Connector

A connector and connecting nut technology, which is applied in the direction of connection, connecting parts of devices, and devices for connecting/disconnecting connecting parts, etc., can solve the problems of long production time, poor consistency, unsuitable for insulators, etc., to ensure stability stability, consistency, and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

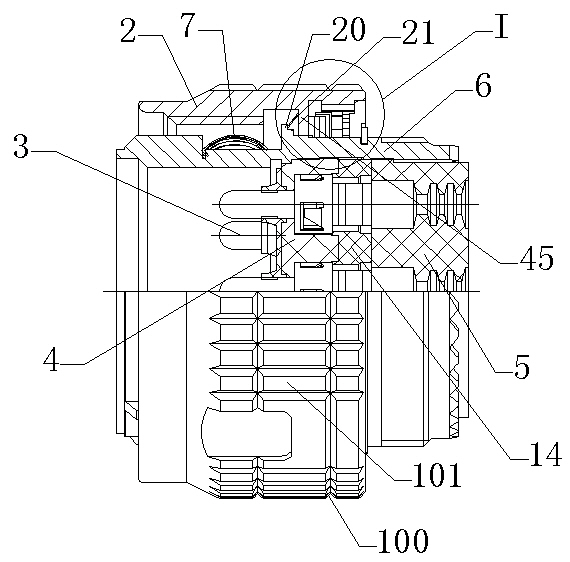

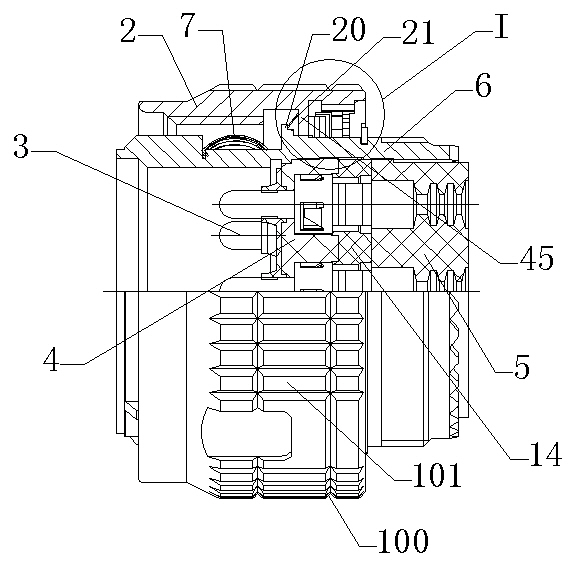

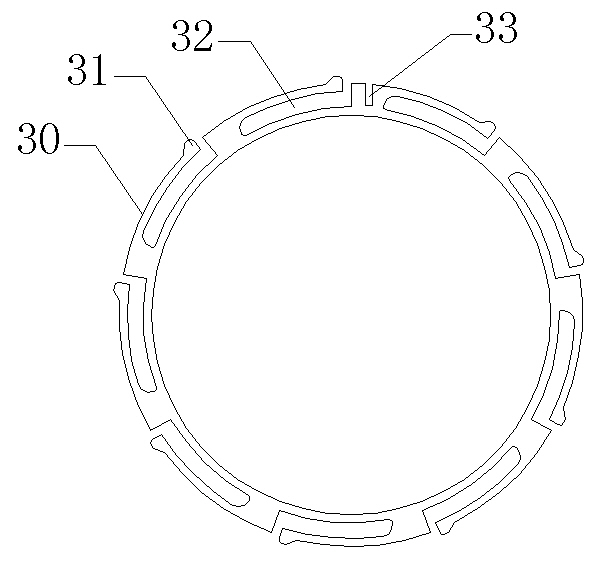

[0027] As shown in Figures 1, 2, 3, 4, 5, and 6, a connector of the present invention includes a conductive connector housing 6, and the connector housing 6 has a cavity through the front and back, and the cavity is from the front to the front. Afterwards, the first connector insulator 4, the second connector insulator 14 and the sealing wire body 5 are installed in sequence, and a coaxial connector is opened in the first connector insulator 4, the second connector insulator 14 and the sealing wire body 5. The contact piece installation hole, the connector contact piece 3 is fixedly installed in the connector contact piece installation hole. The first connector insulator 4 realizes forward thrust fit through the stepped positioning surface provided at the front end, and a rectangular positioning groove is opened on the inner surface of the connector housing corresponding to the position of the second insulator 14, and the depth of the rectangular positioning groove is very larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com