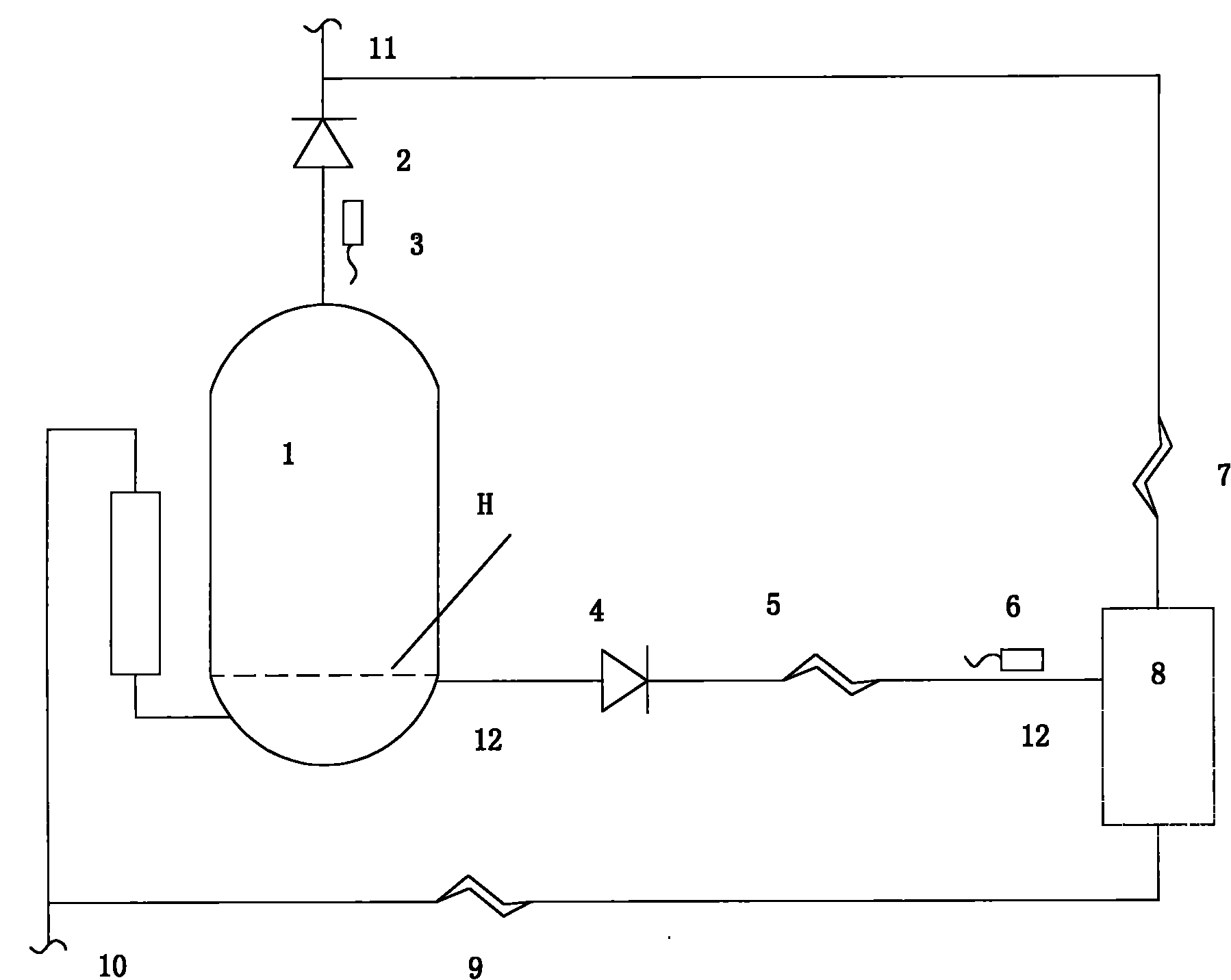

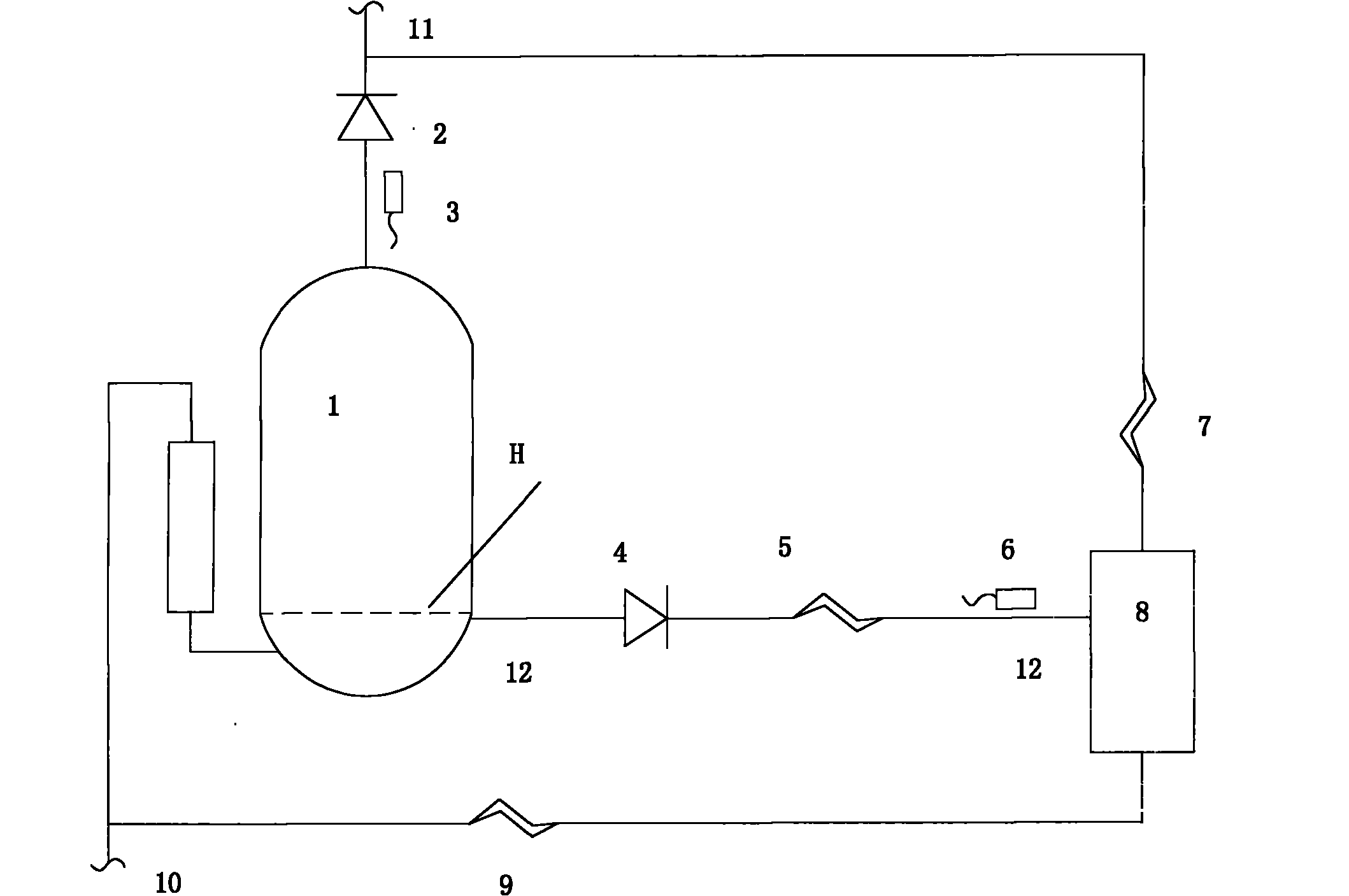

The invention aims to solve the problem of oil level judgment for a high pressure chamber compressor and provides an air conditioning unit and a method for detecting the oil level of a compressor thereof. The air conditioning unit is provided with a compressor part with an oil level detector, which can accurately judge whether the oil level is lower than the normal work oil level in the operation process of the compressor, provides reliable reference for the system to perform oil equalization operation and ensures safe and stable operation of the high pressure chamber compressor. The compressor part of the air conditioning unit also has the oil level detector which comprises an oil storage tank, an oil equalization tube connected to the normal oil level position of the compressor, and a first check valve and a first capillary tube which are arranged on the oil equalization tube; the two ends of the oil equalization tube are respectively connected with a casing and the oil storage tank of the compressor; one end of the first capillary tube close to the oil storage tank is provided with a first thermal bulb; the exhaust port of the compressor is provided with a second thermal bulb; and the first thermal bulb and the second thermal bulb are electrically connected with a control component.

Description

Air-conditioning device and method for detecting oil level of its compressor technical field The invention belongs to the technical field of air conditioners, in particular to the technical fields of multiple machines and compressors. Background technique In the field of air-conditioning technology, in a multi-line system in which multiple compressors operate in parallel, the oil balance between compressors is a key technical issue that affects system stability. For low-pressure chamber compressors, oil equalization between compressors can be achieved by setting oil-air balance pipes. As for the high-pressure chamber compressor, since the oil chamber is at the high-pressure end, the oil balance pipe cannot be directly used for oil equalization. When the oil level is unbalanced, the refrigeration oil must be evenly distributed through a specific oil equalization process. Accurately judging the oil level of the compressor is a necessary condition for the oil equalization pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F25B1/00F25B31/00F25B49/02

Inventor 沈军苏东波彭爱华

Owner GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com